Inspection – Multiquip WSHE_A_SERIES User Manual

Page 25

WSHe/a vibraTory TruSS Screed • operaTion manual — rev. #0 (05/22/12) — page 25

inSpectiOn

inspection Screed

1. Read all safety instructions at the beginning of manual.

2. Clean the entire screed, removing dirt and concrete

debris from the truss screed sections.

3. Make sure that the all bolts are secure and will not

vibrate loose.

4. Check for loose set screws on all shaft couplers.

5. Check jam nuts on top pipe to ensue that they are tight

against the top pipe coupler.

6. Check the oil and fuel levels of the engine (for engine-

driven screeds).

7. Check bearings for grease (bearings are pre-greased

from the manufacturer.

8. Check winch cables to make sure that they will not

become loose during the screed run.

9. Look over the forms to check for unevenness so that

the screed will not hang up.

inspection engine

1. Clean the engine, removing dirt and dust, particularly

the engine cooling air inlet, carburetor and air cleaner.

2. Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one as required.

3. Check carburetor for external dirt and dust. Clean with

dry compressed air.

4. Check engine mounting hardware fastening nuts and

bolts for tightness.

engine oil check

1. To check the engine oil level, place the screed on

secure level ground with the engine stopped.

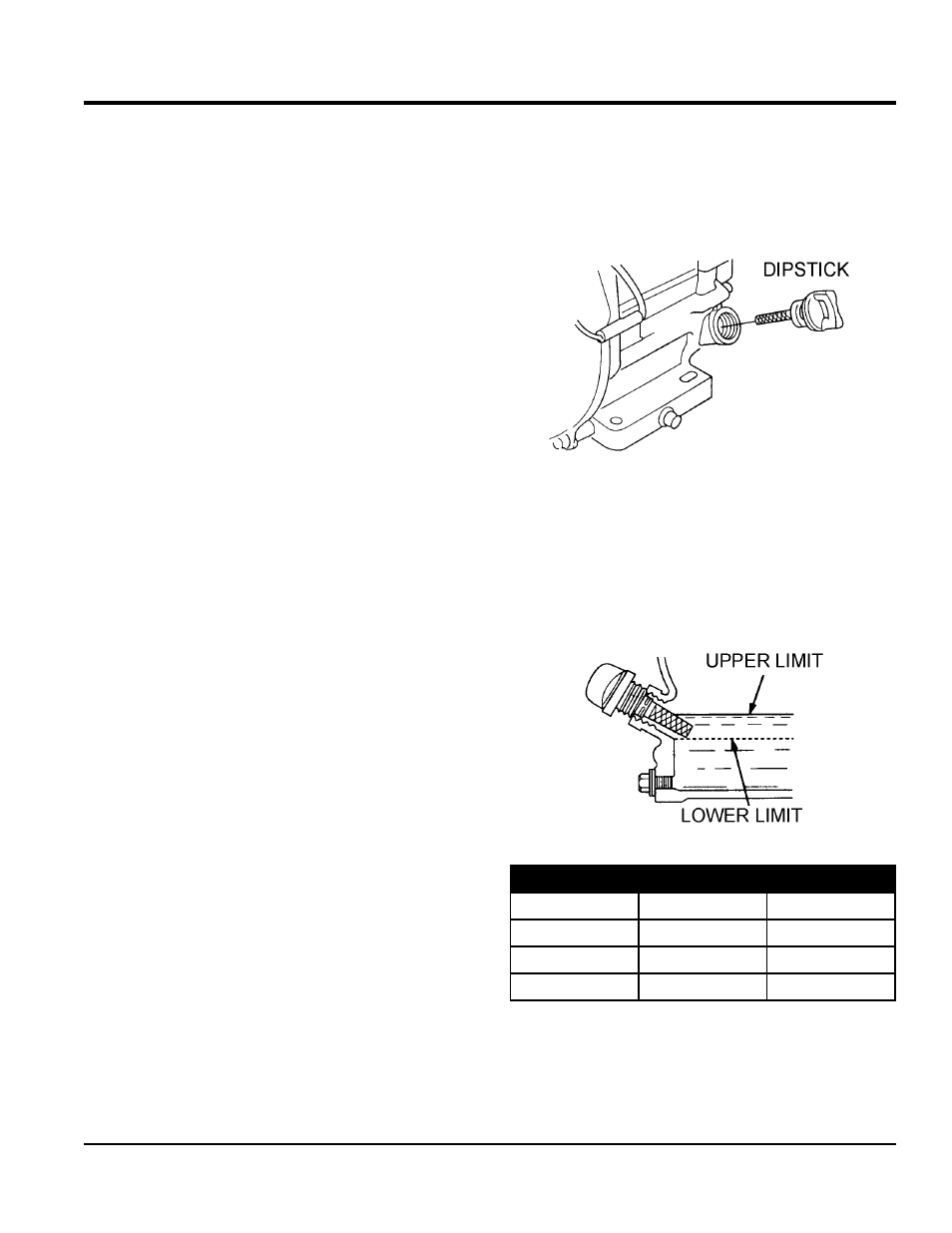

2. Remove the dipstick from the engine oil filler hole

(Figure 9) and wipe clean.

Figure 9. Engine Oil Dipstick Removal

3. Insert and remove the dipstick without screwing it into

the filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 10), fill to the edge of the

oil filler hole with the recommended oil type as listed

in Table 5. Reference Table 4 for maximum engine oil

capacity.

Figure 10. Engine Oil Dipstick (Oil Level)

Table 5. oil Type

Season

Temperature

oil Type

Summer

25°C or Higher

SAE 10W-30

Spring/Fall

25°C~10°C

SAE 10W-30/20

Winter

0°C or Lower

SAE 10W-10