Tires, Lubrication, Chain tension – Landoll SS/SSB/SSP/SSBP 8, 10, 12 Sure Stand Seeder User Manual

Page 55

MAINTENANCE

4-3

Tires

Recommended inflation pressure is a follows:

7.00/7.60-15 6 ply rating..........40 psi

9.5 L-15 6 ply rating..........32 psi

11 L-15 8 ply rating..........28 psi

Lubrication

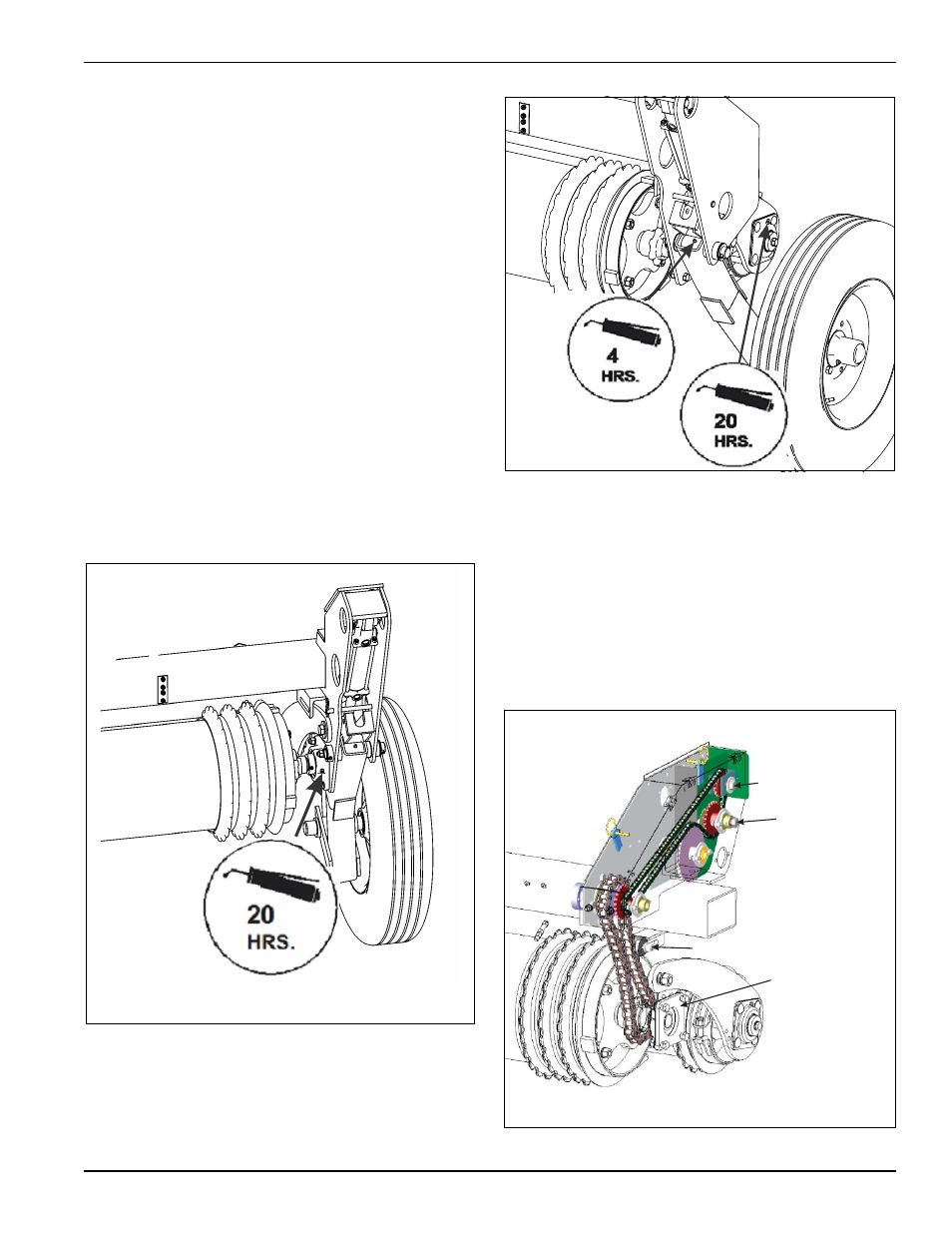

• All machines have a grease zerk on each bearing end

of the front and rear rollers. Pull type machines have a

zerk on each wheel arm pivot as well. See Figures 4-1

and 4-2.

• Oil roller chains periodically.

• Repack wheel bearings annually.

• Grease all bearings every 20 working hours.

• Grease wheel arms every 4 hours when machine in

constantly raised.

• When the machine is not used for some time, exposed

portions of the hydraulic cylinder rods must be cleaned

and covered with a thick coat of grease to prevent

corrosion, which will damage the seals.

Figure 4-1: Lube Points (1 of 2)

Figure 4-2: Lube Points (2 of 2)

Chain Tension

To adjust the transmission chain, first loosen the 5/8” idle

axle bolt and then use the clevis bolt to obtain about 1/8”

-1/4” sag. Re-tighten the axle bolt. Be careful not to

over-tighten this chain. See Figure 4-3.

Adjust the chain between the front roller and transmission

to have approximately 2” of total deflection. See

Figure 4-4.

Figure 4-3: Loosen Idle Bolt

Movable Idler

Idler Axle Bolt

Clevis Drawbolt

Front Roller