1 general data – INFICON HPG400-SP ATM to High-Vacuum Gauge (Profibus) User Manual

Page 6

6

tira36e1-a (0310) BPG/HPG400 v1.cp

1 General Data

The gauge supports all data rates defined in the EN 50170 standard (

→ [8]) up

to 12 Mbaud. Automatic data rate setting is supported. Alternatively, a fixed data

rate can be selected.

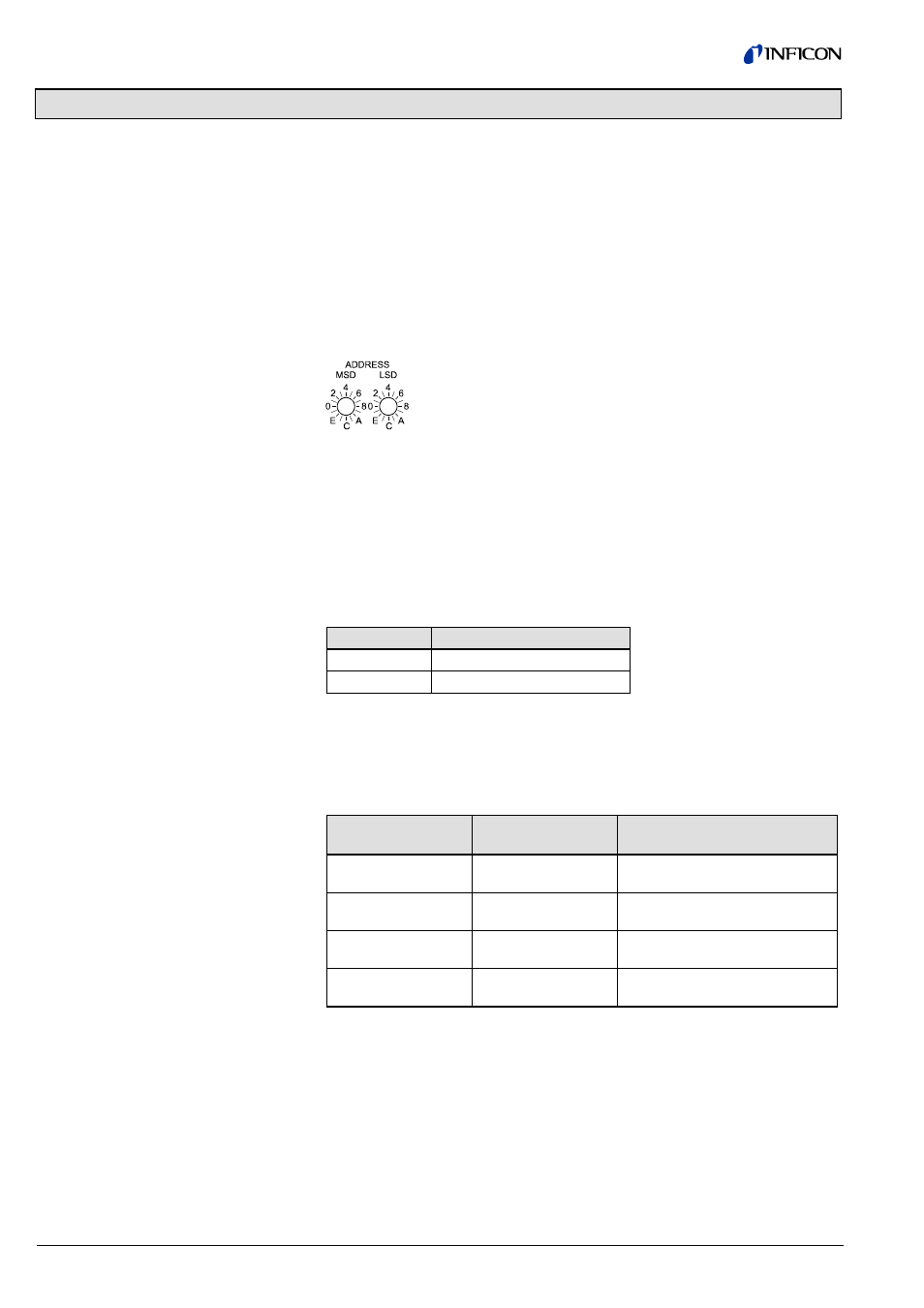

The device address (

node address) must be set via two rotary switches when the

gauge is installed.

For unambiguous identification of the gauge in a Profibus environment, a node

address is required. The node address setting is made on the gauge.

The node address (0 … 125

dec

) is set in hexadecimal form

(00 … 7D

hex

) via the "ADDRESS" switches. The "MSD" switch is

used for setting the high-order address nibble and the "LSD"

switch for defining the low-order address nibble.

The node address is polled by the firmware when the gauge is switched on. If the

setting deviates from the stored value, the new value is taken over into the

NVRAM. If a value >7D

hex

(>125

dec

) is entered, the node address setting currently

stored in the device remains valid. However, the address can be set via the

Profibus master with the "Set Slave Address" service. This address setting will be

stored in the EEPROM of the gauge.

The ident numbers assigned to the gauges by the PNO (

→ [7]) are:

Gauge

Ident number (hexadecimal)

BPG400-SP

06A9

HPG400-SP

06A8

Depending on the standard telegrams used (

→ section "Cyclic Message Tele-

grams"), the following configuration data have to be transmitted to the gauge during

the configuration phase:

Standard telegram

Master

⇒ Slave

Standard telegram

Slave

⇒ Master

Configuration data

-

2

0x44, 0x84, 0x05, 0x05, 0x05,

0x03

-

3

0x44, 0x86, 0x05, 0x05, 0x05,

0x08

1

4

0xC6, 0x87, 0x8c, 0x0A, 0x0A,

0x05, 0x05, 0x05, 0x03

1

5

0xC6, 0x87, 0x8E, 0x0A, 0x0A,

0x05, 0x05, 0x05, x08

1.1 Data Rate

1.2 Device Address

1.3 Ident Number

1.4 Configuration Data