Components – Multiquip WSHE_A_SERIES User Manual

Page 21

WSHe/a vibraTory TruSS Screed • operaTion manual — rev. #0 (05/22/12) — page 21

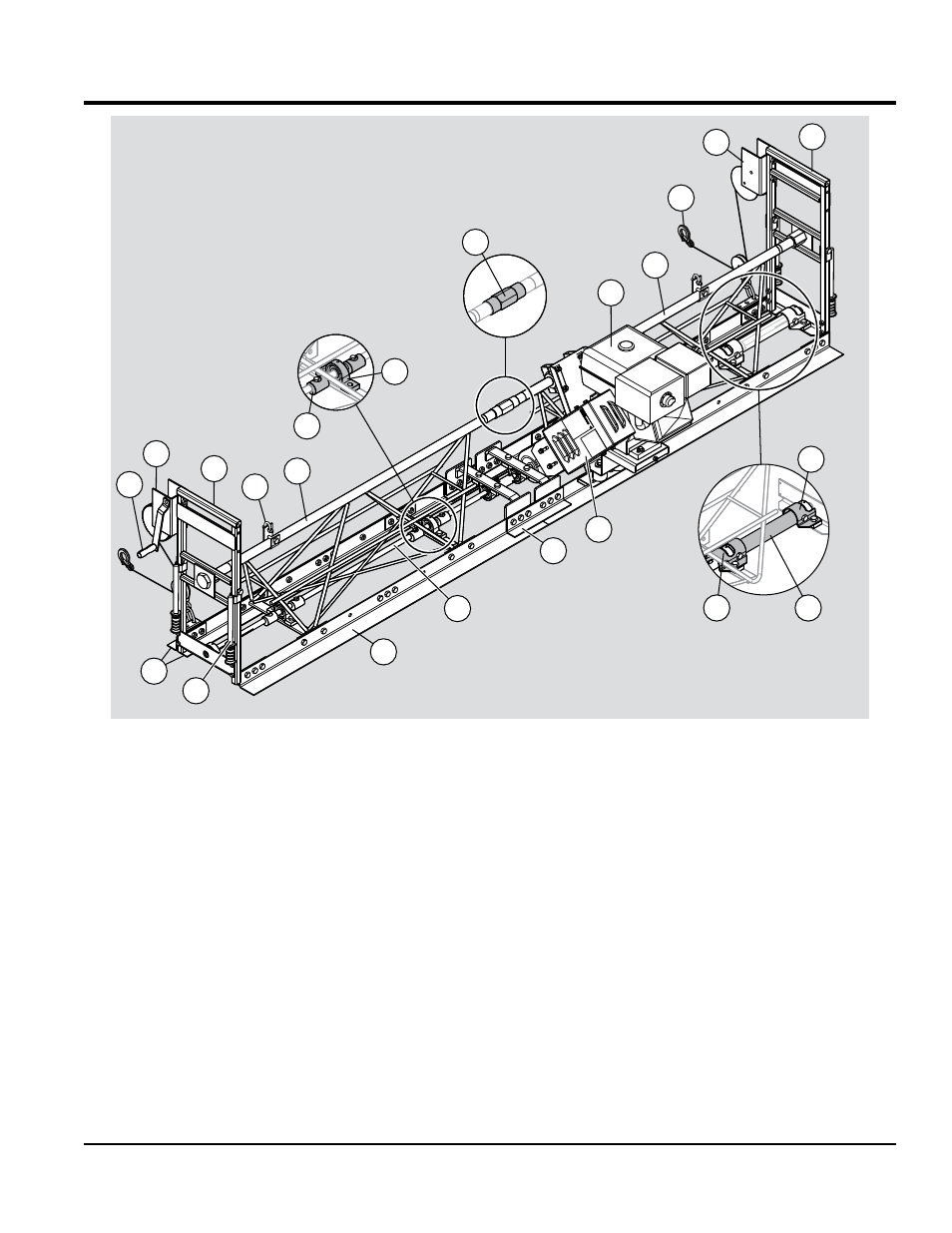

cOMpOnentS

1

2

14

13

15

13

15

17

18

16

5

6

9

3

3

12

8

7

4

10

11

11

Figure 5 and Figure 6 show the location of the basic

components of a 10-foot WSHE/A screed. The function of

each component is described below.

1.

rear (bull Float) blade — 2-1/2" high x 3" wide blade,

constructed of 10-gauge galvanized steel.

2.

Front blades — two 2-1/2" high x 2" wide blades,

constructed of 10-gauge galvanized steel.

3.

Truss Frame — Available in four lengths: 2-1/2 ft., 5 ft.,

7-1/2 ft. and 10 ft. (two 5 ft. sections illustrated above).

Each frame section features a heavy-duty schedule 80

top pipe for structural integrity.

4.

Turnbuckle — Connects two truss sections together.

Fine threads allow controlled adjustment for slight

crown or invert configurations.

5.

blade connector — Connects two blades together.

Bolt-on blade design allows for easy replacement of

worn or damaged blades.

6.

rotating eccentric Shaft — Produces over 8000

VPM, built of 3/4" diameter, high strength steel.

7.

pillow block bearings — Support rotating shaft.

8.

eccentric Weights — Bolted onto rotating shaft to

produce vibration.

9.

engine — Honda GX270 or GX340 engine drives the

rotating shaft.

10.

guard Tube — Covers the rotating shaft to prevent

equipment damage and operator injury.

11.

Tube mounts — Secure guard tubes to the truss frame.

12.

belt guard — Covers the rotating V-belt to prevent

operator injury.

Figure 5. WSHE Components