Warning – Bryant Series E/F 310AAV User Manual

Page 20

20

2” (51mm)

Street Elbow

A08551

Fig. 21

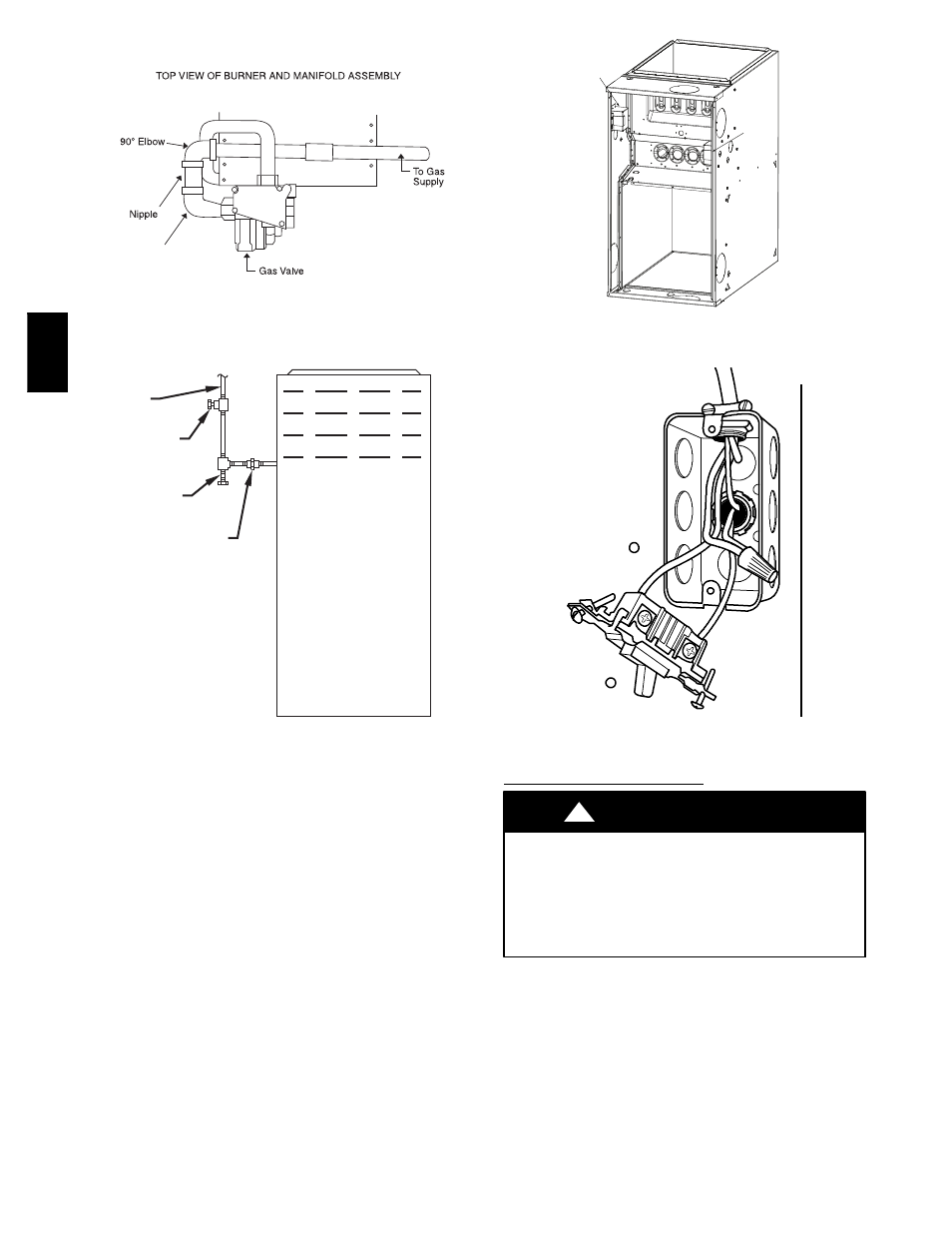

--- Burner and Manifold

UNION

SEDIMENT

TRAP

MANUAL

SHUTOFF

VALVE

(REQUIRED)

GAS

SUPPLY

A02035

Fig. 22

--- Typical Gas Pipe Arrangement

Piping should be pressure and leak tested in accordance with

NFGC, local, and national plumbing and gas codes before the

furnace has been connected. After all connections have been

made, purge lines and check for leakage at furnace prior to

operating furnace.

If pressure exceeds 0.5 psig (14--In. W.C.), gas supply pipe must

be disconnected from furnace and capped before and during

supply pipe pressure test. If test pressure is equal to or less than

0.5 psig (14--In. W.C.), turn off electric shutoff switch located on

furnace gas control valve and accessible manual equipment

shutoff valve before and during supply pipe pressure test. After

all connections have been made, purge lines and check for

leakage at furnace prior to operating furnace.

The gas supply pressure shall be within the maximum and

minimum inlet supply pressures marked on the rating plate with

the furnace burners ON and OFF.

Factory

Factory

Installed

Installed

Alternate

Alternate

Location

Location

A10291

Fig. 23

--- Relocating J--Box

A10141

Fig. 24

--- Field--Supplied Electrical Box on Furnace Casing

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Blower access panel door switch opens 115--v power to

control. No component operation can occur. Do not bypass

or close switch with panel removed.

!

WARNING

See Fig. 26 for field wiring diagram showing typical field 115--v

wiring. Check all factory and field electrical connections for

tightness.

310AA

V