Str46spvg — maintenance (trowel) – Multiquip STR46SPVG User Manual

Page 32

STR46SPVG • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #2 (07/09/07) — PAGE 32

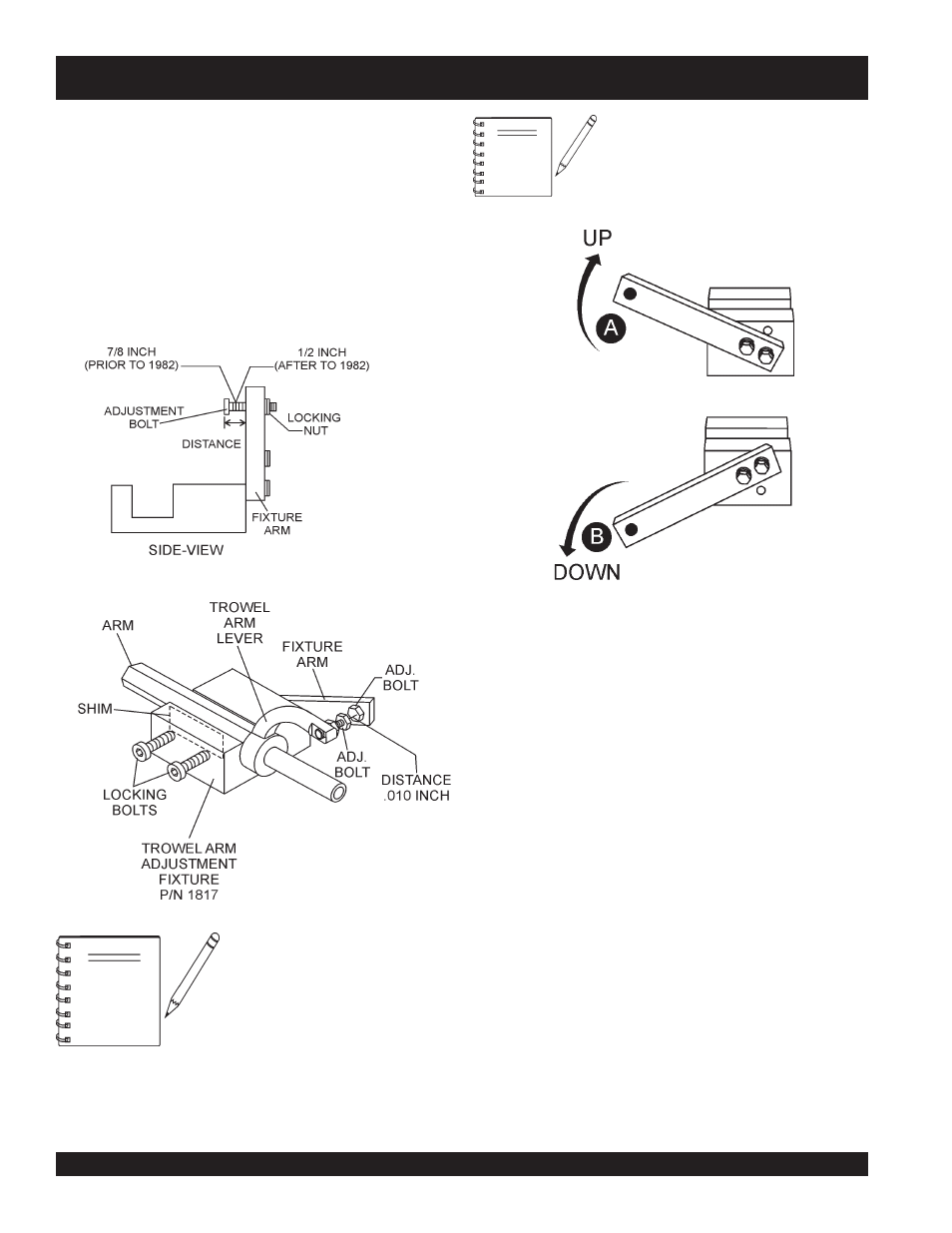

Trowel Arm Adjustment

Shown in Figure 28 is the adjustment fixture with a trowel arm

inserted. As each trowel arm is locked into the fixture, the

arm bolt is adjusted to where it contacts a stop on the fixture.

This will consistently adjust all of the trowel arms, keeping

the finisher as flat and evenly pitched as possible.

1. Locate the trowel arm adjustment tool P/N 9177.

2. Ensure the fixture arm is in the proper position (up or

down) for your trowel arm rotation as shown in Figure 29.

Figure 28. Trowel Arm

Adjustment Tool

STR46SPVG — MAINTENANCE (TROWEL)

The distance from the end of the

adjusting bolt and the fixture arm

must be 1/2".

Arms with CLOCK-WISE blade rotation use

the fixture arm in the UP position (A in Figure

39). Arms with COUNTER CLOCK-WISE

blade rotation use the fixture with the fixture

arm in the DOWN position. (B in Figure 29)

NOTE

Figure 29. Trowel Arm Adjustment Setup

3. Un-screw the locking bolts on the adjustment tool, and

place the trowel arm into the adjustment fixture channel

as shown in Figure 28. A

thin shim may be required to

cover the blade holes on the trowel arm. Make sure to

align the trowel adjustment bolt with the fixture adjust-

ment bolt.

4. Adjust the bolt "distance" shown in Figure 28 to match

one of the arms. The other arms will be adjusted to match

this distance.

5. Using an allen wrench, tighten the locking bolts on the

adjustment tool and securely lock the trowel arm in

place.

6. Loosen the locking nut on the trowel arm lever, then turn

the trowel arm adjusting bolt until it barely touches

(.010") the adjusting bolt on the fixture.

7. After the correct adjustment has been made, tighten lock

nut on trowel arm lever to lock in place.

8. Loosen locking bolts on adjustment fixture, and remove

trowel arm from fixture.

9. Repeat steps 2-8 for the remaining trowel arms.

NOTE