Interfaces, Stainless steel front (extra code 444) – JUMO 706581 LOGOSCREEN nt Data Sheet User Manual

Page 11

2009-12-11/00504652

Data Sheet 70.6581

JUMO GmbH & Co. KG • 36035 Fulda, Germany

Page 11/18

Interfaces

k USB interfaces

(standard)

k RS232/RS485 interface

(standard)

k RS232 interface

for barcode reader

(standard)

k Ethernet interface

(standard)

k PROFIBUS-DP interface

(extra code)

USB interfaces

With USB interfaces, a distinction is made

between the host and the device interface.

A USB memory stick can be attached to

the host interface. The device interface, in

conjunction with a standard commercial

USB cable, is used to operate the setup

program.

The paperless recorder without stainless

steel front has host and device interfaces

connected in parallel on both the front and

back panels, of which only one of each

type can ever be used. The paperless

recorder with stainless steel front has only

one host and one device interface at the

rear panel.

RS232/RS485 interface

Current process data, as well as specific

device data, can be read out via the RS232

or RS485 interface.

Data saved to the internal memory can also

be read out in conjunction with the PC

Evaluation Software PCA3000 and the PCA

Communications Software (PCC).

The RS232 interface permits a maximum

lead length of 15 m, the RS485 interface

1.2 km.

Connection is by a 9-pin SUB-D connector

on the back of the instrument. Modbus

(master and slave) protocols are available,

and the transmission mode used is RTU

(Remote Terminal Unit).

RS232 for barcode reader

A barcode reader can be attached to the

interface. The barcode reader can be used

to start or stop batch reporting, and to set

batch texts (customer information, batch

number...).

The barcode reader can also be operated

via the RS232/RS485 interface, and the

RS232 interface for the barcode reader can

also be used as a Modbus master or slave.

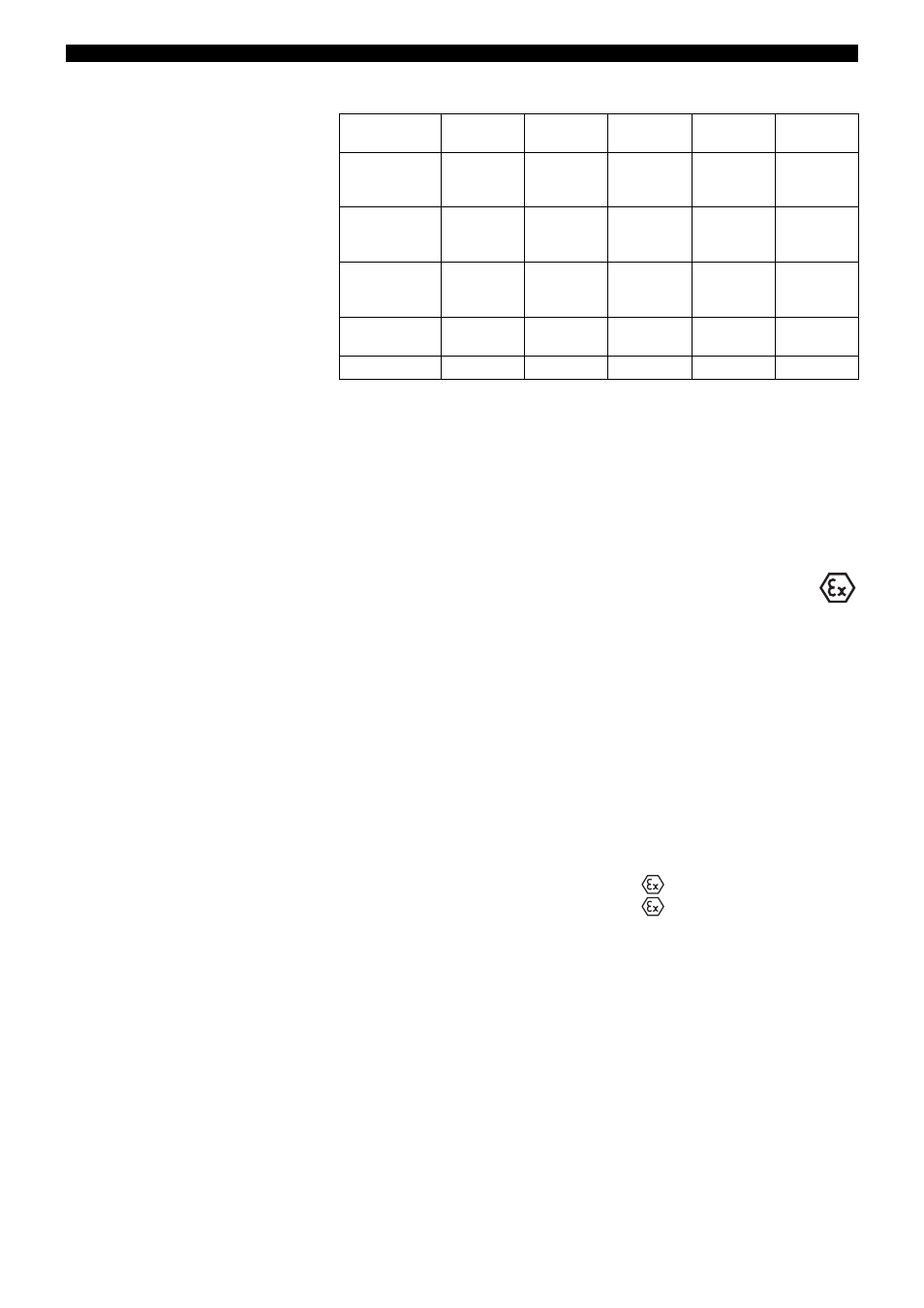

USB

Host/Device

RS232

RS485

Ethernet

PROFIBUS-

DP

External

CF card

Read current

measurement

data

yes

(device only)

yes

yes

yes

no

Write current

measurement

data

no

yes

yes

yes

no

Read out stored

measurement

data

yes

yes

yes

no

yes

Read /write

configuration

yes

yes

yes

no

yes

Write user list

yes

yes

yes

no

yes

Ethernet interface

The Ethernet interface can be used in local

networks for the communication between

the recorder and the setup program and

the PCA Communications Software. The IP

address is set permanently through the

configuration on the instrument or in the

setup program, or can be automatically

received from a DHCP server.

The integrated web server allows

simultaneous access by several PCs to

3

HTML and 3 batch pages.

Transmission protocol: TCP/IP

Network type: 10BaseT, 100BaseT

PROFIBUS-DP interface

The recorder can be integrated into a

fieldbus system according to the

PROFIBUS-DP standard via the

PROFIBUS-DP interface. This PROFIBUS

version is especially designed for

communication between automation

systems and distributed peripheral devices

at the field level.

Data are transmitted serially according to

the RS485 standard, with a maximum

12 Mbits/sec.

Using the project design tool that is

included in the delivery (GSD generator;

GSD = device master file), an application-

specific GSD file is created, which is used

to integrate the recorder into the fieldbus

system.

External CompactFlash

memory card (CF)

For paperless recorders without stainless

steel front, the external CompactFlash

memory card (CF) is used to transfer the

data from the internal memory to the PC.

Configuration data can be created on the

PC and then transferred to the recorder by

means of the memory card.

On the PC side, data on the card is

accessed using a read/write device

(CompactFlash reader/writer).

External inputs via

interface

The paperless recorder can acquire and

store up to 24 external analog inputs and

24 binary inputs.

Furthermore, the interfaces can be used to

enter comments in the event list of the

recorder.

Stainless steel front

(extra code 444)

The paperless recorder with extra code

444 (without extra code 350) may be in-

stalled in switch cabinets with at least a

simplified pressurized enclosure. Under

these conditions, use in a potentially explo-

sive athmosphere (max. zones 1 and 21) is

authorized from the front.

Notes on installation in Installation Instruc-

tions B 70.6581.4.1 must be complied with

and followed.

Paperless recorders with authorization for

explosion hazard areas, carry the following

mark on the nameplate attached to the in-

strument.

Caution: If extra code 444 is present, the

CompactFlash memory card can no longer

be used for external storage. Measurement

data can be read out via one of the inter-

faces or via a USB memory stick (from the

back).

II 2G Ex px IIC

II 2D Ex pD 21 IP65