Corrosive resistance – Yamato Scientific Vacuum controller Vacuum controller User Manual

Page 13

11

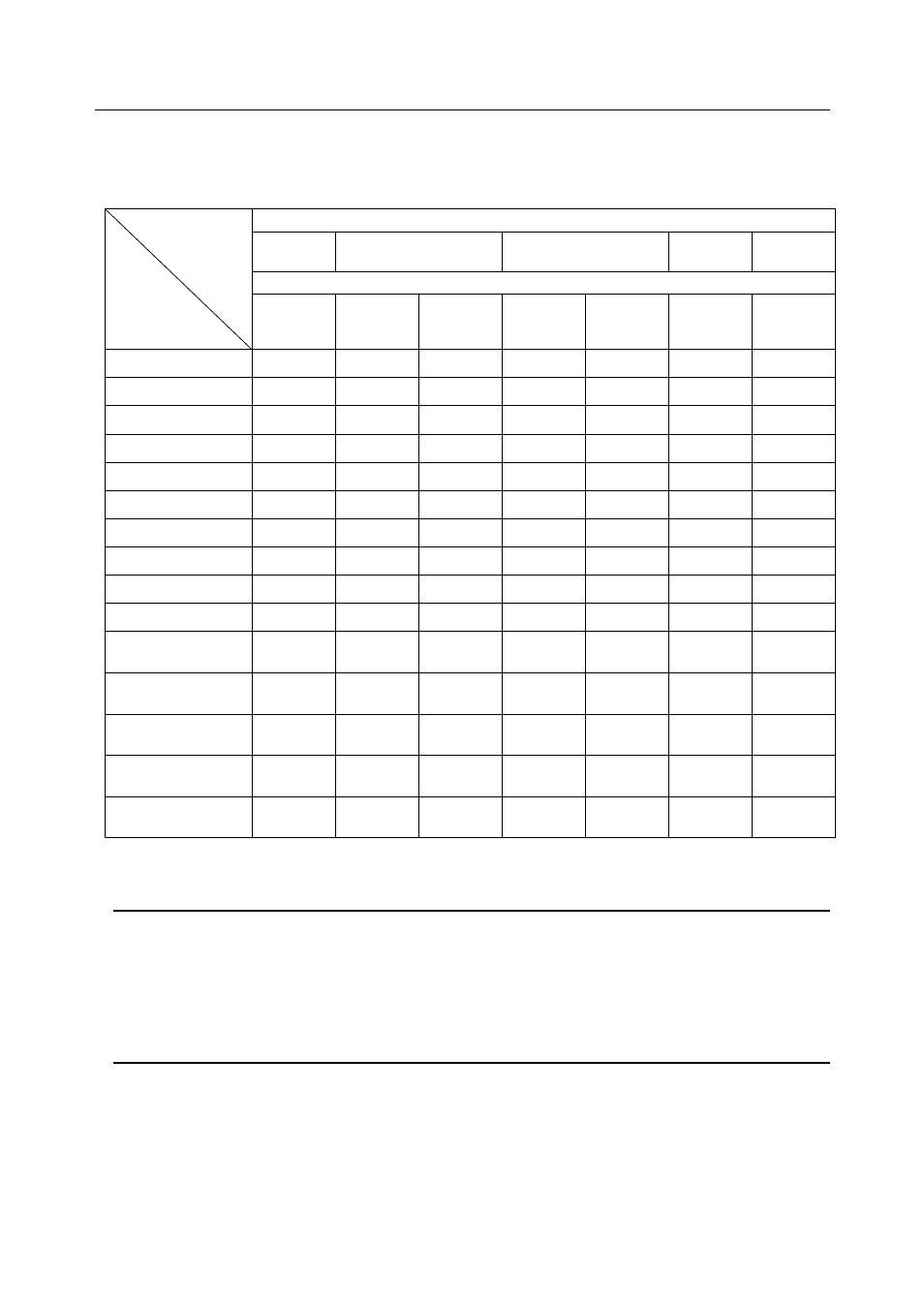

Corrosive Resistance

TABLE:

Corrosive resistance of the parts connected to gas

FPM: Fluoro Rubber, PTFE: Teflon

Part

Pressure

sensor

Solenoid valve

Solenoid valve armature

Piping

tube

Joint

Material

Silicon

ceramic

nickel

Brass

(body)

FPM

(O-Ring)

FPM

(sheet)

SUS

(body)

PTFE

Brass

Methyl alcohol

○

○

Ч

Ч

○

○

○

Ethyl alcohol

○

○

○

○

○

○

○

Isopropanol

○

○

○

○

○

○

○

Methyl chloride

×

○

○

○

○

○

○

Chloroform

×

○

○

○

○

○

○

Aceton

△

○

Ч

Ч

○

○

○

Methyl ethyl ketone

△

○

Ч

Ч

○

○

○

Benzene

×

○

○

○

○

○

○

Toluene

×

○

○

○

○

○

○

Ethyl acetate

△

○

Ч

Ч

○

○

○

Hydrochloric acid

(20

℃ under5%)

Ч

Ч

○

○

△

○

Ч

Hydrochloric acid

(20

℃ over5%)

Ч

Ч

○

○

Ч

○

Ч

Sulphuric acid

(20

℃ under5%)

Ч

Ч

○

○

△

○

Ч

Sulphuric acid

(20

℃ over5%)

Ч

Ч

○

○

Ч

○

Ч

Sodium hydroxide

(20

℃ under10%)

Ч

Ч

○

○

○

○

Ч

○ :suitable for use, △ :not recommended, × :unsuited

NOTE 1

The corrosion resistance above shows the case when samples are immersed in solvent or the

like. Since the product's gas-joints are exposed to low-concentrated steam that can not be

trapped by the condenser(cooler), the joints are not corroded soon. However some sort of

rubber might swell depending on the kind of solvent, or, frequency of use. If pressure in the

system is not held or an abnormality is shown, please contact us.

NOTE 2

Since the pressure detection circuit which is constructed in the pressure sensor is exposed,

care should be taken to see that no liquid touch it. If the aspirator is shutdown without

leaking the vacuum, it may cause a back-flow and sensor parts may be damaged by water

from the aspirator's bath.