Maintenance (cont) – Titus LSC IOM User Manual

Page 26

TU-LSC-IOM

Maintenance (Cont)

26

Hydronic Coil Cleaning Procedure

1. Disconnect all electrical power to the unit.

2. Don the appropriate personal protective equipment

(PPE).

3. Access both sides of the coil.

4. Use a soft brush to remove loose debris from both sides

of the coil.

5. Use a steam cleaning machine, starting from the top of

the coil and working downward. Clean the leaving air side

of the coil first, then the entering air side. Use a block-off to

prevent steam from blowing through the coil and into a dry

section of the unit.

6. Repeat step five as necessary. Confirm that the drain

line is open following completion of the cleaning process.

7. Allow the unit to dry thoroughly before putting the system

back into service.

8. Straighten any coil fins that may be damaged with a fin

rake.

9. Replace all panels and parts and restore electrical power

to the unit.

Winterizing the Coil

Make provisions to drain coils that are not in use, especially

when subjected to freezing temperatures. To drain the coil,

blow the coil out with compressed air. Next, fill and drain

the tubes with full-strength ethylene glycol several times.

Drain the coil as completely as possible.

Coil Freeze-up Damage!

Failure to properly drain and vent coils when not in

use during freezing temperatures may result in coil

freeze-up damage.

NOTICE

Replacing Motors

Motors are attached to the fan Blower with screws at the

rear of the motors. Fan wheels are attached with Allen

screws on the fan hubs. In most applications, it is

necessary to remove the fan blower to change out the

motor. The fan blower is easily removable, with screws on

the top and bottom edges of fan blower.

Heavy Object!

Support the Fan Blower when removing it from the unit.

Failure to properly support Fan Blowerd may result in minor

to moderate personal injury.

NOTICE

Work Instruction Steps

In general, replacement of a motor needs to be carried out

as follows:

1. Remove front panels of unit.

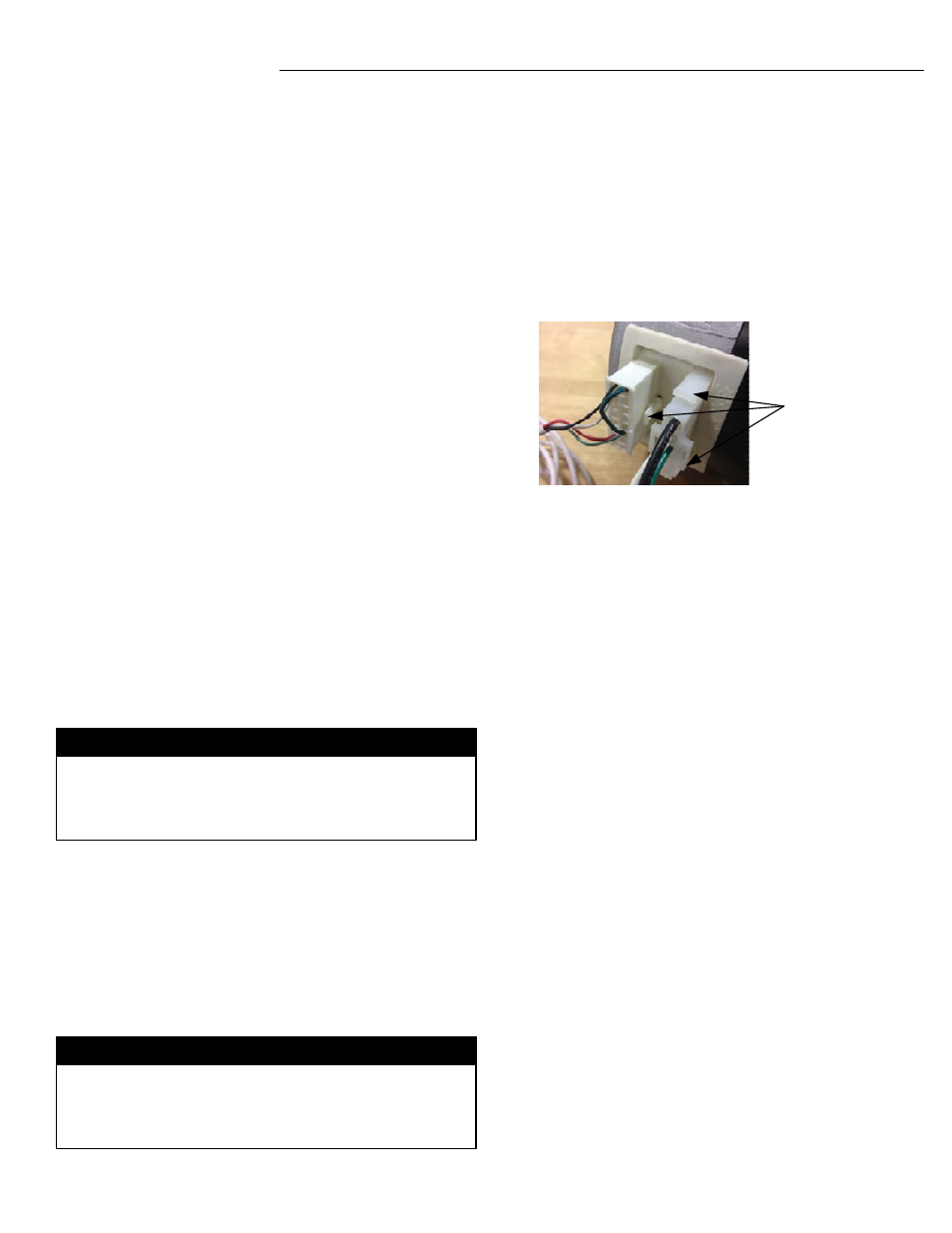

2.Free the motor and crossover harnesses from the fan

board, by unplugging the two electric multi plugs from the

motor.

3.Remove the fan housing with the motor and loosen fan

Allen screw on the shaft.

4.Unscrew the motor from the fan housing and remove.

5.Insert the replacement motor.

Periodic Maintenance Checklists

The following check list provides the recommended

maintenance schedule to keep the unit running efficiently.

Monthly Maintenance

1. Inspect unit air filters. Clean or replace if airflow is blocked

or if filters are dirty.

2.Check the drain pans s to be sure the pans are clean and

do not impede the potential condensate flow through the drain

line.

Annual Maintenance

Check and tighten all set screws, bolts, locking collars and

sheaves.

1. Inspect the unit liner clean or repair to provide unit

protection.

2.Inspect the fan wheel and housing for damage. Rotate the

fan wheel manually to be sure movement is not blocked by

obstructions.

3.Inspect the coil fins for excessive dirt or damage. Remove

dirt and straighten fins.

4.Clean and tighten all electrical connections.

5.Inspect the primary air damper and ensure that it rotates

freely from o to 100% open.

Depress Locking

tabs