Inspection – Multiquip WSHE_A_SERIES User Manual

Page 26

page 26 — WSHe/a vibraTory TruSS Screed • operaTion manual — rev. #0 (05/22/12)

Fuel check

1. Visually inspect to see if fuel level is low. If fuel is low,

replenish with unleaded fuel.

2. When refueling, be sure to use a strainer for filtration.

do noT top-off fuel. Wipe up any spilled fuel

immediately.

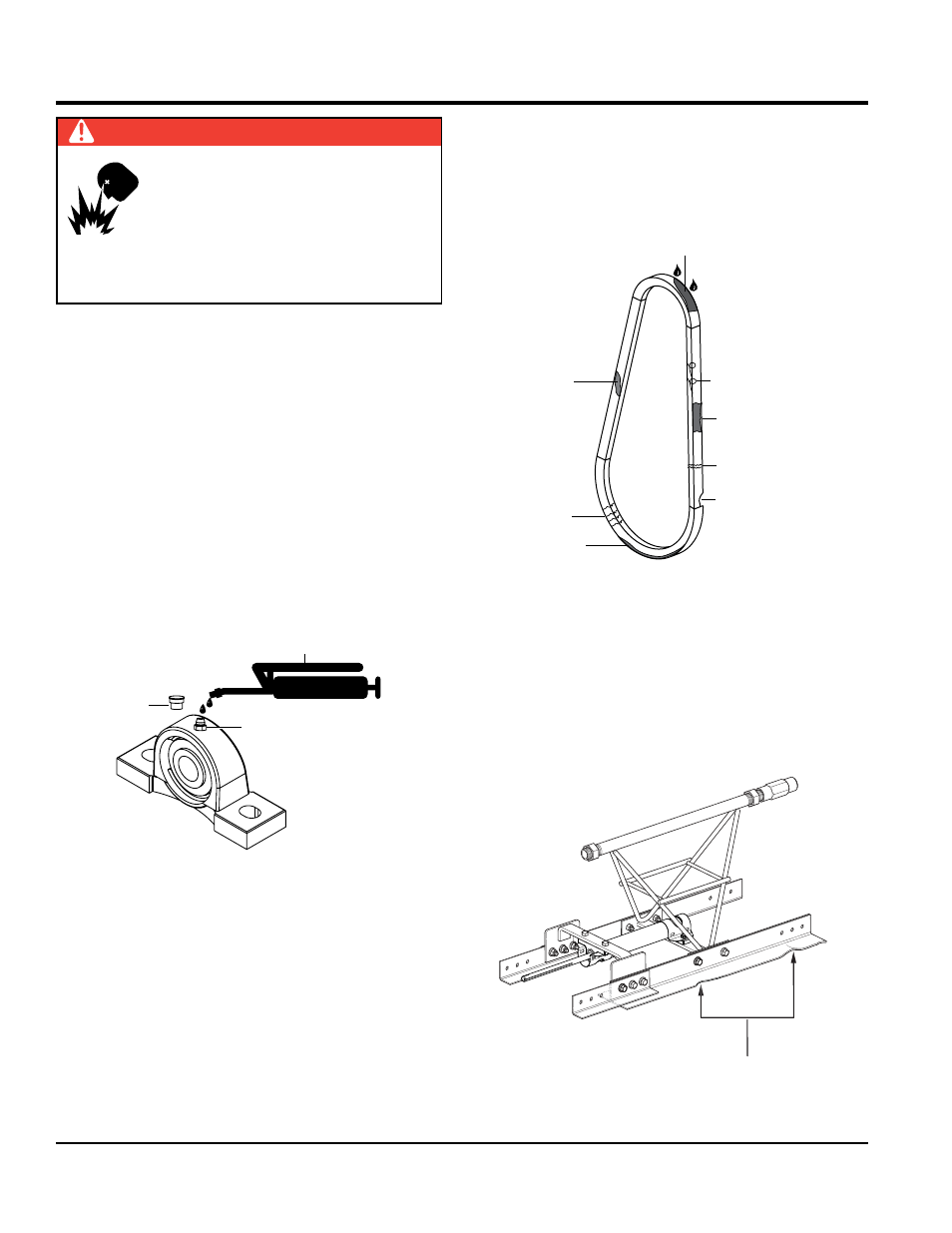

pillow block bearing lubrication

1. Each truss section has a set of pillow block bearings

(Figure 11) that will require lubrication. Always make

sure that the bearings are lubricated before each use

of the screed. See maintenance section in this manual

for bearing lubrication intervals..

Figure 11. Bearing Lubrication

danger

eXploSive Fuel!

Motor fuels are highly flammable and can

be dangerous if mishandled.

do noT

smoke while refueling.

do noT attempt

to refuel the trowel if the engine is hot! or

running.

GREASE

FITTING

GREASE

GUN

CAP

inSpectiOn

v-belt check

A worn or damaged V-belt (Figure 12) can adversely affect

the performance of the screed (gas driven). If a V-belt is

defective or worn simply replace the V-belt as outlined in

the maintenance section of this manual.

Figure 12. V-Belt Check

v-belt guard check

Check for damage, loose or missing hardware.

blade check

Check for worn or damaged blades (Figure 13). Check to

see if one blade is worn out while the others look new.

Replace any worn blades.

Figure 13. Blade Inspection

GLAZED

OIL SOAKED

BROKEN

CORD FAILURE

CRACKS

MISSING RUBBER

SIDEWALL

WEAR

WORN BACK

COVER

R

L

DAMAGED AREAS