Electric heater, Preparation, Installation – Titus VAB IOM User Manual

Page 6: Startup, Operation and maintenance, Vab installation manual

VAB Installation Manual

IOM-VAB-00

06-30-04

6 of 7

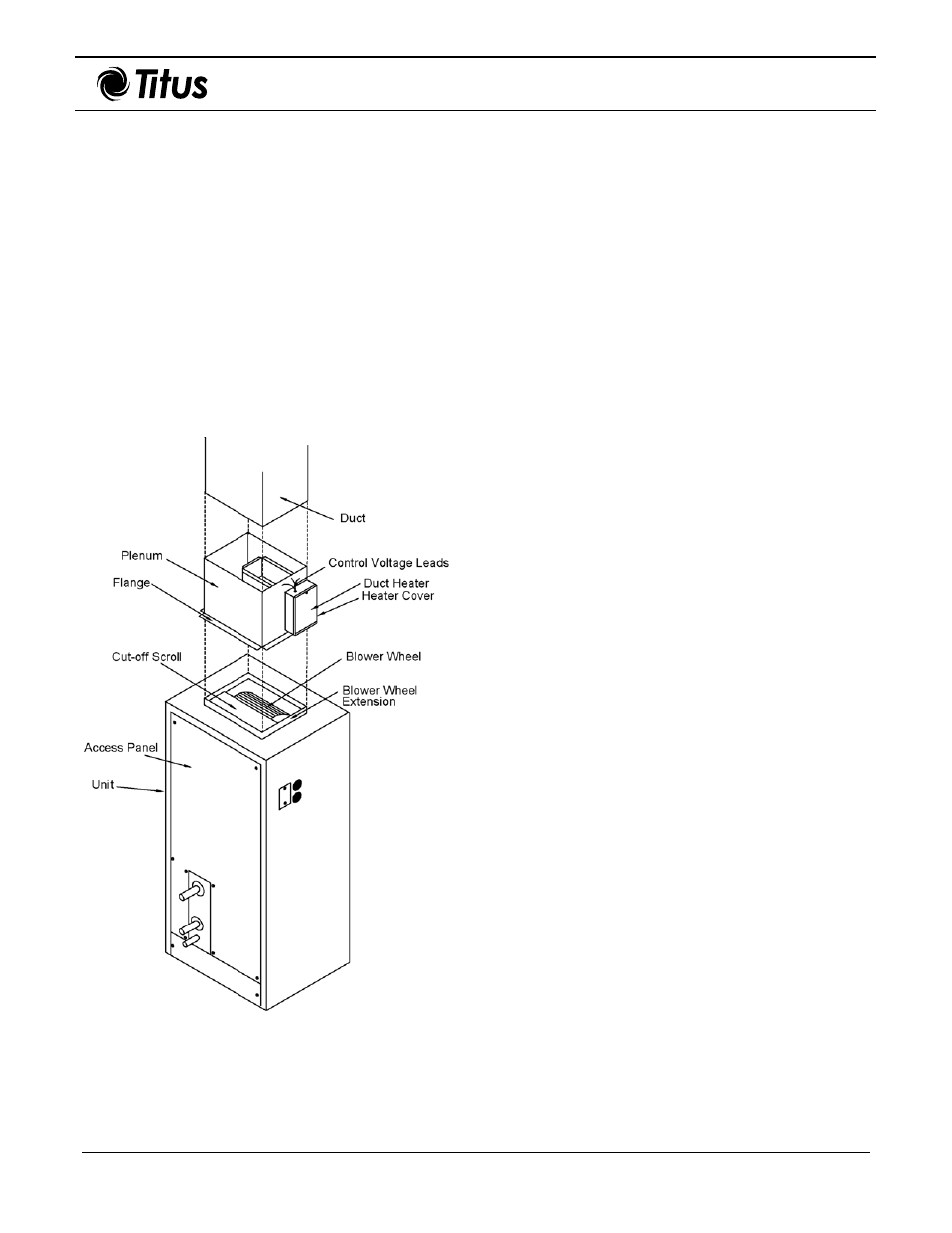

Electric Heater

Figure 8 shows electric heater components and their

placement and orientation to a VAB unit.

Preparation

Some items to consider prior to installing electric heat are

as follows:

•

Duct materials must be suitable for 250º F operation.

See NFPA 90A and 90B pamphlet.

Note: Electric heaters are incompatible with discharge

equipment.

•

Ensure ample room exists in the ductwork. Electric

heat must have at least 24 inches of straight duct

clearance before an elbow. If 24 inches are

unavailable, devices such as turning vanes or baffles

may be required.

Figure 8. VAB Unit with Electric Heater

Components

Installation

Use the following information to install electric heat on

VAB models.

1.

Position heater element section over the blower

wheel of the VAB unit.

Note: Heater baffle must align with blower cut-

off scroll. If necessary, rotate heater 180

degrees to align. This ensures proper blower

discharge of air over the heater elements.

2.

Attach electric heat plenum to VAB unit using #6 or

larger sheet metal screws.

Note: Ensure plenum securely attaches to VAB

unit only and not just to blower wheel

extension.

3.

Add insulation, if necessary, to outside of heater

plenum section.

Warning: Do not insulate duct heater.

Startup

Check the following items before startup.

•

Ensure all shipping bolts and screws are removed;

plus, ensure all other bolts and screws are tight.

•

Verify the voltage and phase on the unit nameplate,

and ensure it is the same as the motor wired.

•

Check the alignment of the sheaves (pulley wheels)

and ensure the setscrews are tight.

•

Check for proper rotation of the blower pulley.

•

Check motor phase and rotation.

−

Exchanging two of the three leads at the unit

junction box can reverse three-phase motor

rotation.

−

Exchanging leads inside the motor junction box

can reverse the rotation of single-phase motors.

Refer to the motor nameplate.

−

Not all installations require a starter (some

motors utilize a contactor).

•

Ensure all filters are installed.

•

Make sure all doors and panels are in place.

•

Check the amperage draw of the motor. The

amperage draw should not exceed the nameplate

amps shown on the motor serial plate.