Rockwell Automation 1391ES AC Servo Controller User Manual

Page 26

Description of Operation

Chapter 4

4-24

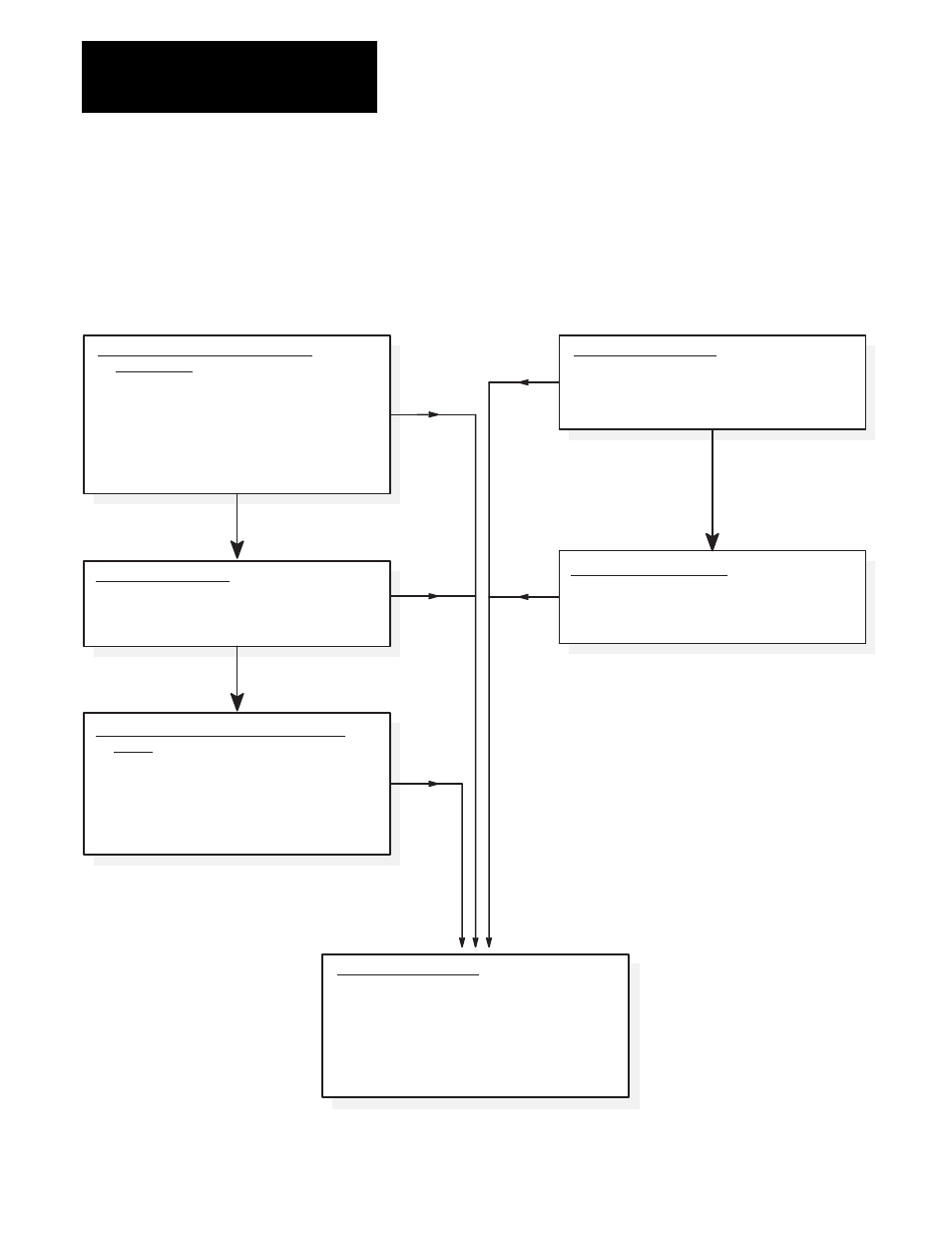

Power-Up/Down Sequence

Figure 4.4 describes the various steps involved in the power-up/down

sequence of the 1391B-ES controller.

Figure 4.4

Controller Power-Up / Down Sequence

Application of 240V AC to Isolation

Transformer

a) Logic power supplies and base drive circuits

power-up.

b) Apply 115V AC to contactor.

c) Power bus charges.

d) If no faults are encountered, the DROK relay

energizes. Controller is ready to receive

customer enable signal.

Enable Signal is Applied Prior to 36V AC

Power

a) When 36V AC power is applied, fault circuits

detect that the enable signal is already applied.

Random fault conditions occur.

b) Re-application of enable after resetting the

controller and with 36V AC power still

present, will energize the controller.

Enable Signal Removed

a) Motor will regenerate to a stop.

b) Output power stage is disabled.

c) DROK relay maintains a no fault status.

Fault Condition Occurs

a) Controller output stage disabled.

b) DROK relay is de-energized and a fault is

latched.

c) If contactor is wired to the DROK relay in a

stop string, contactor will open and the shunt

regulator will discharge the power bus

supply.

POWER-UP

SEQUENCE

240V AC Power Removed

a) Logic and DC link power supplies begin

decaying to zero volts.

b) Undervoltage (fault) condition occurs.

POWER-DOWN

SEQUENCE

Enable Signal Applied

Minimum of 100 ms after Contactor is Closed

a) Base drive enabled and will respond to

customer command inputs.

Fault

Fault

Fault

Fault

Fault