Rockwell Automation 20B PowerFlex 700 Power Jumpers User Manual

Page 6

Publication 20B-IN021B-EN-P

6

PowerFlex 700 Power Jumpers

Fra

m

e

Vo

lt

ag

e

Code

C

u

rrent

Ra

ti

ng

Factory Default Jumper Settings

Power Source Type

MOV/Input Filter

Caps

(1) (2)

DC Bus Common

Mode Caps

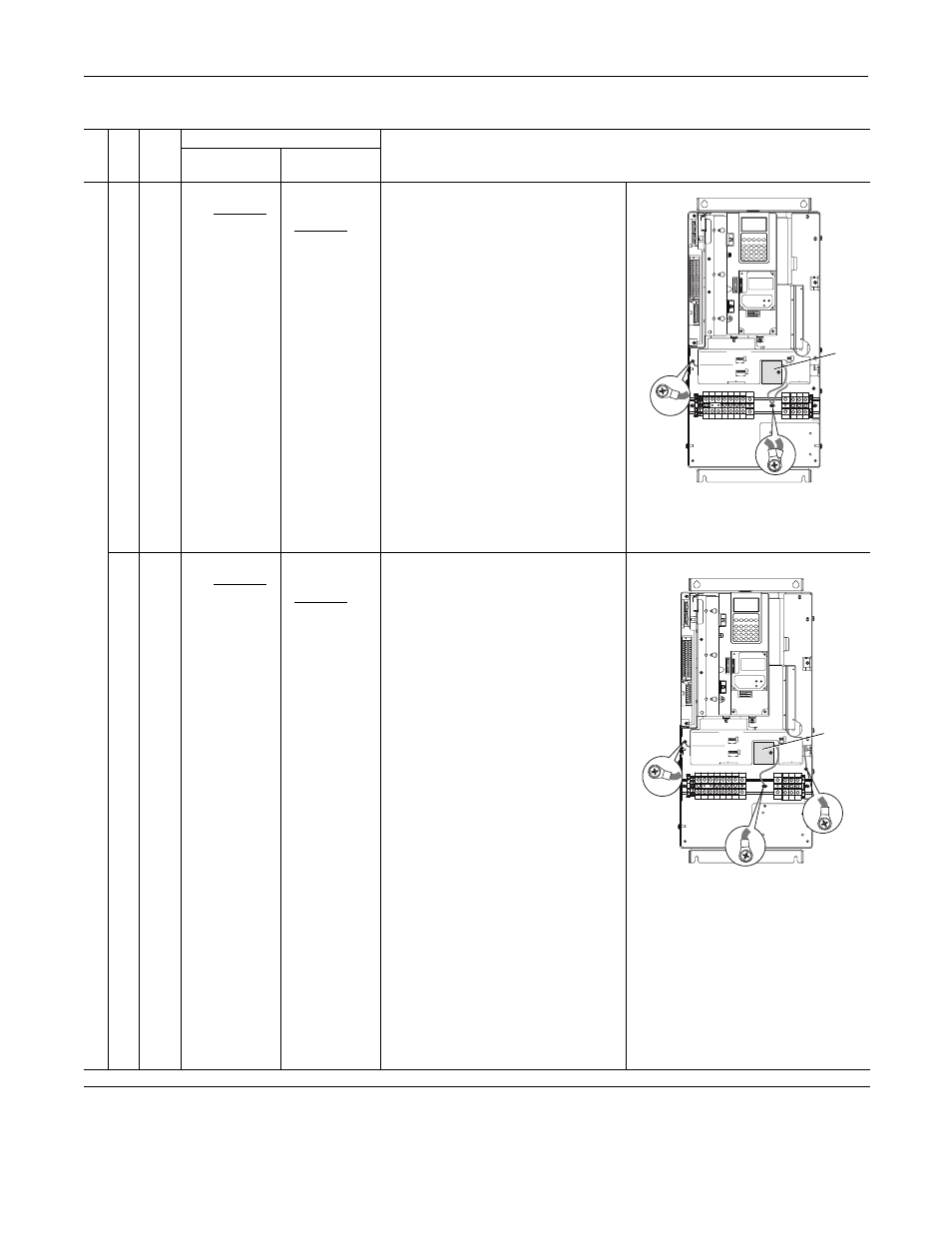

5

C

F

W

140

052

060

Two green/yellow

wires connected

to the Power

Terminal Block rail

Green/yellow wire

to CM Cap Board

is connected to

ground

Solid Ground

1. CM Cap jumper wire should be connected

to ground with a metal screw. Verify. If

necessary, remove the nylon screw/spacer

and insert a metal M5 x 8 screw. Torque to

3.2 N•m (28 lb•in).

2. MOV/Input Filter Cap jumper wires should

be connected to ground with a metal screw.

Verify. If necessary, remove the nylon screw/

spacer and insert a metal M5 x 12 screw.

Non-Solid Ground

1. CM Cap jumper wire should be insulated

from ground with a nylon screw/spacer.

Verify. If necessary, remove the metal screw

and insert a M5 x 15 nylon screw/spacer.

2. MOV/Input Filter Cap jumper wires should

be insulated from ground with a nylon

screw/spacer. Verify. If necessary, remove

the metal screw and insert a

M5 x 20 nylon screw/spacer.

E

F

T

W

077

082

099

098

Two green/yellow

wires connected

to chassis ground

Green/yellow wire

to CM Cap Board

is connected to

ground

Solid Ground

1. CM Cap jumper wire should be connected

to ground with a metal screw. Verify. If

necessary, remove the nylon screw/spacer

and insert a metal M5 x 8 screw. Torque to

3.2 N•m (28 lb•in).

2. MOV jumper wire should be connected to

ground with metal screws. Verify. If

necessary, remove the nylon screw/spacers

and insert a metal M5 x 12 screws.

3. Input Filter Cap jumper wire should be

connected to ground with a metal screw.

Verify. If necessary, remove the nylon screw/

spacer and insert metal M5 x 8 screw.

Non-Solid Ground

1. CM Cap jumper wire should be insulated

from ground with a nylon screw/spacer.

Verify. If necessary, remove the metal screw

and insert a M5 x 15 nylon screw/spacer.

2. MOV jumper wire should be insulated from

ground with a nylon screw/spacer. Verify. If

necessary, remove the metal screws and

insert a M5 x 20 nylon screw/spacer.

3. Input Filter Cap jumper wire should be

insulated from ground with a nylon screw/

spacer. Verify. If necessary, remove the

metal screws and insert a M5 x 15 nylon

screw/spacer.

Frame 5 continued on next page

(1)

AC input drives only. MOV’s and input filter caps do not exist on DC input drives.

(2)

When removing MOV’s, the input filter capacitor must also be removed.

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

POWER TERMINAL RATINGS

WIRE RANGE: 6-1/0 AWG (16-35 MM2)

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

GROUND TERMINAL RATINGS (PE)

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM2)

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

17

21

INPUT AC

OUTPUT

Optional

Communications

Module

9

CM Cap

MOV

MOV / Input Filter Cap

WIRE RANGE: 14-1/0 AWG (2.5-35 MM2)

TORQUE: 32 IN-LB (3.6 N-M)

STRIP LENGTH: 0.67 IN (17 MM)

USE 75 C CU WIRE ONLY

POWER TERMINAL RATINGS

WIRE RANGE: 6-1/0 AWG (16-35 MM2)

TORQUE: 44 IN-LB (5 N-M)

STRIP LENGTH: 0.83 IN (21 MM)

GROUND TERMINAL RATINGS (PE)

300 VDC EXT PWR SPLY TERM (PS+, PS-)

WIRE RANGE: 22-10 AWG (0.5-4 MM2)

TORQUE: 5.3 IN-LB (0.6 N-M)

STRIP LENGTH: 0.35 IN (9 MM)

17

21

INPUT AC

OUTPUT

Optional

Communications

Module

9

PE

CM Cap

MOV

MOV

Input Filter

Cap