Jumper settings and locations, 4powerflex 700 power jumpers, Cm cap mov – Rockwell Automation 20B PowerFlex 700 Power Jumpers User Manual

Page 4: Cm cap

Publication 20B-IN021B-EN-P

4

PowerFlex 700 Power Jumpers

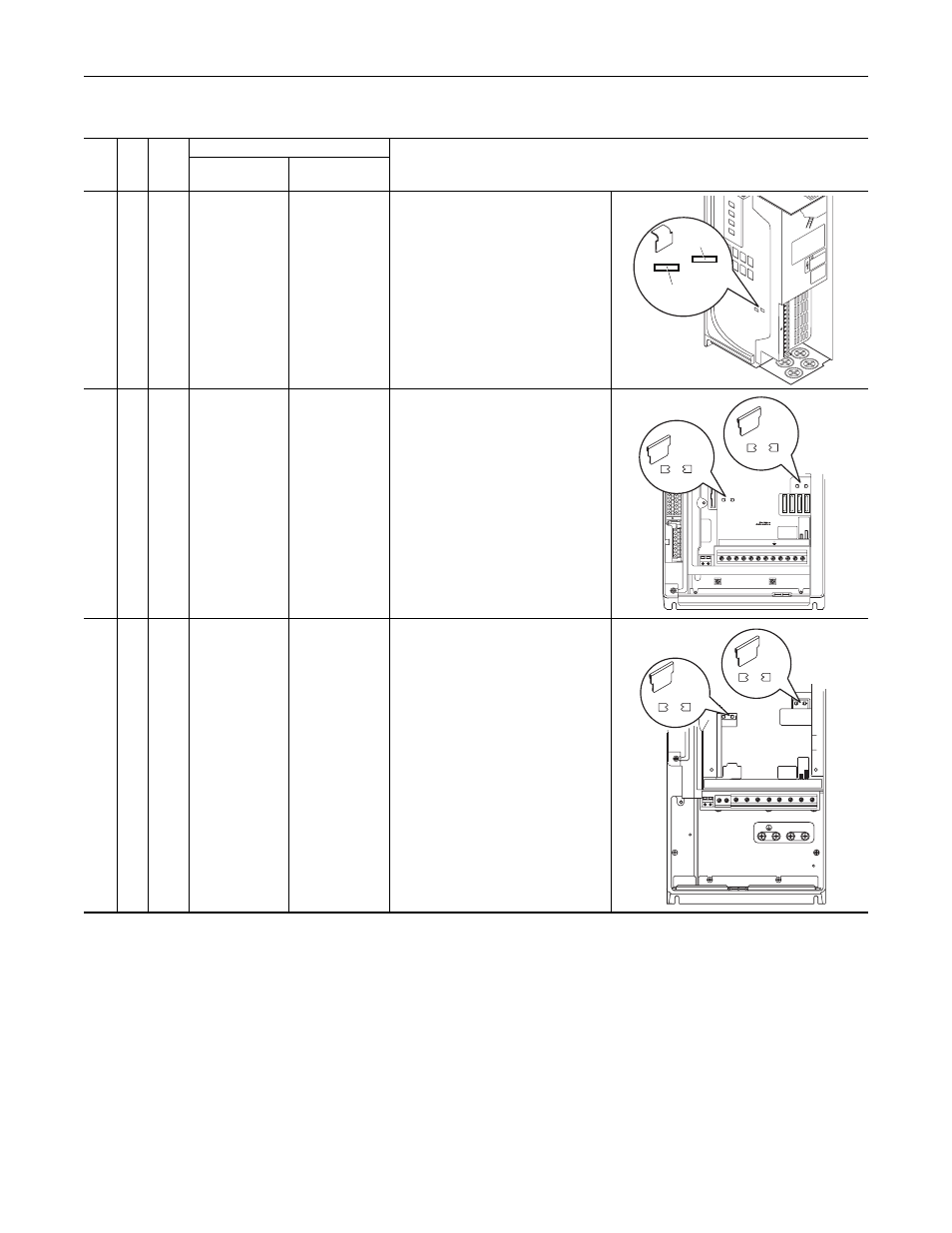

Jumper Settings and Locations

Fra

m

e

Vo

lt

ag

e

Code

C

u

rrent

Ra

ti

ng

Factory Default Jumper Settings

Power Source Type

MOV/Input Filter

Caps

DC Bus Common

Mode Caps

0…1

B

C

D

E

All

PE_B

Installed

PE_A

Installed

Solid Ground

• Remove the I/O Cassette (refer to the

User Manual for details). Verify that

jumpers are installed at the “PE_A” and

“PE_B” locations on the Power Board.

Non-Solid Ground

• Remove the I/O Cassette (refer to the

User Manual for details). Remove

jumpers at the “PE_A” and “PE_B”

locations on the Power Board.

2

B

C

D

E

All

PE_MOV

Installed

PE_CAP

Installed

Solid Ground

• Verify that jumpers are installed at the

“PE_CAP” and “PE_MOV” locations.

Non-Solid Ground

• Remove jumpers at the “PE_CAP” and

“PE_MOV” locations.

3…4

B

C

D

E

All

PE_MOV

Installed

PE-CAP

Installed

Solid Ground

• Verify that jumpers are installed at the

“PE_CAP” and “PE_MOV” locations.

Non-Solid Ground

• Remove jumpers at the “PE_CAP” and

“PE_MOV” locations.

BR1

BR2

DC+

DC–

PE

U/T1

V/T2

W/T3

R/L1

S/L2

T/L3

Use 75C

Wire Only

#10-#14 A

WG

Torque to 7 in-l

bs

!

DA

NGER

PE A

PE B

CM Cap

MOV

BR1 BR2 DC+ DC- U/T1 V/T2 W/T3

SHLD

SHLD

PE R/L1 S/L2 T/L3

PE 2

MOV-PE JMPR

PE 1

AUX IN+ AUX OUT–

75C Cu Wire

6 AWG [10MM

2

] Max.

12 IN. LBS.

1.4 N-M

} TORQUE

WIRE

STRIP

CONTR

O

L

PO

WER

PE 4

PE 3

MOV

PE_MOV

CM Cap

PE_CAP

BR1 BR2 DC+ DC- U/T1 V/T2 W/T3 R/L1 S/L2 T/L3

PE MOV

PE CAP

75C Cu Wire

3 AWG [25MM

2

] Max.

16 IN. LBS.

1.8 N-M

} TORQUE

WIRE

STRIP

CONTR

O

L

PO

WER

AUX IN

+ –

SHLD

SHLD

PE

75C Cu Wire

6 AWG [10MM2] Max.

BR1 BR2

12 IN. LBS.

1.4 N-M

} TORQUE

PE_CAP

PE_MOV

CM Cap

MOV