Nitrogen purge (non-standard service), Payload contamination control, Payload electromagnetic environment – Orbital Minotaur I User Manual

Page 39

Minotaur I User’s Guide

Section 4.0 – Payload Environment

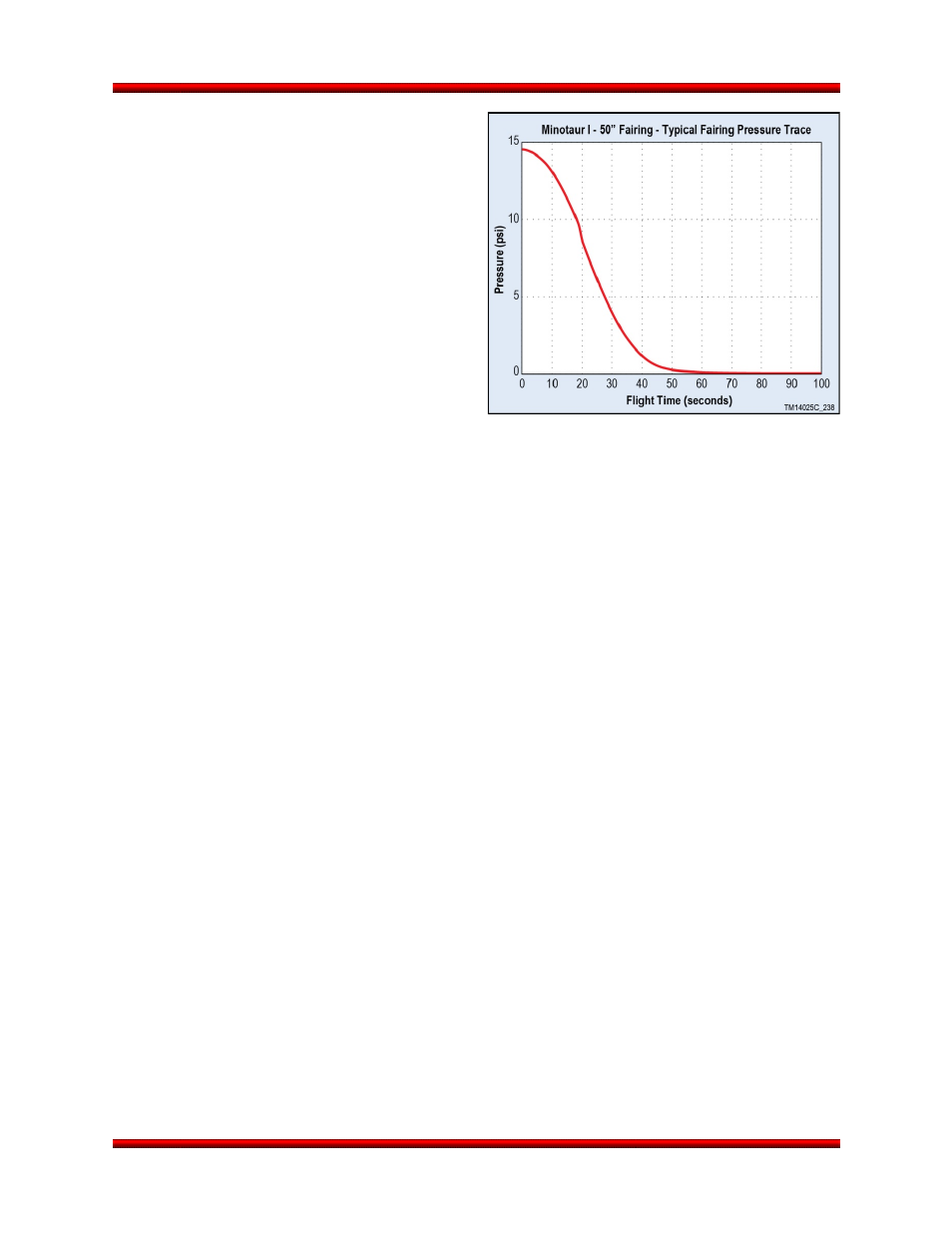

The fairing peak vent rate is typically less than 0.6

psi/sec. Fairing deployment will be initiated at a

time in flight that the maximum dynamic pressure

is less than 0.01 psf or the maximum free

molecular heating rate is less than 1135 W/m

2

(0.1

BTU/ft

2

/sec), as required by the payload.

4.6.3. Nitrogen Purge (non-standard service)

If required for spot cooling of a payload

component, Orbital will provide GN

2

flow to

localized regions in the fairing as a non-standard

service. This option is discussed in more detail in

Section 8.3.

4.7. Payload Contamination Control

All payload integration procedures, and Orbital’s

contamination control program have been

designed to minimize the payload’s exposure to contamination from the time the payload arrives at the

payload processing facility through orbit insertion and separation. The payload is fully encapsulated within

the fairing at the payload processing facility, assuring the payload environment stays clean in a Class

100,000 environment. Launch vehicle assemblies that affect cleanliness within the encapsulated payload

volume include the fairing, avionics assembly, Stage 4 assembly, and 3/4 Interstage. These assemblies

are cleaned such that there is no particulate or non-particulate matter visible to the normal unaided eye

when inspected from 2 to 4 feet under 50 ft-candle incident light (Visibly Clean Level II). After

encapsulation, the fairing envelope is either sealed or maintained with a positive pressure, Class 100,000

(ISO 8) continuous purge of conditioned air.

If required, the payload can be provided with enhanced contamination control as an option, providing a

Class 10,000 (ISO 7) environment, low outgassing, and Visibly Clean Plus Ultraviolet cleanliness. With

the enhanced contamination control option, the Orbital-supplied elements will be cleaned and controlled

to support a Class 10,000 clean room environment, as defined in ISO 14644-1 clean room standards

(ISO 7). This includes limiting volatile hydrocarbons to maintain hydrocarbon content at less than 15 ppm.

Also with the enhanced contamination control option, the ECU continuously purges the fairing volume

with clean filtered air and maintains humidity between 30 to 60 percent. Orbital’s ECU incorporates a

HEPA filter unit to provide ISO 7 (Class 10,000) air. Orbital monitors the supply air for particulate matter

via a probe installed upstream of the fairing inlet duct prior to connecting the air source to the payload

fairing.

4.8. Payload Electromagnetic Environment

The payload Electromagnetic Environment (EME) results from two categories of emitters: Minotaur I

onboard antennas and Range radar. All power, control and signal lines inside the payload fairing are

shielded and properly terminated to minimize the potential for Electromagnetic Interference (EMI). The

Minotaur I payload fairing is Radio Frequency (RF) opaque, which shields the payload from most external

RF signals while the payload is encapsulated. Details of the analysis can be provided upon request.

Figure 4.6.2-1. Typical Minotaur I Fairing

Pressure Profile

Release 3.0

March 2014

26