Maintenance and troubleshooting, Return to mk diamond for repair – MK Diamond MK-2000 User Manual

Page 36

MK-2000

Revision 03/05, Effective Date March 21, 2005

Page 36

MAINTENANCE AND TROUBLESHOOTING

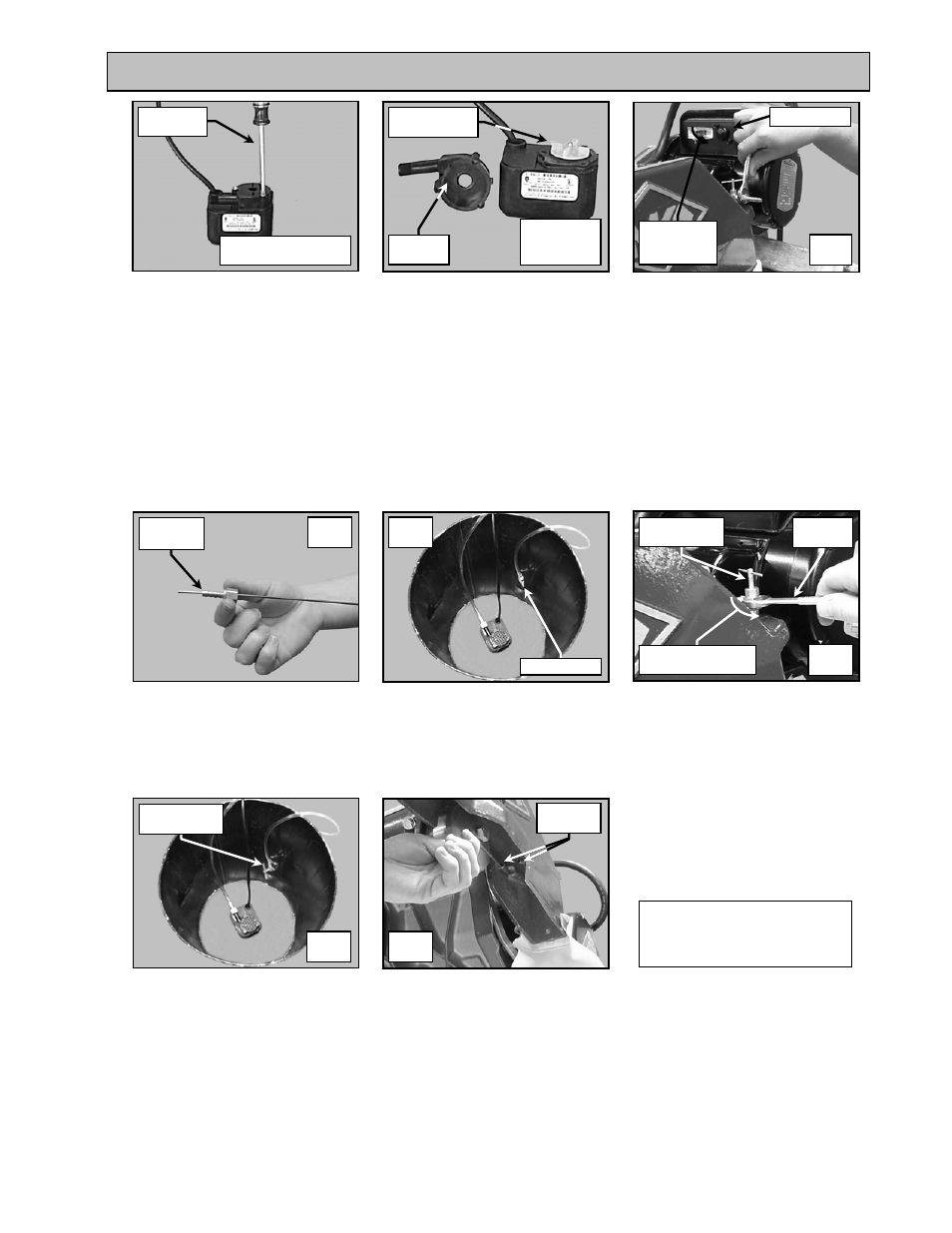

NOTE: “Rodding” cooling channels is performed by inserting a small wire rod through the cooling inlet on top

of the Blade Guard and directing the rod out through each of the cooling flow tubes located on the

underside of the Blade Guard. The cooling channels should be “rodded” until all ports are free of

foreign debris.

(J)

Check the Intake Fitting for

obstructions; Rod the Intake

Fitting using a stiff wire to

remove any obstructions

(I)

Using a 1/2-inch wrench,

remove the Intake Fitting from

the Cooling Flow Control Valve

(H)

Remove the Pump Casing and

check for restriction; check

Impeller damage

(G)

Remove the 3 Pump Casing

Retaining Screws

Check Impeller

for damage

Phillips

Screwdriver

Check for

restriction

If no damage

or restrictions,

go to Step I

Turn counter-

clockwise to

loosen

Go to

Step J

Intake Fitting

Once Screws removed

go to Step H

(M)

Attach the Flow Control Valve

to the Intake Fitting and check

flow (See Step C)

(N)

Rod Cooling Channels and

recheck flow; if after performing

Steps A to N flow still does not

exist, go to Step O

Rod

Channels

Rod Intake

Fitting

Go to

Step M

Turn counter-

clockwise to loosen

Cooling Flow

Control Valve

9/16- inch

Wrench

(L)

Using a 9/16-inch wrench,

remove the Flow Control Valve

from the Blade Guard

Go to

Step K

(K)

Install the Intake Fitting onto

the Cooling Transfer Tube and

check flow (See Step C)

Go to

Step L

Intake Fitting

Go to

Step N

Cooling Flow

Control Valve

Go to

Step O

Return to

MK Diamond

for Repair

(O)

Return to MK Diamond