Warning – Bryant Series E/F 310AAV User Manual

Page 12

12

APPROVED

COIL ASSEMBLY

OR

COIL BOX

FURNACE

SHEET METAL

PLENUM

FLOOR

OPENING

COMBUSTIBLE

FLOORING

A08556

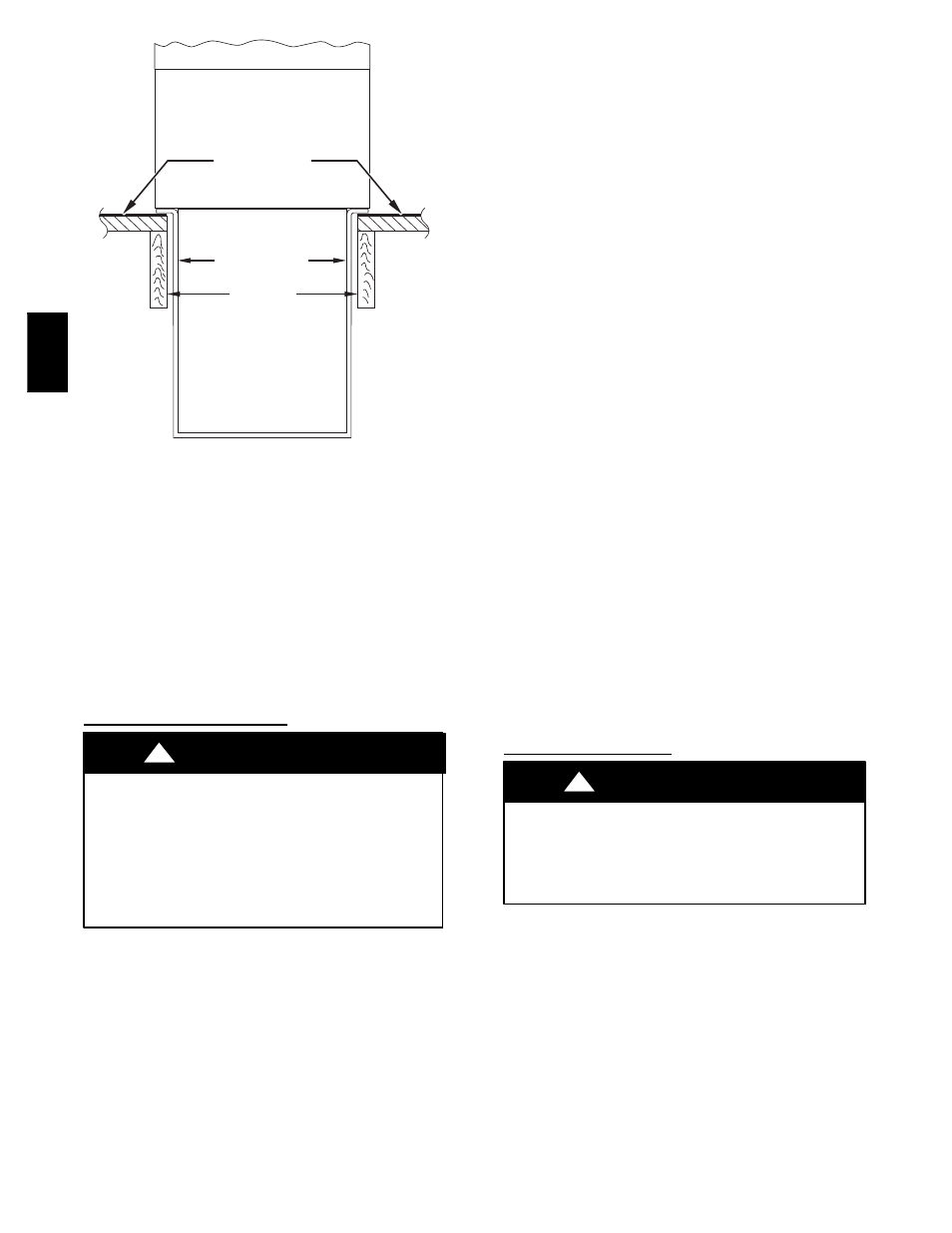

Fig. 13

--- Furnace, Plenum, and Coil Assembly or Coil Box

Installed on a Combustible Floor

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom

filler panel. (See Fig. 9.)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

HORIZONTAL INSTALLATION

FIRE, EXPLOSION, AND CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

Do not install the furnace on its back or hang furnace with

control compartment facing downward. Safety control

operation will be adversely affected. Never connect

return--air ducts to the back of the furnace.

!

WARNING

The furnace can be installed horizontally in an attic or crawl

space on either the left--hand (LH) or right--hand (RH) side. The

furnace can be hung from floor joists, rafters or trusses or

installed on a non--combustible platform, blocks, bricks or pad.

Suspended Furnace Support

The furnace may be supported under each end with threaded rod,

angle iron or metal plumber’s strap as shown. (See Fig. 15 and

16.) Secure angle iron to bottom of furnace as shown.

Heavy--gauge sheet metal straps (plumber’s straps) may be used

to suspend the furnace from each bottom corner. To prevent

screws from pulling out, use 2 #8 x 3/4--in. (19 mm) screws into

the side and 2 #8 x 3/4--in. (19 mm) screws in the bottom of the

furnace casing for each strap. (See Fig. 15 and 16.)

If the screws are attached to ONLY the furnace sides and not the

bottom, the straps must be vertical against the furnace sides and

not pull away from the furnace sides, so that the strap attachment

screws are not in tension (are loaded in shear) for reliable support.

Platform Furnace Support

Construct working platform at location where all required furnace

clearances are met. (See Fig. 2 and 17.) For furnaces with 1--in.

(25 mm) clearance requirement on side, set furnace on non--

combustible blocks, bricks or angle iron. For crawl space

installations, if the furnace is not suspended from the floor joists,

the ground underneath furnace must be level and the furnace set

on blocks or bricks.

Roll--Out Protection

Provide a minimum 17--3/4 in. x 22 in. (451 x 559 mm) piece of

sheet metal for flame roll--out protection in front of burner area

for furnaces closer than 12 inches (305 mm) above the

combustible deck or suspended furnaces closer than 12 inches

(305 mm) to joists. The sheet metal MUST extend underneath the

furnace casing by 1 in. (25 mm) with the door removed.

The bottom closure panel on furnaces of widths 17--1/2 in. (445

mm) and larger may be used for flame roll--out protection when

bottom of furnace is used for return air connection. See Fig. 17

for proper orientation of roll--out shield.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom

filler panel. (See Fig. 9.)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. This panel MUST be in place when

side return air inlet(s) is used without a bottom return air inlet.

Not all horizontal furnaces are approved for side return air

connections. (See Fig. 20.)

FILTER ARRANGEMENT

CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never operate a furnace without a filter or with filter access

door removed.

!

WARNING

There are no provisions for an internal filter rack in these

furnaces.

Refer to the instructions supplied with accessory Media Cabinet

for assembly and installation options.

This furnace requires a field--supplied external filter rack or a

suitable field--supplied substitute, such as the media cabinet. See

Table 17 for accessory list.

Refer to the instructions supplied with external filter rack for

assembly and installation options.

310AA

V