Installation, Framing details location of fireplace, Hearth extension – Regency Excalibur EX90 Large Wood Fireplace (Canadian Edition) User Manual

Page 11

FPI FP90 Wood Fireplace

11

INST

ALLA

TION

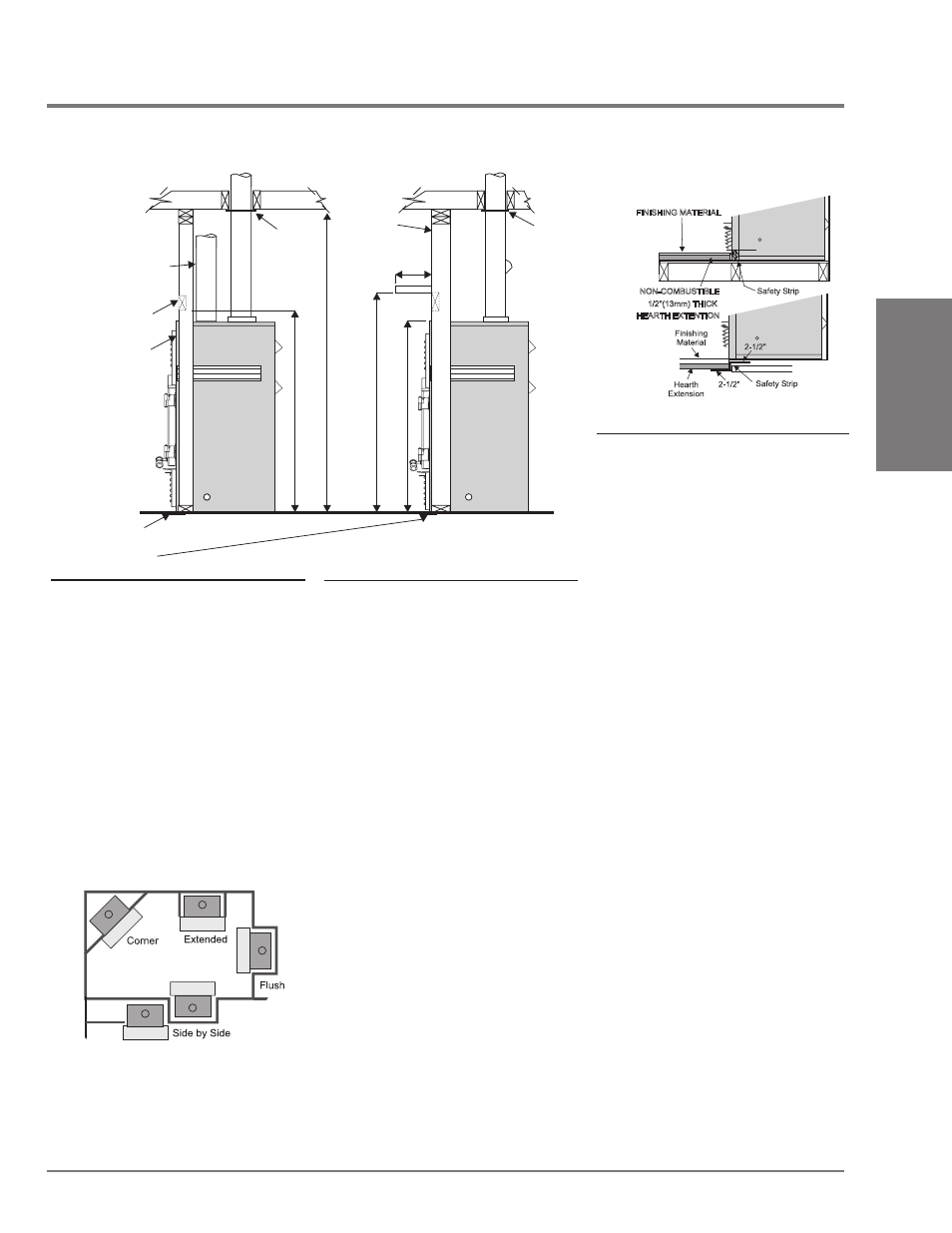

Fire Stop

FireStop

Straightrun

for 8"(203mm)

Hot Air Duct

Unit projects

out flush with

non-combustible

material

2 x 4 Framing

2 x 6 Framing

10"

2 x 6

Wall with a

2 x 4 Header

Stud

84"

(2137mm)

50-3/4"

(1289mm)

55-3/4"

(1416mm)

42-5/8"

(1083mm)

(254mm)

2 x 4

Stud Wall

5"(127mm)

wide sheet

metal strip under

unit and hearth

fraMinG details

location of

fireplace

1) Carefully select the proper location for heat

circulation, aesthetics, chimney obstructions

and clearance to side wall(s). With proper

pre-planning, a slight adjustment of a few

inches can save considerable time and

expense later during construction and

assembly.

2) Carefully consider the position of the fireplace

opening with respect to the location of

adjacent or nearby stairwells, bath or kitchen

exhaust fans and/or return air registers for

forced air furnaces/air conditioners that

could cause a smoking fireplace condition

if the house is tightly insulated.

3) Fireplace must be anchored to the framing

to prevent movement or rocking; use the

nailing strips which have been supplied.

The nailing strips are installed to the side

of the unit and to the front side of the 2 x 4

or 2 x 6.

1) Insert the metal safety strip, packaged

with the fireplace beneath the fireplace as

illustrated in Diagram 1 below. The safety

strip should be tacked down to prevent

possible shifting and should overlap for

continual coverage of the floor.

note: a safety strip is not required when the

fireplace rests on a non-combustible

surface.

note: install the hearth extension only

as illustrated.

The safety strip should extend 2 in. (51 mm)

in front and on the sides of the fireplace.

In the event a wooden support is used to

elevate the fireplace above the floor, a “Z”

type safety strip should be fabricated from

20 gauge galvanized sheet steel and used

to protect the front surface of the wood

support as well as the floor beneath the

hearth extension.

FINISHING MATERIAL

NON-COMBUSTIBLE

1/2"(13mm) THICK

HEARTH EXTENTION

(64mm)

(64mm)

diagram 1

note: the “Z” type safety strip is not

supplied by regency and must be

fabricated locally.

The proposed alternative is 4” (102mm) brick

with a C-factor of 1.25 over 1/8” (3mm) mineral

board with a k-factor of 0.29.

step (a): Use formula above to convert

specification to R-value.

R = 1/k x T = 1/0.84 x .75 = 0.893.

step (b): Calculate R of proposed system.

4” brick of C = 1.25, therefore

Rbrick = 1/C = 1/1.25 = 0.80

1/8” mineral board of k = 0.29,

therefore Rmin.bd. = 1/0.29 x

0.125 = 0.431

Total R = Rbrick + Rmineral board

= 0.8 + 0.431 = 1.231.

step (c): Compare proposed system R of

1.231 to specified R of 0.893.

Since proposed system R is

greater than required, the system

is acceptable.

definitions

Thermal Conductance:

C

= Btu = W

(hr)(ft2)(oF) (m2))(k)

Thermal Conductivity:

k =(Btu)(inch) = W = Btu

(hr)(ft3)(oF) (m)(k) (hr)(ft)(oF)

Thermal Resistance:

R = (ft2)(hr)(oF) = (m2)(k)

Btu

W

installation

HeartH eXtension

note: Hearth must have 1/2" (13mm) Millboard

under finish material with minimum "k" factor

of 20.07. When unit is raised 4" (102mm), the

thermal floor protection is not required. If you

plan to raise the fireplace and hearth extension,

build the platform assembly then position

fireplace and hearth extension on top. If you

are not raising the unit, check that you will have

sufficient clearance under the bottom louver

for your finishing material on top of the hearth

extension, i.e. tiles, concrete board, etc.

How to determine

if alternate floor

protection Materials are

acceptable

The specified floor protector should be 1/2”

(13mm) thick material with a k-factor of 20.07.