Maintenance – Multiquip WSHE_A_SERIES User Manual

Page 39

WSHe/a vibraTory TruSS Screed • operaTion manual — rev. #0 (05/22/12) — page 39

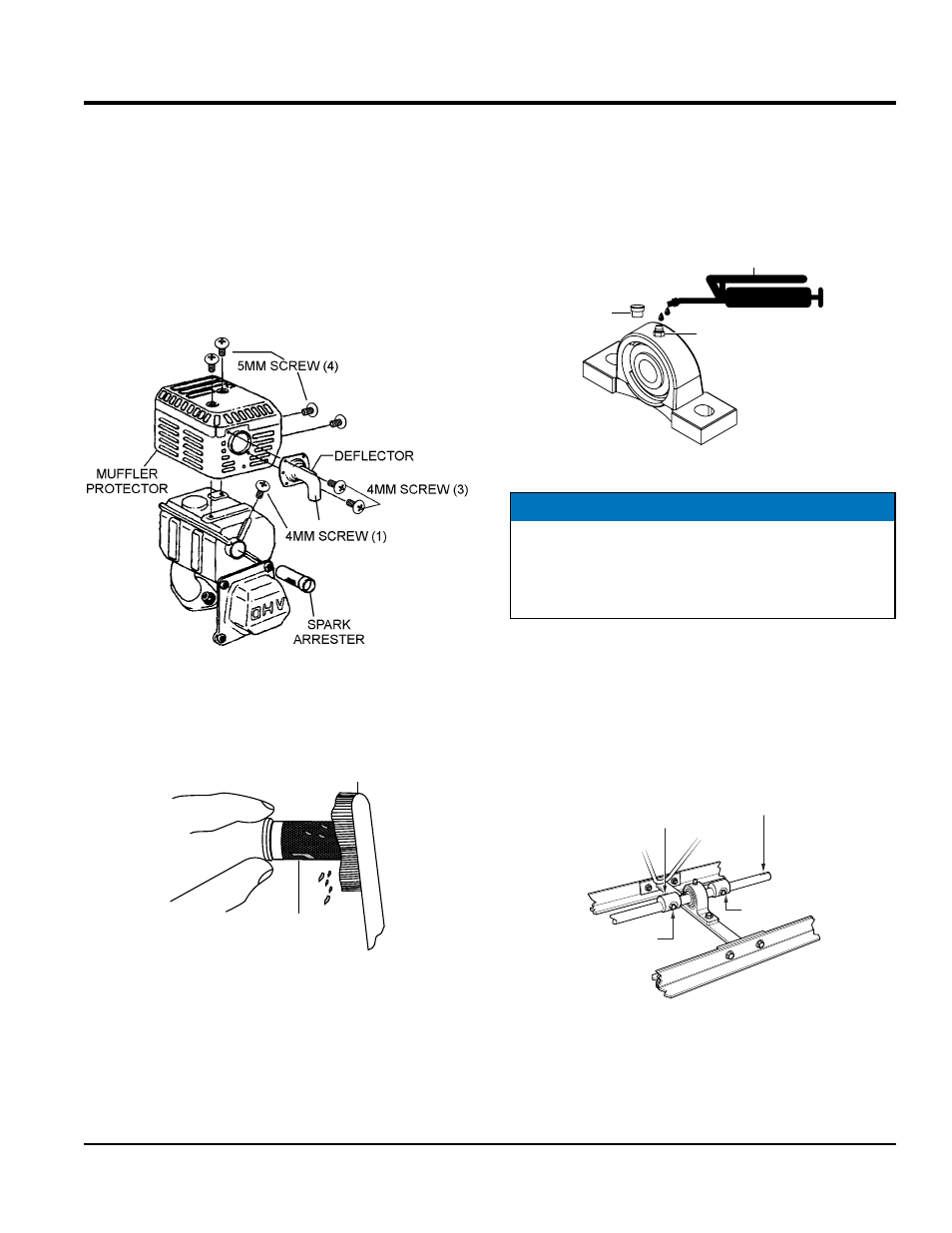

SparK arreSTer cleaning

Clean the spark arrester every 6 months or 100 hours.

1. Remove the 4 mm screw (3) from the exhaust deflector,

then remove the deflector. See Figure 32

2. Remove the 5 mm screw (4) from the muffler protector,

then remove the muffler protector.

3. Remove the 4 mm screw from the spark arrestor, then

remove the spark arrester.

Figure 32. Spark Arrester Removal

4. Carefully remove carbon deposits from the spark

arrester screen (Figure 33) with a wire brush.

Figure 33. Cleaning The Spark Arrester

5. If the spark arrester is damaged and has breaks or

holes, replace with a new one.

6. Reinstall the spark arrester and muffler protector in

reverse order of disassembly.

SPARK

ARRESTER

SCREEN

WIRE

BRUSH

Maintenance

SparK arreSTer cleaning

Each truss section has a set of pillow block bearings

(Figure 34) that will require lubrication. Lubricate the

grease fitting for each bearing every 40 hours of operation

using any grade lithium base grease

Figure 34. Bearing Maintenance

eccenTric SHaFT WeigHTS orienTaTion

Orientation of the eccentric shaft weights (Figure 35)

must be aligned so that the fat side of the weight is in line

(parallel) with the drive shaft key way.

For proper vibration of the shaft, all eccentric weights must

be aligned identically.

Figure 35. Eccentric Shaft Weight Orientation

GREASE

FITTING

GREASE

GUN

CAP

NOTICE

Failure to keep bearings lubricated (greased) will

cause rotation of eccentric drive shaft to stiffen. To

prevent contamination of the bearing, always insert the

protective cap onto the bearing grease fitting.

FAT SIDE

KEY WAY

ECCENTRIC WEIGHT

ECCENTRIC WEIGHT