Sls test procedure – Rockwell Automation 1000 Safety Lockout System User Manual

Page 27

Publication 1000-UM001B-US-P - July 2000

Troubleshooting Guide 5-3

SLS Test Procedure

If an SLS box needs to be removed from the main control panel, it can be

tested as follows.

Wiring diagram:

Y-155798 Rev. M = SLS box

Y-156328 Rev. B = SLS switch

Y-156386 Rev. B = test procedure control panel

In addition to the normal Allen-Bradley test procedure, the following should

also be done:

1. Connect test control panel per Y-156386 Rev. B at PLC connector and

power test panel with 24V DC separate control.

2. Connect four SLS switches wired per Y-156328 Rev. B.

3. Apply 480V or 400V three-phase to line side of isolation contactor.

4. Turn the four SLS switches to ON position.

5. Energize 1SR with selector switch on test control panel.

6. Observe all LEDs in SLS box for condition. Observe pilot lights on test

control panel for condition. SR, 1SR, IC, and 1CR should be energized.

7. All SLS switch SAFE lights should be off.

8. Measure DC voltage on power supply output. If necessary, adjust to

27V.

9. Check voltage on secondary of CCT.

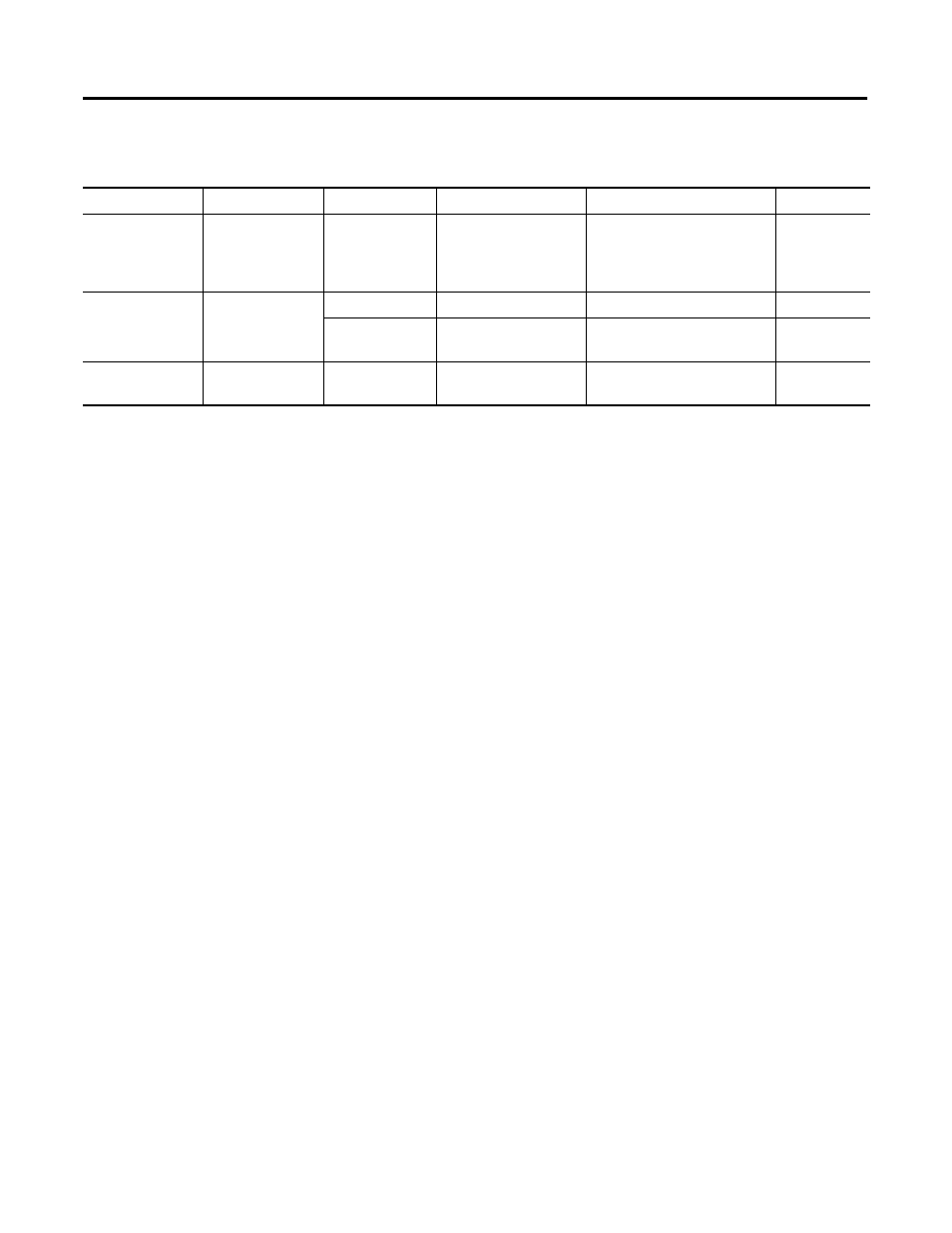

Table 5.B SLS Switch

Problem

Component

Possible Cause

Check

Suggested Action

Repairable?

Does not

illuminate with all

other circuitry

checking OK

Pilot light

Burned out bulb

Loose

connections

Connections

Replace bulb.

Tighten connections.

Yes

Contacts do not

operate properly

SLS switch

Bad switch

Continuity and operation Replace.

No

Handle

mechanism

For operation

Replace.

No

Contacts do not

operate properly

SLS switch

auxiliary contact

Bad contact

Continuity and operation Replace.

No