Panel mounting – Rockwell Automation 1769-IF8 Compact 1769-IF8 Analog Input Module User Manual

Page 6

6 Compact I/O 1769-IF8 Analog Input Module

Publication 1769-IN067B-EN-P - September 2005

Panel Mounting

Mount the module to a panel using two screws per module. Use M4 or #8 panhead

screws. Mounting screws are required on every module.

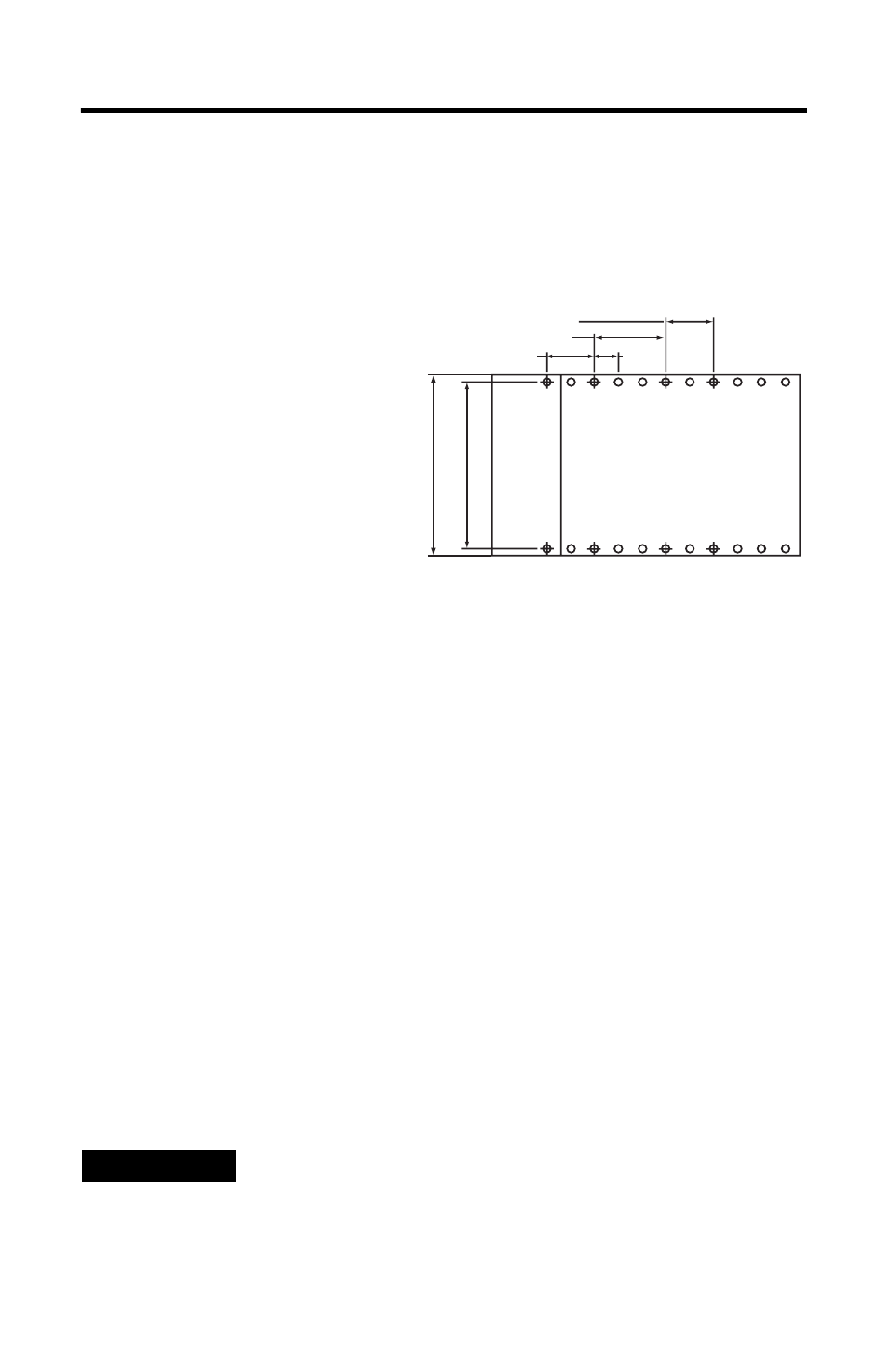

Panel Mounting Using the Dimensional Template

Panel Mounting Procedure Using Modules as a Template

The following procedure allows you to use the assembled modules as a template

for drilling holes in the panel. If you have sophisticated panel mounting equipment,

you can use the dimensional template provided on page 6. Due to module

mounting hole tolerance, it is important to follow these procedures:

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel and check for proper hole alignment.

6. Attach the modules to the panel using the mounting screws.

7. Repeat steps 1 to 6 for any remaining modules.

NOTE

If mounting more modules, mount only the last one of this

group and put the others aside. This reduces remounting time

during drilling and tapping of the next group.

l Mounting

Ho

st

Controller

Refer to host controller documentation for this dimension.

Spacing for single-wide modules 35 mm (1.378 in).

NOTE: Overall hole spacing

tolerance: ±0.4 mm (0.016 in.)

Spacing for one-and-a-half-wide modules 52.5 mm (2.067 in).

Locate holes every 17.5 mm (0.689 in) to allow for a

mix of single-wide and one-and-a-half-wide modules

(e.g., 1769-OA16).