General information, Heavy-duty steel construction, Steel truss design – Multiquip WSHE_A_SERIES User Manual

Page 19: Four different lengths, Standardization (air and engine driven), Screed blades, Bolt-on blade design, Air-powered screed, Engine driven screed

WSHe/a vibraTory TruSS Screed • operaTion manual — rev. #0 (05/22/12) — page 19

General infOrMatiOn

Multiquip vibratory truss screeds are used for leveling

pavement and industrial floors. They are available in air-

powered and engine-driven configurations. The vibratory

truss screeds provide dependable performance on job

after job. Its modular design allows the ability to configure

the screed by adding or removing sections as needed.

Figure 3 represents a typical vibratory screed application.

Heavy-duTy STeel conSTrucTion

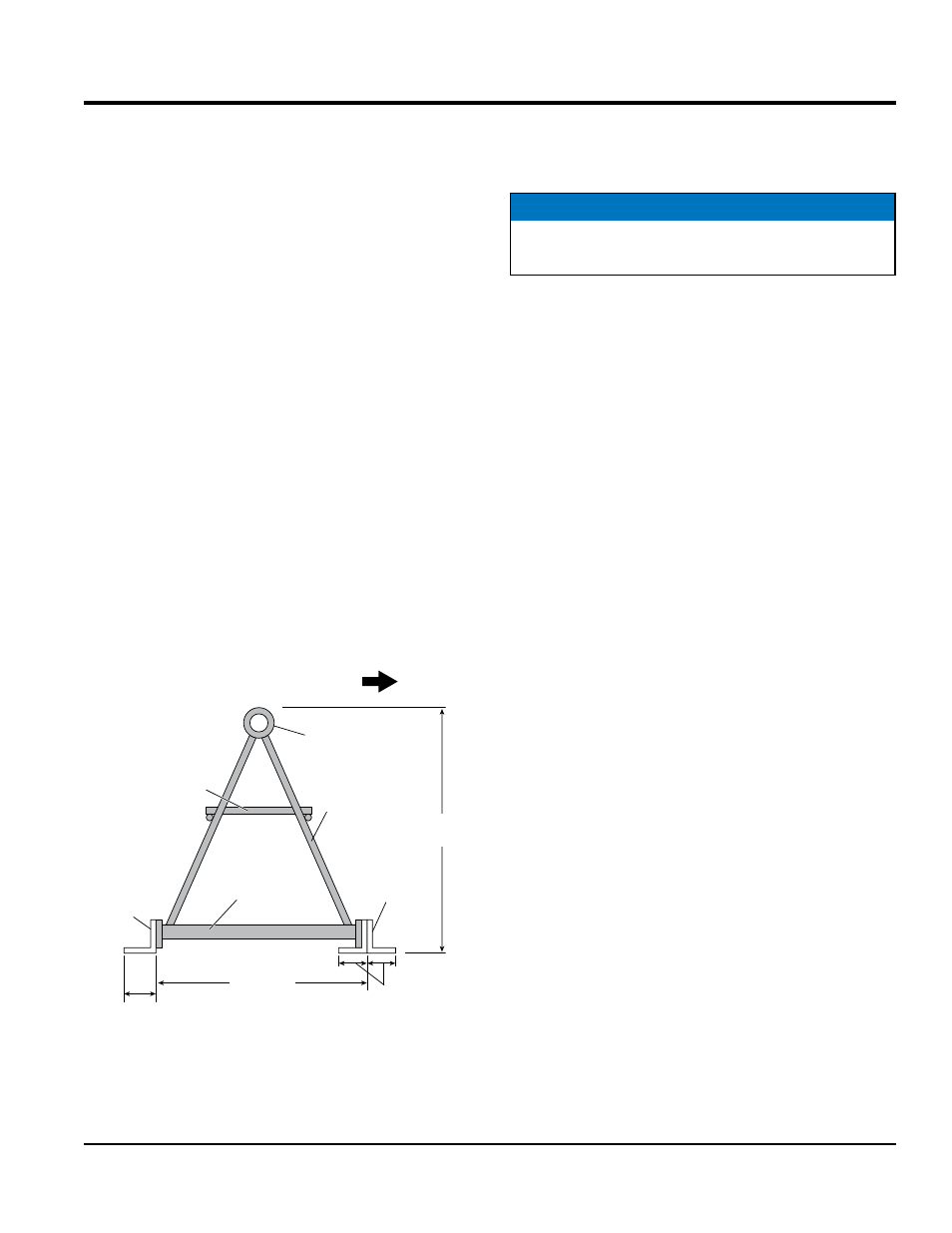

The Multiquip vibratory truss screed uses a triangular frame

design (Figure 4), built to take the abuse of rough handling

on a jobsite. Unlike the lightweight aluminum screed, the

steel screed will hold its precise shape better on long pours

and over a longer period of time. Additionally, the heavier

steel screed will stay down on the forms and will not ride up

during a pour. This vibratory screed weighs approximately

14 pounds per foot.

STeel TruSS deSign

The steel construction keeps the screed from riding up on

stiff concrete mix designs.

The vibratory truss screed features top pipe manufactured

from schedule 80 steel and features 16 TPI thread to

provide fine grade control should crowns or inverts be

required.

Figure 4. Screed Cross Section

SCHEDULE 80

TOP PIPE

3/8" TRUSS ROD

VIBRATION

DAMPENING

1/2" DIA.

TRUSS RODS

3/8" X 1-1/2"

BOTTOM TRUSS

SUPPORT

BULL FLOAT

BLADES

STRIKE-OFF

BLADES

2"

(51 MM)

16"

(406 MM)

3"

(76 MM)

12-3/8"

(314 MM)

DIRECTION

OF TRAVEL

ENGINE SIDE

OF SCREED

Four diFFerenT lengTHS

Multiquip Vibratory Screeds come in four lengths: 2-1/2 ft.,

5 ft., 7-1/2 ft. and 10 ft. sections.

STandardizaTion (air and engine driven)

Multiquip uses the same frame for both the air and engine

driven screeds. The top pipe is drilled and tapped to allow

air connections for the air vibrators.

Screed bladeS

The screed blades are constructed of 10-gauge galvanized

steel for rust resistance and maximum durability. The front

blades consist of two 1-1/2" high x 2" wide angles. This

gives the screed blades 2-1/2 inches of concrete surcharge

and 4 inches of screed surface. The rear (bull float) blade is

a single blade 2-1/2" wide. A total of 7 inches of concrete

surface contact is provided by the screed.

bolT-on blade deSign

The WSHE/A vibratory truss screeds features a bolt-

on blade design to allow easy replacement of worn or

damaged blades.

air-poWered Screed

Air vibrators offer high frequency (up to 9500 vibrations per

minute at 60 PSI) for excellent consolidation of low slump

mixes. The screed is capable of striking off slabs up to 11

inches thick (performance may vary according to mix design

and job requirements).

The vibrators are placed on 30-inch centers and located

at both front and rear blades for uniform vibration. Air

consumption is approximately 4CFM for each vibrator at

60 PSI. Crowns/Inverts up to 1/4" per foot are attainable

without an optional kit.

engine driven Screed

The engine-driven screed has an eccentric shaft design

that produces 8,000 vibration cycle nodes per minute. It

is ideal for slab, bridge, and highway applications. The

engine-driven screed is powered by either a 9 HP or 11 HP

Honda engine. Engine kits are available factory installed on

5-foot truss sections for reduced setup time at the job site.

Winch options include manual or self-propelled models.

NOTICE

It is best to allow a minimum overhang past the forms

(6" to 12" is ideal).