Tires, Wheel bearing maintenance, Lubrication – Landoll MCL/MCC/MCLS/MLCS/MCCS 1483, 1643, 1803 RIGID PULVI-MULCHER User Manual

Page 45: Hydraulic maintenance, Fasteners, Caution lubrication

MAINTENANCE

4-3

Tires

Recommended inflation pressure for the 9.5L X 15-6 Ply

tire is 30-32 PSI.

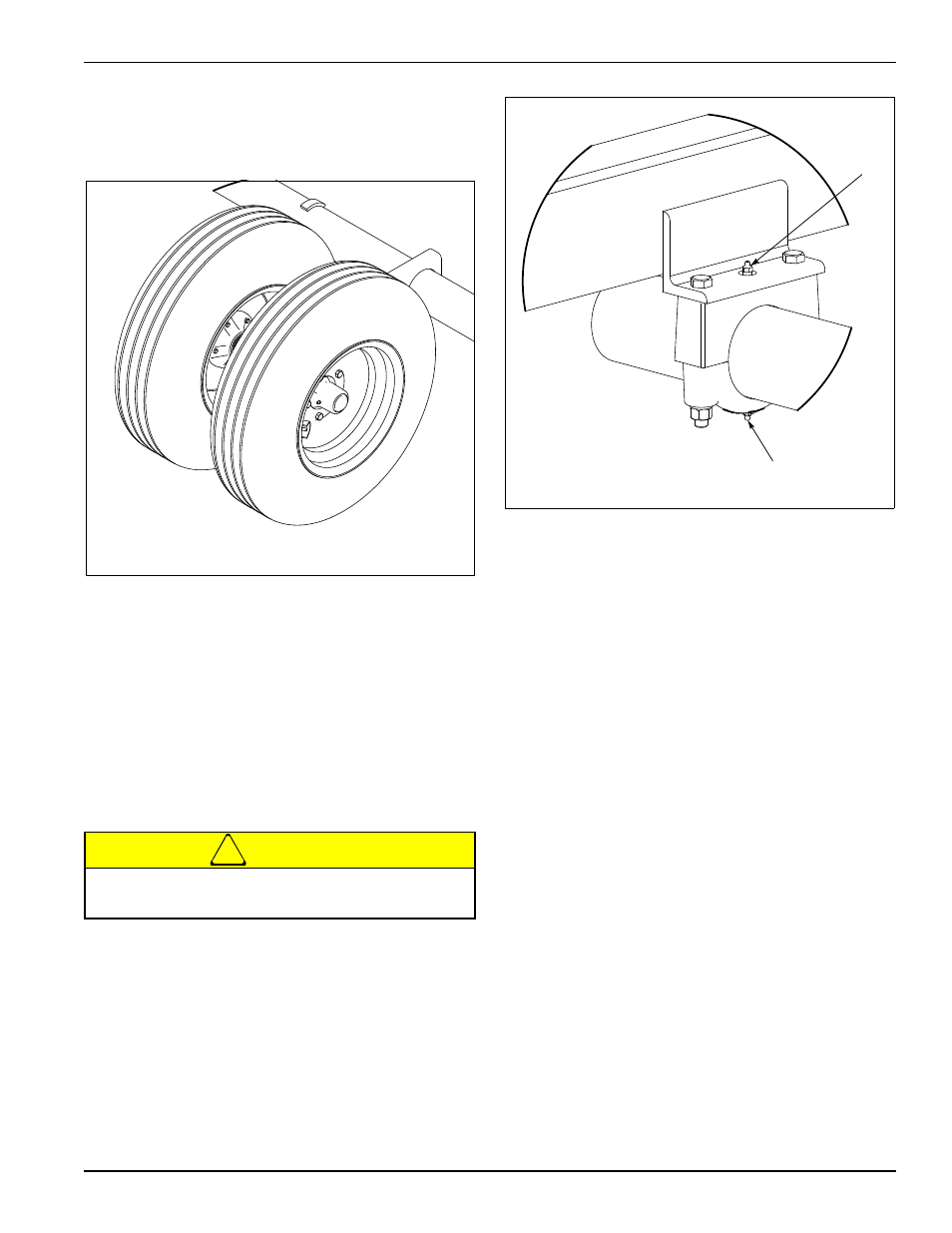

Figure 4-1 Wheel Hub

Wheel Bearing Maintenance

Wheel bearing maintenance should be performed at the

beginning of every season of use. Check the wheel

bearing for excessive end play. If needed, adjust or

replace them.

Lubricating Wheel Hub:

Grease Wheel Hubs every 40-60 hours.

Repack Wheel Hub bearings annually before each

season usage. See Figure 4-1.

CAUTION

Lubrication

Lubricate bearings with quality grease per recommended

lubrication frequency intervals indicated or if machine is

not used for an extended period. Greaseable

components are the same on each side.

Grease zerk fittings daily. Each of the four rockshaft

bearings has two fittings an upper and lower. See

Figure 4-2.

Figure 4-2 Rockshaft Bearings

Hydraulic Maintenance

1.

Check the tractor hydraulic fluid level per tractor

owners manual and after any leakage. Check fluid

level with cylinders in the retracted position.

2.

If a cylinder or valve leaks, disassemble the parts to

determine the cause of the leak. Any time a cylinder

is opened up, or whenever any seal replacement is

necessary, it is advisable to clean all parts and

replace all seals. Seal kits are available from your

Landoll dealer.

3.

Check all hydraulic hoses weekly. Look for binding or

cracking. Replace all worn or defective parts

immediately.

Fasteners

Before operating your Brillion machine, check all

hardware for tightness. Use the Tightening Torque Table

below as a guide. See Page 4-1.

After a few hours of use, check entire machine and

tighten any loose nuts or bolts. Daily or periodic checks

should be made thereafter.

When replacing bolts, be sure to use fasteners of equal

grade.

Over lubrication of these bearings can cause

premature bearing failure.

Grease

Daily

Grease

Daily