Rockwell Automation 20C-DG01 PowerFlex 700H AC Drive Safe Torque Off Option User Manual

Page 20

20

Rockwell Automation Publication 20C-UM001B-EN-P - June 2011

Chapter 2 Installation and Wiring

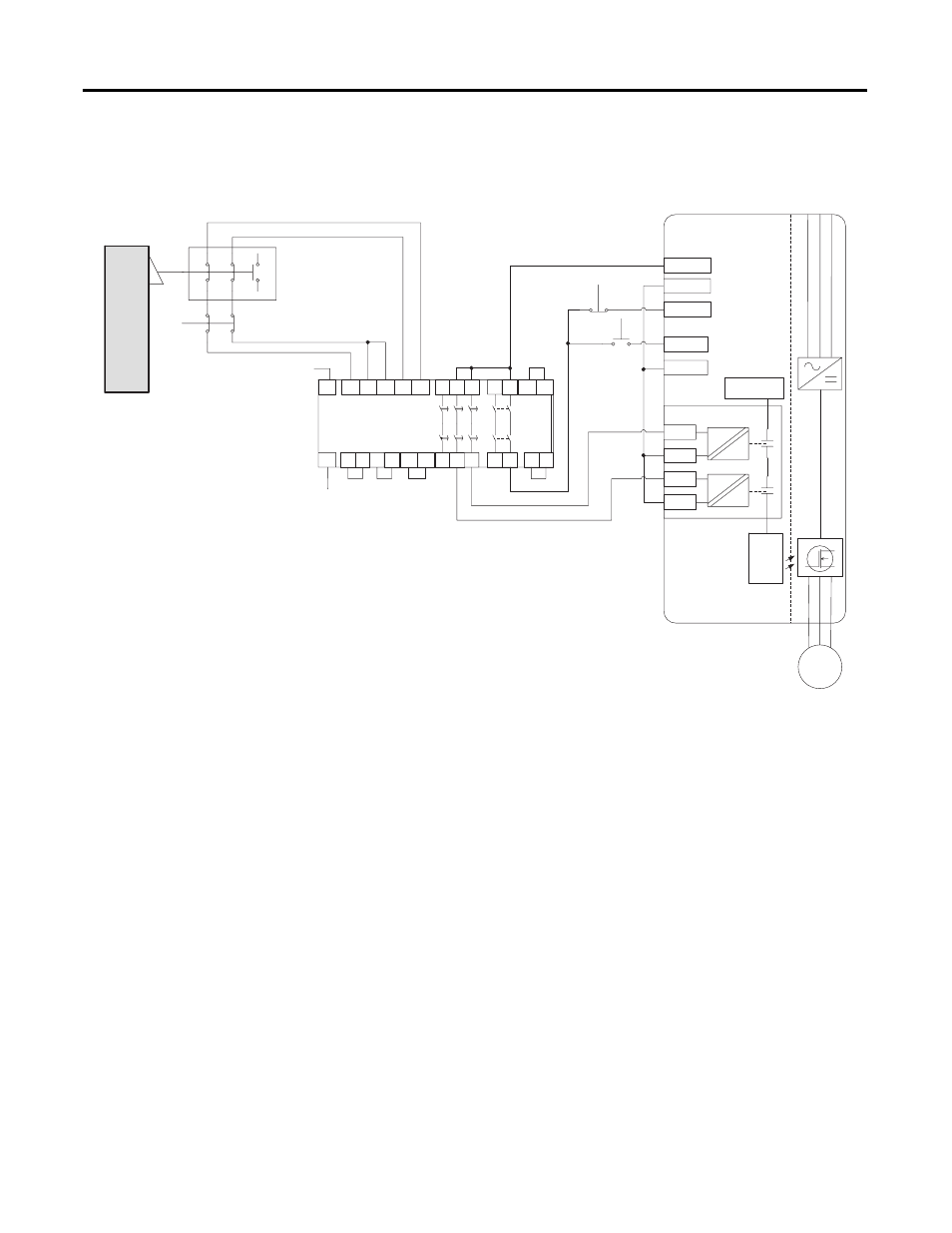

Figure 3 - Example 2 - Drive Safe Torque Off Connections with Controlled Stop

Action and Emergency Stop Operation, Dual Channel, with External Relay

Circuit Status

– Circuit shown with guard door and E-stop closed and system

ready for normal operation.

Operating Principle

– Opening the guard door or pressing the E-stop button

will switch the input circuits (S11-S12 & S21-S22) to the Minotaur monitoring

safety relay unit. The immediate output circuits (23-24) will issue a Stop

command and the drive will follow the programmed stop configuration. After

the programmed delay, the timed output circuits (47-48 & 57-58) will cause the

Safe Torque Off option to go to a safe state (off ). If the motor has not stopped

rotating, it will coast to stop. The drive can be configured to display a “Gate

Disable” fault or alarm (F59) on the HIM when the gate control circuit is

disabled. To restart the drive, the Minotaur safety relay inputs (S11-S12, S21-

S22) must first be ready for normal drive operation, the drive fault must be

cleared and a valid start command must be issued to the drive.

Application Considerations

– When used, the E-stop button must utilize

direct-opening contacts. The button must latch to an open state when the

contacts open. The button must be red with a yellow background.

Fault Detection

– A redundant (two) set of double break contacts on the Trojan

gate interlock are designed to ensure that at least one signal is sent to the Safe

Stop

Start

23

13

Y1

S12

S11

A1

24

14

Y2

A2

Minotaur

MSR138DP

24V DC

Com

S22

S52

S21

47

37

48

38

57

58

S33 S34

X2

X1

X4

X3

Y40

Y39

M

3 SD2+

2 SD1-

4 SD2-

1 SD1+

Gate

Control

Circuit

Gate Enable

PowerFlex 700H

AC Drive

AC Line

Input Power

+24VDC

Stop

Start

24V Com

DigIn Com

GuardMaster

Trojan

E-Stop

Latching

Button

+24V DC

Safe-Off Option Board