Countercooling – JULABO HT60-M3 High Temperature Circulator User Manual

Page 34

Preparations

34

5.8. Countercooling

Caution:

Securely attach all tubing to prevent slipping.

From a working temperature of 200°C on always work with counter-cooling.

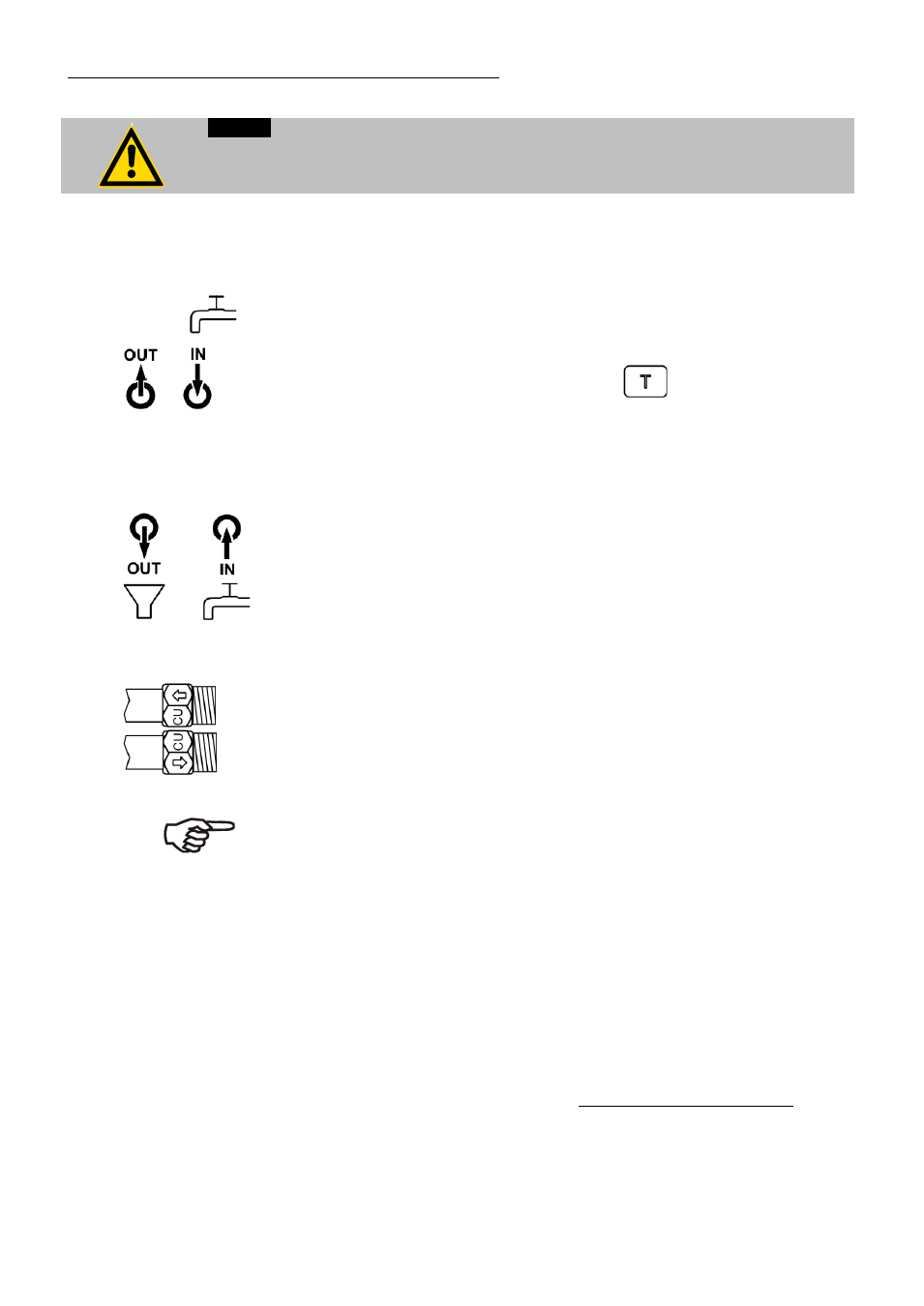

HT60

(45)

(44)

Thread M2 / M3 2 /

∠37 +

Barbed fittings 8 mm ID

CU

(47)

(46)

Tube connections 10 mm ID

On the HT60-circulator we distinguish two different cooling devices:

(Cooling water see page 16)

1. A cooling coil in the cooling zone for cooling water.

Without C.U.-cooling unit

The cooling wate is directly connected to the connections (44, 45).

Flow of cooling water: app. 2 l/min at

>150 °C.

or

A magnetic valve for clocked cooling water is connected to the

connection (44)

When required the control exit opens and closes the magnetic valve.

JULABO Order no..

8 980 704

Magnetic valve

With assembled C.U.-cooling unit

the cooling water is connected to the connections (47, 46)

The flow of cooling water is controlled automatically.

HT60

Returnf (52)

HT60

Feed (53 )

Thread M2 / M3 6x1

2. A cooling coil in the C.U.-cooling unit for rapid cool-down of the

tempering liquid

Via the pump connections (52, 53) the tempering liquid is led through

the CU-unit.

The heat is drained via the cooling water (47).

Comments:

• With an assembled C.U.-cooling unit the menu-point CoolingMax has

to be set to a value of >0. So, the automatic control of the cooling can

become active.

• In the C.U.-unit water and oil temperature are supervised at each

outflow.

The oil flow-through is interrupted

when the oil temperature is app. 150 °C and

the water temperature is app. 80 °C.

C.U.-cooling unit:

Cooling capacity at 2 l/min flow of cooling water.

Temperature

[°C] 350

250

150

75

Cooling capacity

[kW]

12

8

4

1