1 setting the load fault indication, 5 settings – JUMO 709050 IPC IGBT Power Converter IPC 70A Operating Manual User Manual

Page 35

02.08 [IGBT Power Converter 70A]

35

5 Settings

Type: relay

Type:

optocoupler

In the case of a load fault, the floating contact drops out, or the collector-

emitter path of the optocoupler goes high-resistance.

The signal output is also active if the maximum temperature of the converter is

exceeded (overheat) or if the safety cut-out in the power section has been

triggered.

k

factory setting

5.12.1 Setting the load fault indication

h Connect the load

h Provide a full control signal (e.G. 20 mA at the control input)

h Adjust the „load fail adjust“ trimmer such that the yellow „load fail“ LED just

extinguishes.

- Turn clockwise = LED lights up

- Turn counter-clockwise = LED extinguishes

h If necessary, continue turning counter-clockwise to reduce the activation

threshold. 1.5 turns of the potentiometer change the load current by

approx. 10% of the converter rated current.

709050 /

X1 -

XX

-

XXX -

XXX - 070

/ 252

709050 /

X1 -

XX

-

XXX -

XXX - 070

/ 257

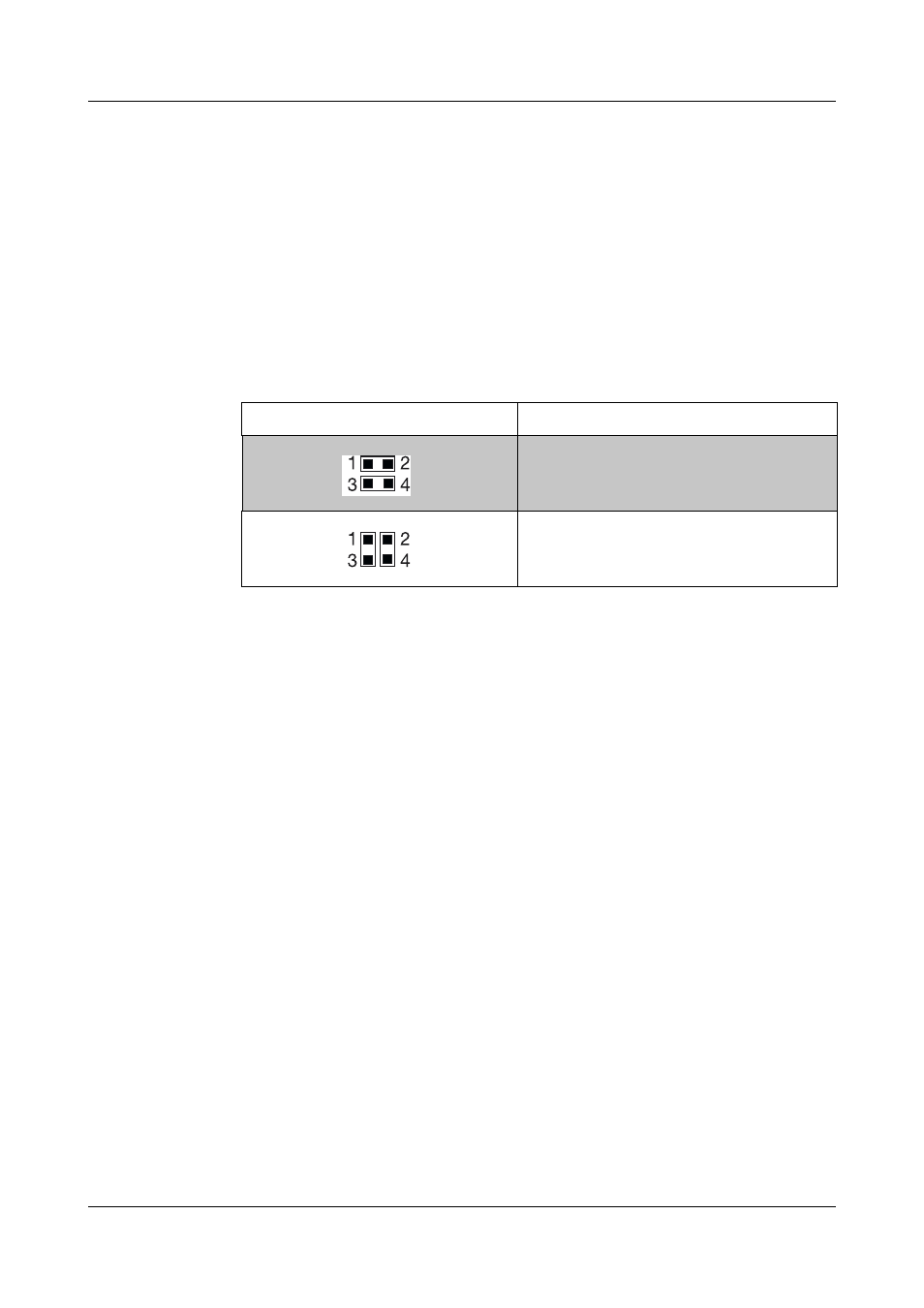

Jumper setting

Response

Underload detection

Overload detection

H

The total and partial load failure monitoring (underload) also allows

overload monitoring. For this purpose, both jumpers on the pin

strip X106 must be turned through 90°.

v Chapter 5.2 „Setting switches and jumpers“

H

The partial load setting must be made after the current limit has

been set. If the current limit setting is changed, this will also affect

the setting of the partial load fault detection.

This must be corrected accordingly, if necessary.