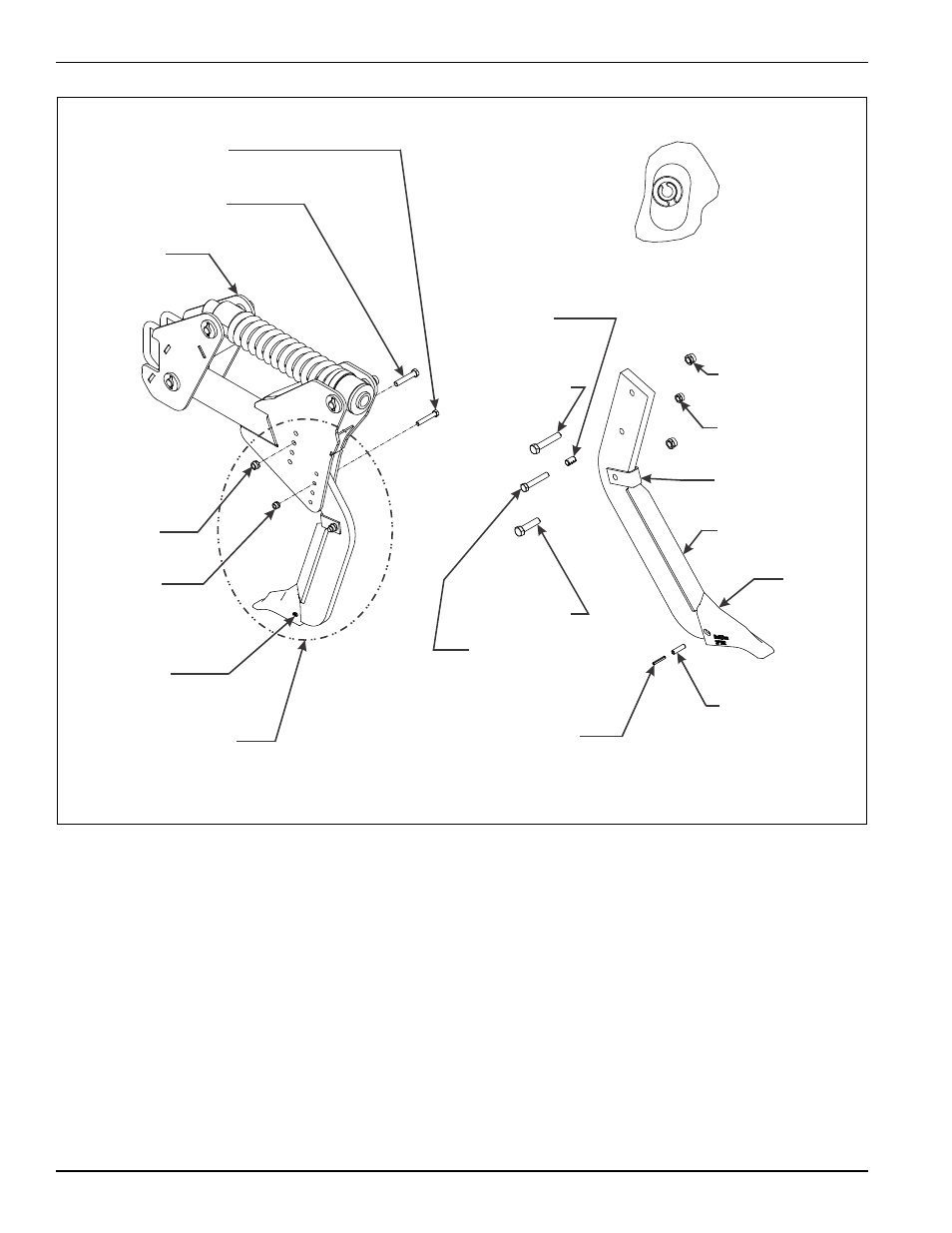

Figure 3-2: auto-reset clamp and shank assembly, Auto-reset clamp and shank assembly – Landoll 2510 Series In-Row Ripper User Manual

Page 18

3-4

F-729-0913 Edition

ASSEMBLY INSTRUCTIONS

Figure 3-2: Auto-Reset Clamp and Shank Assembly

Auto-Reset Clamp and Shank

Assembly

1.

The spring clamp weldments are already located on

the frame at the proper spacing.

2.

Attach wearstrip to straight leg shank using wearstrip

bracket, 3/4-10 x 3 hex head cap screw, and 3/4-10

hex lock nut(See Figure 3-2.)

3.

Attach steel point to straight leg shank using 1/2 x 2

and 5/16 x 2 spring slotted pins. Place pins with open

ends oriented opposite of each other.

4.

Attach top of shank point assembly to front of spring

clamp assembly using 3/4-10 x 4 hex head cap

screw and hex lock nut. Attach lower hole of shank

point assembly to rear of spring clamp assembly

using 5/8-11 x 3-3/4 hex head cap screw, connex

bushing, and 5/8-11 hex lock nut.

5.

Adjustment holes are provided in the spring clamp

weldment to compensate for varying ground

conditions.

5/8-11 X 3-3/4 HEX

HEAD CAP SCREW

3/4-10 X 4 HEX

HEAD CAP SCREW

SPRING CLAMP

ASSEMBLY

3/4-10 X HEX

LOCK NUT

5/8-11 HEX

LOCK NUT

SHANK POINT

ASSEMBLY

SEE DETAIL A

m179964 op

DETAIL A

3/4-10 HEX

LOCK NUT

5/8-11 HEX

LOCK NUT

WEARSTRIP

BRACKET

WEARSTRIP

1/2 X 2 SPRING

SLOTTED PIN

CONNEX

BUSHING

3/4-10 X 4

HEX HEAD

CAP SCREW

3/4-10 X 3

HEX HEAD

CAP SCREW

5/8-11 X 3-3/4

HEX HEAD

CAP SCREW

5/16 X 2 SPRING

SLOTTED PIN

STEEL

POINT

POINT PIN

PLACEMENT