3 design of the cables, 4 how to connect the shield, Wiring the installation backplane – Lenze E94AZPP User Manual

Page 53

Wiring the installation backplane

Wiring

Design of the cables

l

53

EDK94ZPP0364 DE/EN/FR/ES/IT 2.1

5.3.3

Design of the cables

ƒ

The cables used must comply with the approvals required for the location

(e.g. UL).

ƒ

It is imperative to comply with the regulations concerning minimum

cross−sections of PE conductors. The cross−section of the PE conductor

must be at least as large as the cross−section of the power connections.

ƒ

The effectiveness of a shielded cable is reached by:

–

Providing a good shield connection through large−surface shield

contact.

–

Using only braided shields with low shield resistance made of tin−plated

or nickel−plated copper braid.

–

Using braided shields with an overlap rate > 70 % and an overlap angle

of 90 °.

–

Keeping unshielded cable ends as short as possible.

Use system cables or shielded cables for these connections:

ƒ

External brake resistor (

, Mounting Instructions of the brake resistor)

The following connections need not be shielded:

ƒ

Mains

ƒ

DC bus

5.3.4

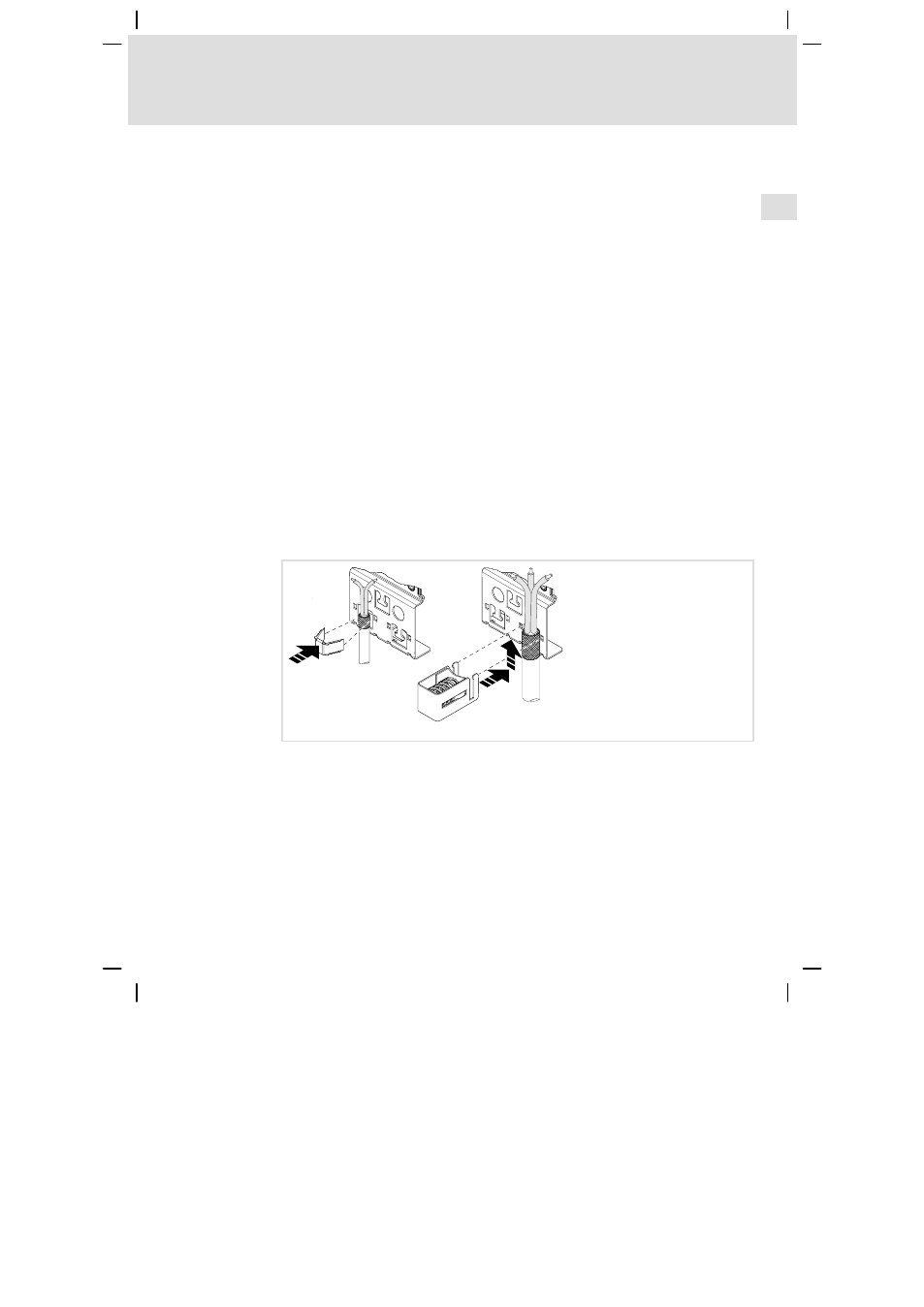

How to connect the shield

E94AZPS004

Fig. 5−5

Connect the shield to the shield sheet (graphics on the right: motor cable for device sizes

II and III)