Str46spvg — maintenance (trowel) – Multiquip STR46SPVG User Manual

Page 31

STR46SPVG • RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #2 (07/09/07) — PAGE 31

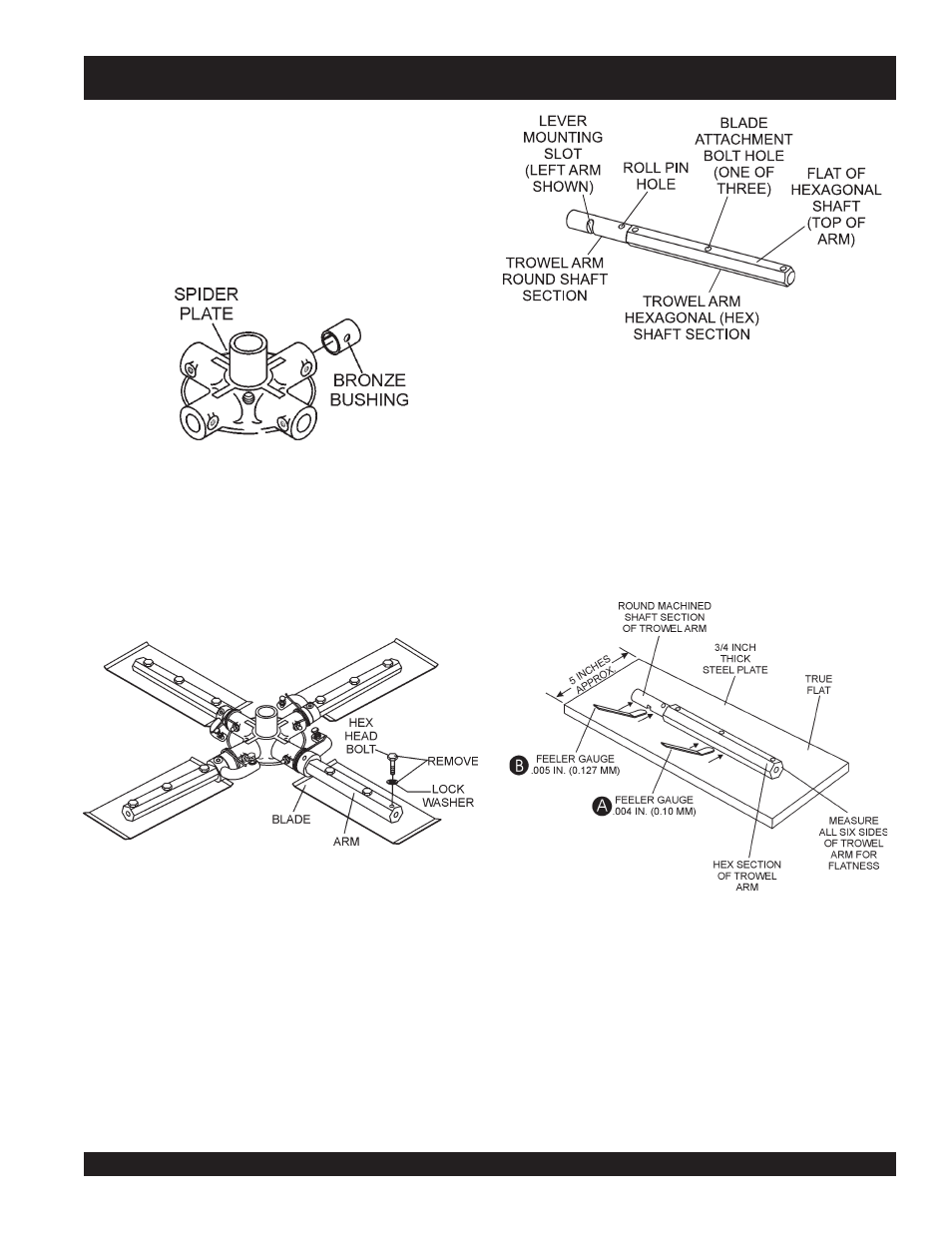

Trowel Arm Flatness Test

1. Using a piece of 3/4 inch thick steel plate or any surface which

is

true

and

flat

, check all

six sides

of each trowel arm for

flatness.

2. Check each of the six sides of the trowel arm (hex section).

A feeler gauge of .004" (0.10 mm) should not pass between

the flat of the trowel arm and the test surface along its length

on the test surface (Figure 46, A) .

Figure 27. Trowel Arm Flatness Test

3. Should the trowel arm inserts (bronze bushing ) come out

with the trowel arm, remove the bushing from the trowel arm

and set aside in a safe place. If the bushing is retained inside

the spider plate, carefully remove the bushing.

4. Examine the bronze trowel arm bushing insert (Figure 24),

clean if necessary. Replace bushing if out-of-round or worn.

Figure 24. Bronze Bushings

Trowel Blade Removal

1. Remove the trowel blades from the trowel arm by removing

the three hex head bolts (Figure 25) from the trowel arm. Set

blades aside.

Figure 25. Trowel Blades

2.

Wire brush

any build-up of concrete from all six sides of the

trowel arm. Repeat this for the remaining three arms.

STR46SPVG — MAINTENANCE (TROWEL)

Checking Trowel Arm Straightness

Trowel arms can be damaged by rough handling, (such as

dropping the trowel on the pad), or by striking exposed

plumbing, forms, or rebar while in operation. A bent trowel

arm will not allow the trowel to operate in a smooth fluid

rotation. If bent trowel arms are suspect, check for flatness

as follows, refer to Figures 26 and 27.

Figure 26. Typical Trowel Arm

3. Next, check the clearance between the round shaft and

the test surface as one of the flat hex sections of the arm

rests on the test surface. Rotate the arm to each of the

flat hex sections and check the clearance of the round

shaft. Use a feeler gauge of .005" (0.127 mm). Each

section should have the

same clearance between the

round of the trowel arm shaft and the test surface (Figure

27, B) .