Fuse protection and blown fuse diagnostics – Rockwell Automation 1746-XXXX SLC 500 Digital I/O Modules Installation Instructions User Manual

Page 7

SLC 500 Digital I/O Modules 7

Publication 1746-IN027D-EN-P - December 2012

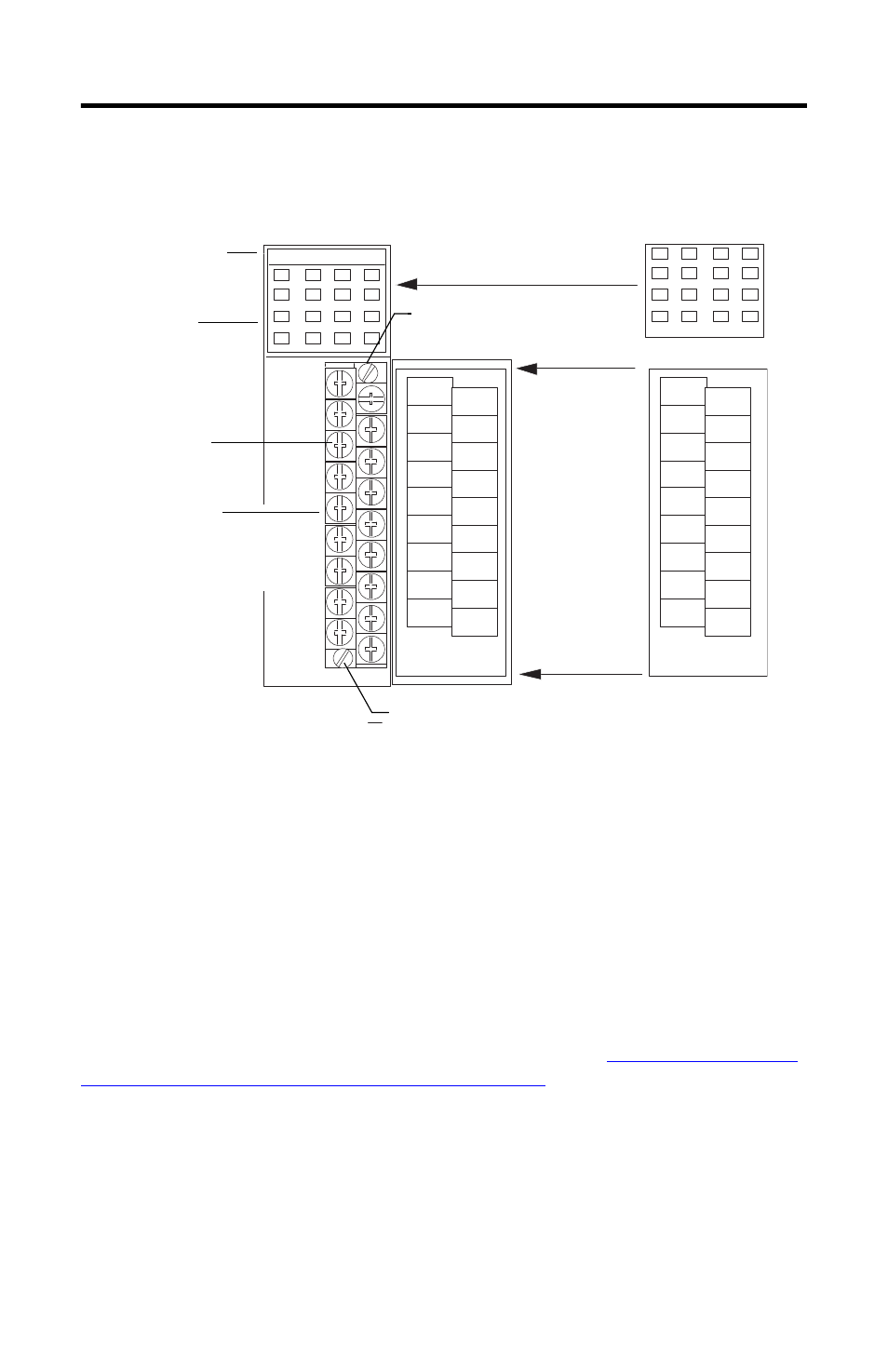

Installing Octal Labels

Fuse Protection and Blown Fuse Diagnostics

This section describes fusing characteristics for the following modules:

• 1746-OBP16

• 1746-OVP16

• 1746-OAP12

Fuse Protection (1746-OBP16 and 1746-OVP16 modules)

The fuse on the 1746-OBP16 and 1746-OVP16 modules (shown on

Fuses for 1746-OBP16 and 1746-OVP16 Modules on page 9

) provides short-circuit protection

for 13 mm

2

(16 AWG) or larger wiring to external loads. In the event of a short circuit on an

output channel, it is likely that the transistor associated with that channel will be damaged. In

this event, the module should be replaced or the load moved to a spare output channel.

The fuse does not provide overload protection. In the event of an overload on an output channel,

it is likely that the fuse will not blow and the transistor associated with that channel will be

damaged. To provide overload protection for your application, user-supplied fuses should be

installed externally and properly sized to match your individual load characteristics.

OCTAL

1746-xxxx (OCTAL)

Octal Door Label

1746-xxxx

Octal Filter Label

Upper retaining screw max torque

= 0.6 Nm (5.3 lb-in.)

Module Color Bar

Lower retaining screw max torque

= 0.6 Nm (5.3 lb-in.)

Removable

Terminal Block

Beveled Edge

Terminal Wiring

Max 2mm

2

(14 AWG)

Max 2 wires per terminal

Max torque: 0.9 Nm (8 lb-in.)