Maintenance – Multiquip MVH150VD2 User Manual

Page 21

MVH150VD2 PLATE COMPACTOR • OPERATION AND PARTS MANUAL — REV. #0 (10/10/08) — PAGE 21

Remove soil and clean the bottom of compaction

3.

plate.

Check hydraulic pump, piping and hose for any leakage.

4.

A loosened hydraulic hose can be a cause for leakage.

Check hydraulic hose connections with wrench applied

for tightness.

Check engine oil.

5.

ENGINE OIL REPLACEMENT

Replace engine oil, in fi rst 20 hours of operation and

1.

every 100 hours afterwards.

Oil may be drained more easily when it is warm after

2.

operation (For more details, see separate engine

Owner's Manual).

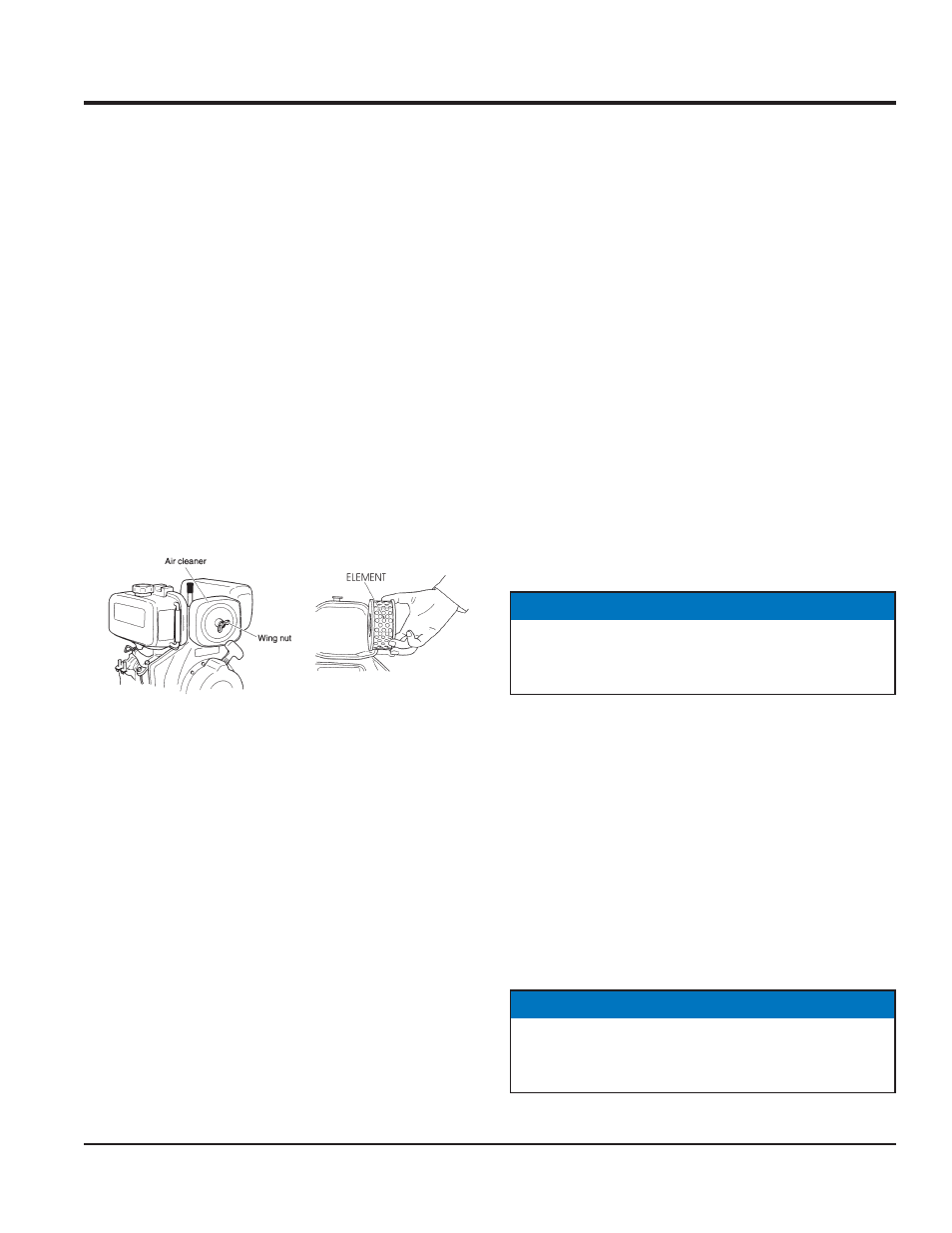

AIR FILTER

Remove the air cleaner cover and foam fi lter element

1.

as shown in Figure 18.

Air Filter

Figure 18.

Tap the paper fi lter element (Figure 18) several times on

2.

a hard surface to remove dirt, or blow compressed air

[not exceeding 30 psi (207 kPa, 2.1 kgf/cm2)] through

the fi lter element from the air cleaner case side.

Clean foam element in warm, soapy water or

3.

nonfl ammable solvent. Rinse and dry thoroughly. Dip

the element in clean engine oil and completely squeeze

out the excess oil from the element before installing.

CHECKING AND REPLACING V-BELT AND CLUTCH

After 200 hours of operation, remove the upper belt

1.

cover to check the V-belt tension. Tension is proper if

the belt bends about 10 mm when depressed strongly

with fi nger between shafts. Loose or worn V-belts

reduce power transmission effi ciency, causing weak

compaction and reducing the life of the belt itself.

MAINTENANCE

Replacing the V-belt

Remove the upper and lower belt covers. Engage an

offset wrench (13 mm) or the like to vibrator pulley (lower)

fastening bolt. Engage waste cloth or the like at midway

of V-belt on the left side and while pulling it back strongly,

rotate the offset wrench clockwise so that the V-belt will

come off.

Reinstalling the V-belt

Engage V-belt to lower vibrator pulley and push the V-belt

to left side of upper clutch. In the same manner as in

removal, rotate offset wrench clockwise so that the V-belt

goes back on.

Checking Clutch

Check the clutch simultaneously with V-belt checking. With

belt removed, visually check outer drum of the clutch for

seizure and "V" groove for wear or damage. Clean the "V"

groove as necessary. Regularly check the lining or shoe

for wear. If the shoe is worn, power transmission becomes

defi cient and slipping will result.

VIBRATOR OIL LEVEL CHECK

In every 300 hours of operation, with the machine

1.

positioned horizontally, remove vibrator oil level check

plug (Figure 6) off vibrator (14 mm wrench) and see

if oil is up to fi ller port. Be sure to clean area around

check hole to prevent dirt and dust from entering.

In every 300 hours of operation, replace oil (capacity

2.

400 cc). For draining oil through level check hole, have

the machine inclined with a sleeper or the like placed

under the compaction plate on opposite side.

*

Use engine oil 10W-30 for this lubrication.

NOTICE

Whenever the compactor's vibration becomes weak or

lost during normal operation, regardless of operation

hours, check the V-belt and clutch immediately.

NOTICE

Always clean the area around the vibrator oil level check

hole before removing oil check plug. This will prevent

dirt and debris from entering the system.