Assembly – Multiquip WSHE_A_SERIES User Manual

Page 27

WSHe/a vibraTory TruSS Screed • operaTion manual — rev. #0 (05/22/12) — page 27

aSSeMbly

The illustrations referenced in this section describe how

to assemble the vibratory screed. Listed below are the

various assemblies that will have to be assembled. End

Handle Section

engine Section

Truss Frame Section

Hand Winch Section

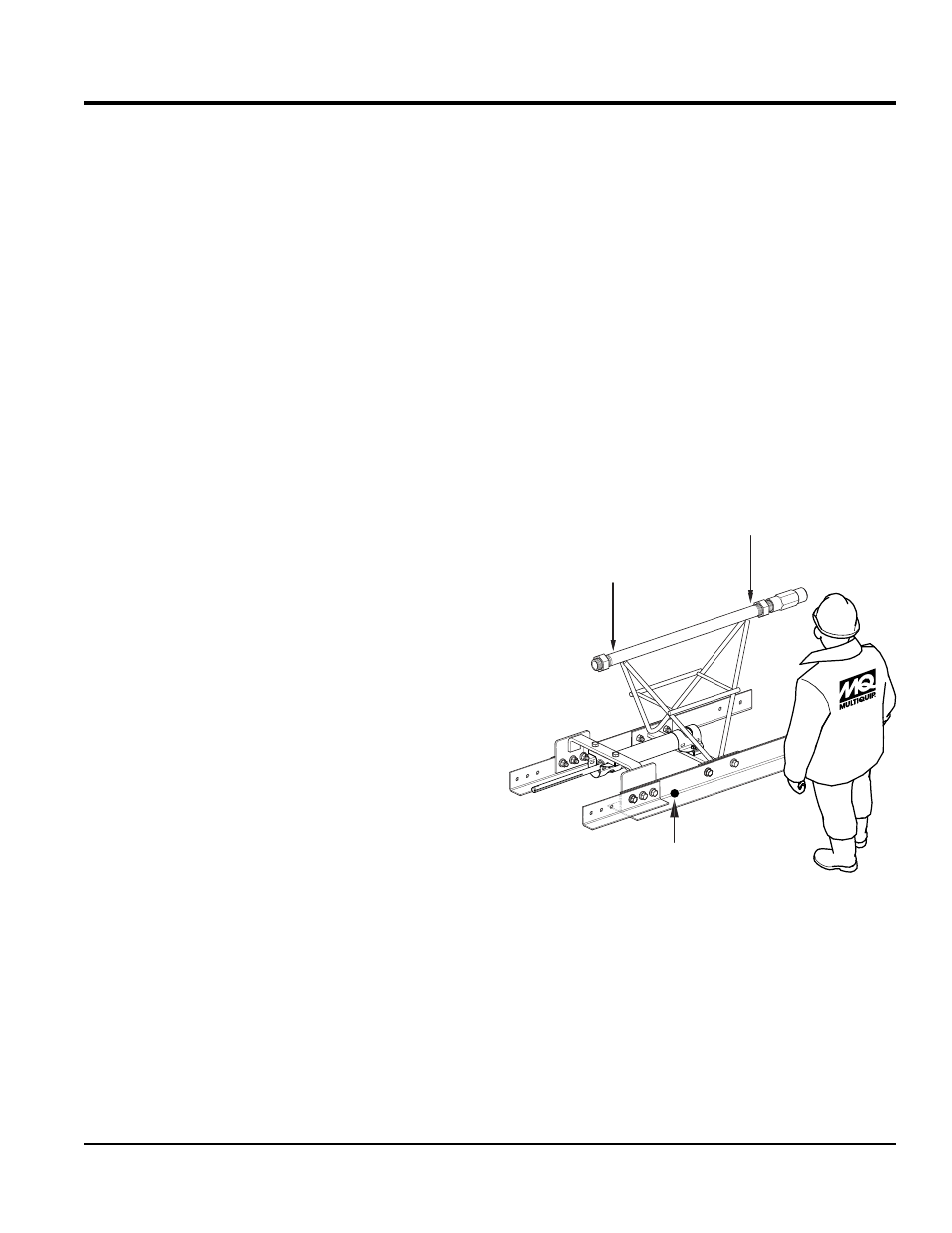

TruSS Screed Frame orienTaTion

Figure 14 shows how to determine the left, right, front and

rear of a screed frame truss section.

The right side of the screed truss frame will be stamped

with the letter "R" and the left side will be stamped with the

letter "L". In addition the front of the screed will have two

screed blades attached to the truss frame, while the rear

of the truss frame has only one bullfloat blade.

Figure 14. Screed Orientation

RIGHT

LEFT

FRONT

REAR

R

L

STAMPING

STAMPING

2 BLADES

aSSembly

alWayS assembled screed on a flat surface that is free of

debris and foreign objects. For best result place screed on

a flat platform during assembly. This will ensure flatness of

the screed blades when assembly is complete.

Things to remember during and after assembly:

• alWayS make sure eccentric drive shaft is properly

aligned.

• Make sure eccentric weights are installed correctly.

Reference Figure 35 for correct orientation.

• If eccentric weights are mismatched screed will not

vibrate properly.

• do noT overspeed, engine speed must not exceed

3600 RPM.

• never let concrete build on front blade. This condition

causes the screed to be stressed and make turning of

the winch handles difficult.

• do noT over vibrate concrete.

• Turn winch handles simultaneously to keep screed

even.