Hf bonding your shunt module, Establishing noise zones – Rockwell Automation 2090-SRxxx External Shunt Modules Installation Instructions User Manual

Page 6

Publication 2090-IN004B-EN-P — June 2008

6 External Shunt Modules

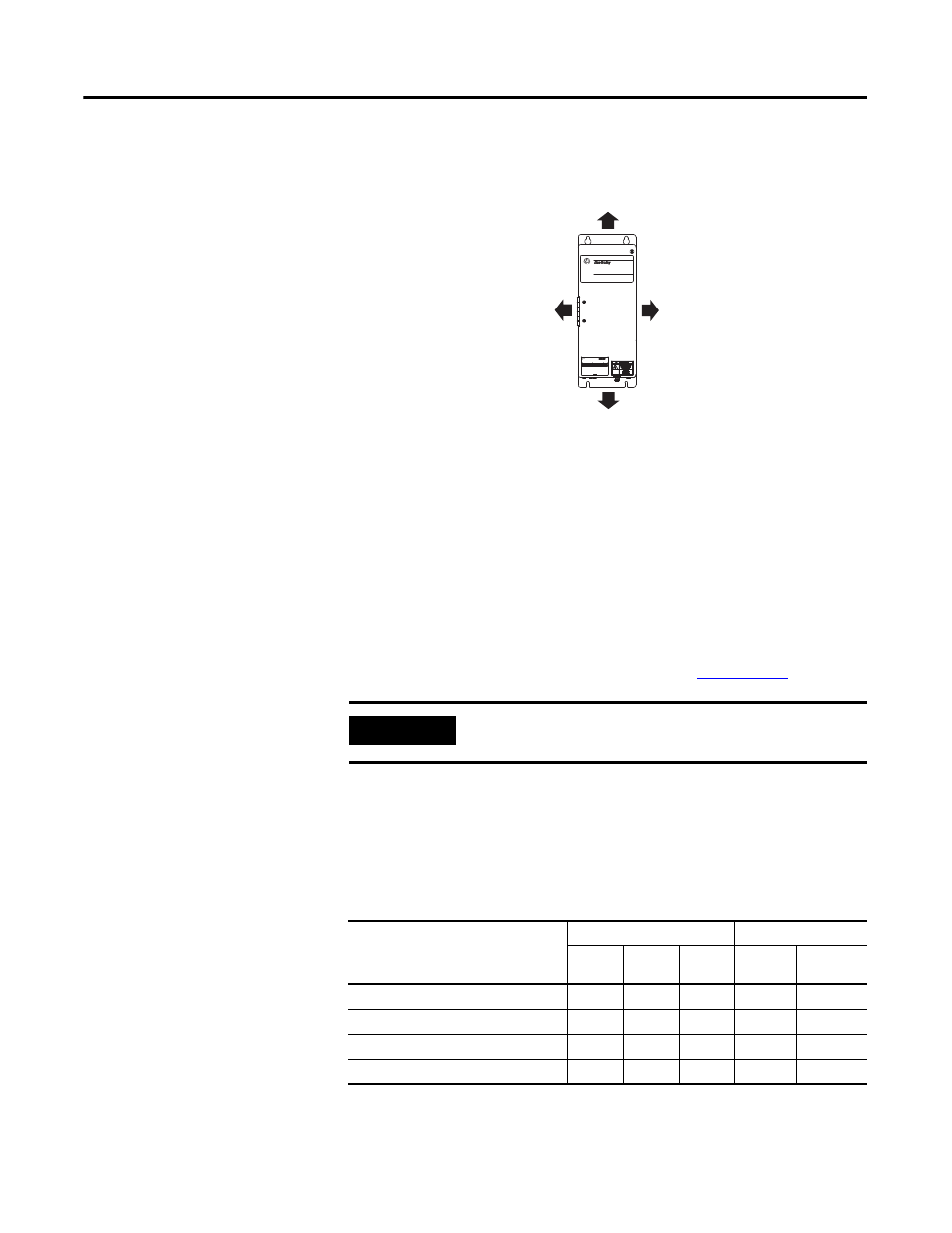

Minimum Clearance Requirements (outside the enclosure)

HF Bonding Your Shunt Module

Bonding is the practice of connecting metal chassis, assemblies,

frames, shields, and enclosures to reduce the effects of

electromagnetic interference (EMI). For more information on the

concept of high-frequency (HF) bonding, the ground plane principle,

and electrical noise reduction, refer to System Design for Control of

Electrical Noise Reference Manual, publicatio

.

Establishing Noise Zones

This table provides the zoning requirements of cables connecting to

the external shunt module.

1394 Digital Servo Controller

3600W Shunt Module

BULLETIN 1394 3600W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

150 mm (6.0 in.) clearance

for airflow and installation.

254 mm (10.0 in.) clearance

for airflow and installation.

Bulletin 1394 and 2090

External Shunt Modules

(1394-SR36Ax module is

shown in this example.)

IMPORTANT

To improve the bond between the drive system and subpanel,

construct your subpanel out of zinc plated (paint-free) steel.

Wire/Cable

Zone

Method

Very

Dirty

Dirty

Clean

Ferrite

Sleeve

Shielded

Cable

COL, DC+ (shielded option)

X

X

COL, DC+ (unshielded option)

X

Thermal switch

X

X

Fan (if present)

X