Troubleshooting guide, Chapter 5 – Landoll 2510 Series In-Row Ripper User Manual

Page 31

5-1

Chapter 5

Troubleshooting Guide

The Troubleshooting Guide, shown below, is included to

help you quickly locate problems that can happen using

your 2510 Series In-Row Ripper. Follow all safety

precautions stated in the previous sections when making

any adjustments to your machine.

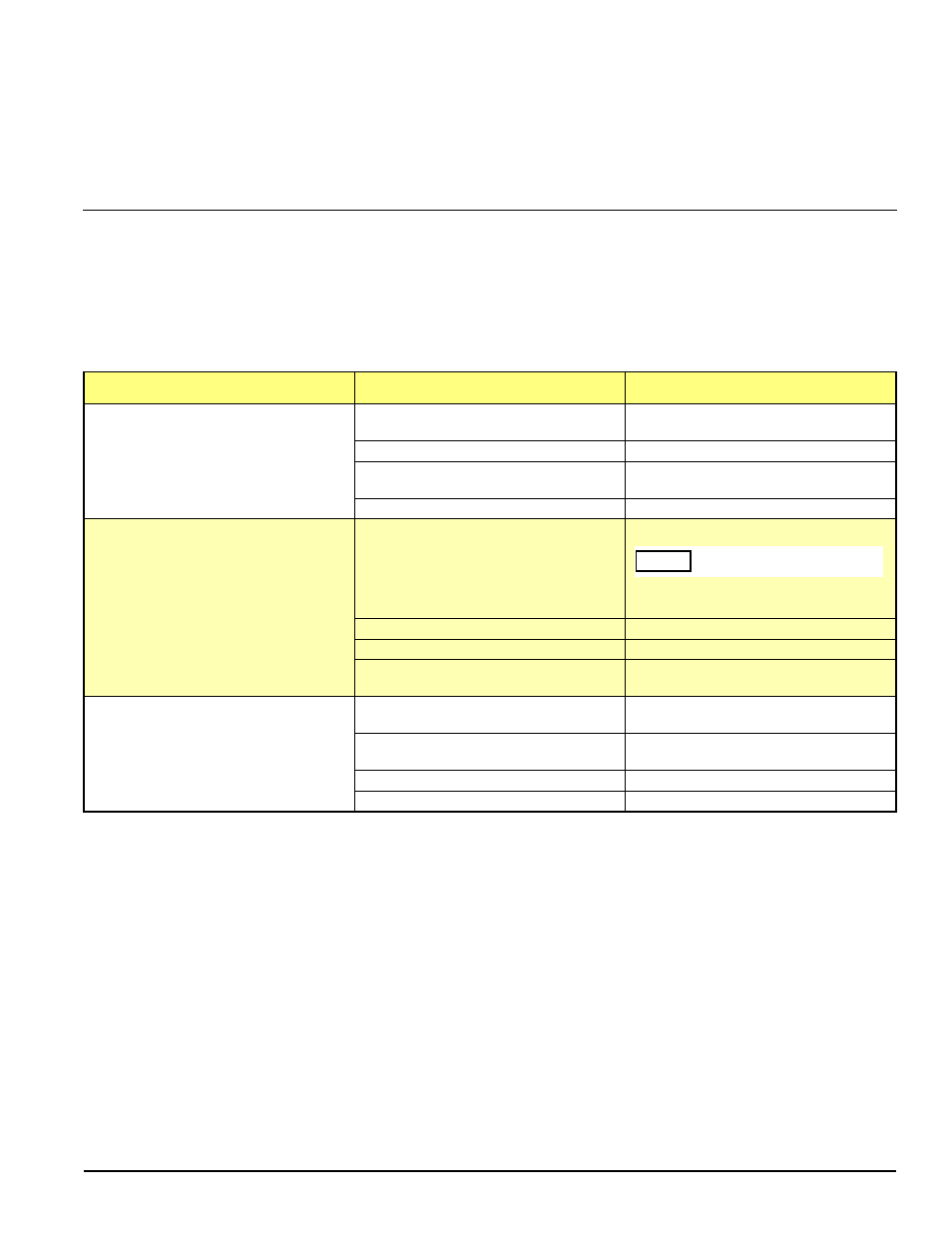

PROBLEM

PROBABLE CAUSE

SOLUTION

SPIKES DO NOT PENETRATE TO

DESIRED DEPTH

Coulters set too deep

Adjust coulters up, to just run in firm soil, to

cut residue.

Spikes worn back

Replaces spikes

Lower hitch arms in lower holes of pull

bracket

Move hitch arms to upper hole in pull

brackets.

Implement not level

Adjust top 3-point link.

UNIT BOUNCES OR NOT WORKING AT

UNIFORM DEPTH

Gauge wheels not set at correct depth

Adjust gauge wheels to correct depth.

NOTE

Gauge wheels, not the 3-point hitch,

should carry the load.

Gauge wheels not set at correct depth

Adjust all gauge wheels to same depth.

Tire pressure not equal

Inflate all tires to the same pressure.

Lower hitch arms not set to same height

Measure lower hitch arms and adjust to

uniform length.

RESIDUE HANGS ON SHANKS

Coulter not set deep enough

Adjust coulter down to run in firm soil, to

cut residue.

Gauge wheel too close to shank

Position gauge wheel on frame for

maximum clearance to shanks.

Coulter not aligned

Check coulter alignment on front bar.

Soil too wet causing hairpinning of residue

Let soil dry.