ERICO S-Series LENTON LOCK User Manual

Page 2

INSTRUCTION SHEET

TECHNICAL SUPPORT: PDF121_G 2 of 2

2009,2010,2012,2014 ERICO International Corporation

www.erico.com

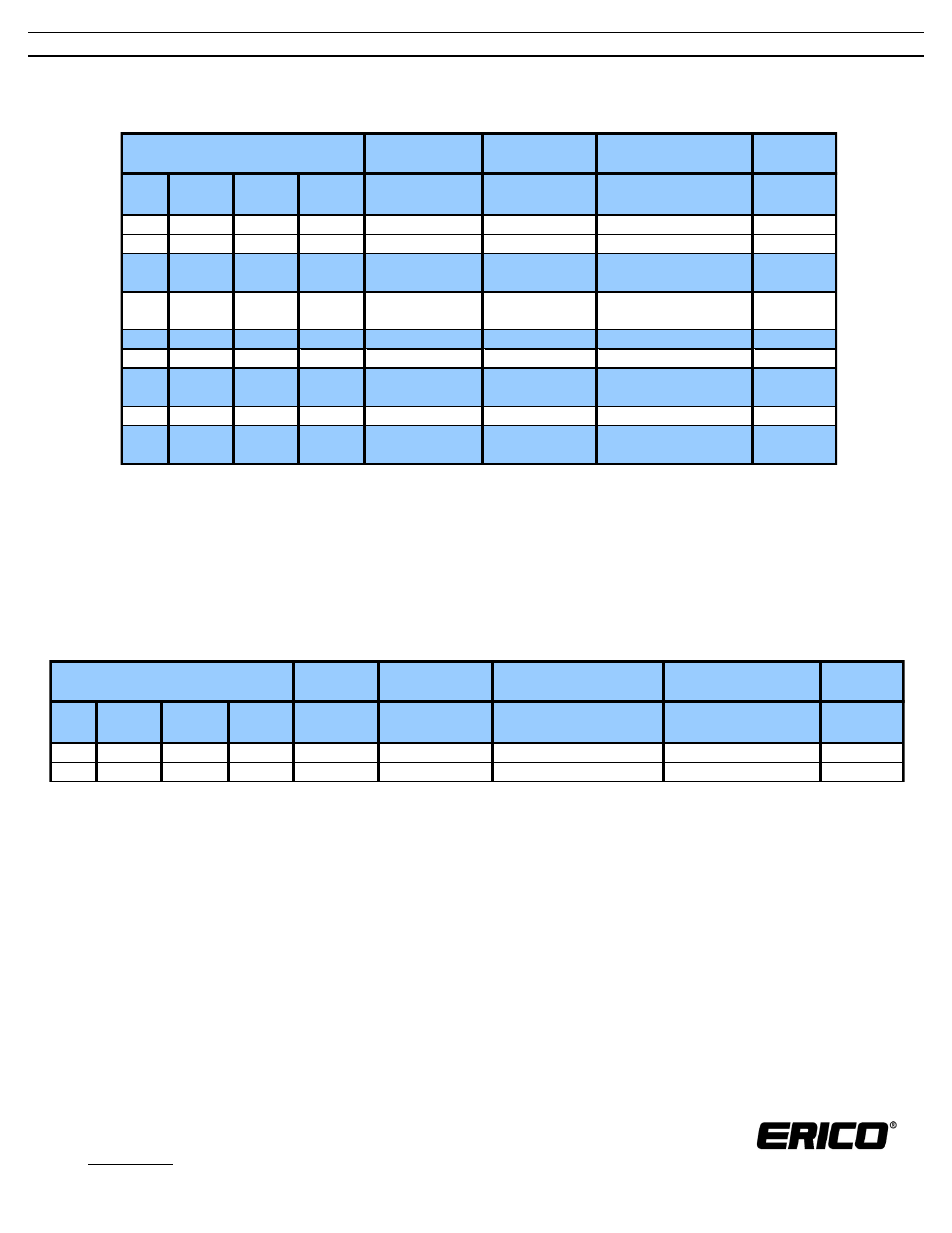

Table 1. Torque values for coupler sizes 12(#4) through 36(#11)

Pre-Torque is not required for these sizes

Coupler

Number of

Bolts

In-lb

Metric

Canada

Soft

Metric

in

mm

ft-lb

N-m

-

10

-

10

LL12S1

1/2

13

150

205

4

#4

12

10 M

13

LL12S1

1/2

13

150

205

4

-

14

-

-

LL16S1

1/2

13

150

205

4

#5

16

15 M

16

LL16S1

1/2

13

150

205

4

-

18

-

-

LL20S1

1/2

13

150

205

6

#6

20

20 M

19

LL20S1

1/2

13

150

205

6

#7

22

-

22

LL22S1

5/8

16

250

340

6

#8

25

25 M

25

LL25S1

5/8

16

350

475

6

#9

28

30 M

29

LL28S1

5/8

16

350

475

8

-

30

-

-

LL28S1

5/8

16

350

475

8

#10

32

32

LL32S1

13/16

21

550

750

6

-

34

-

-

LL36S1

13/16

21

550

750

8

#11

36

35 M

36

LL36S1

13/16

21

550

750

8

Rebar Designation

Socket Size

Average Torque to

Shear Bolts

Alternate Step 4:

For sizes 43 (#14) and 57 (#18) a two-step torque sequence is required.

Using a nut runner, pre-torque the bolts beginning in the center of the coupler and working to the outside (A to C) using pre-torque values in

table 2. Then go back to bolt A and finish tightening the bolts, once again beginning in the center of the coupler and working to the outside (A

to C), until bolt heads shear off. A nut runner must be utilized for the final tightening of the bolts.

Table 2. Alternate Step 4: Two-step torque sequence for coupler sizes 43(#14) and 57(#18)

Pre-Torque the bolts to the specified torque before final tightening.

Coupler

Number of

Bolts

In-lb

Metric

Canada

Soft

Metric

in

mm

ft-lb

N-m

ft-lb

N-m

#14

43

45M

43

LL43S1

13/16

21

500

680

660

900

12

#18

57

55M

57

LL57S1

1

25

750

1020

960

1300

14

Rebar Designation

Socket Size

Pre Torque

All Bolts

Average Torque to

Shear Bolts

If bolt head does not shear, the installer should verify the appropriate torque was met (see Table 2). If a minimum cover must be maintained,

the head can be cut off after the proper torque has been applied.

If during installation the bolt strips, as defined by a loss of resistance to the applied torque, stop the installation immediately. Remove the un-

sheared damaged bolt. Contact ERICO for LENTON

Technical Support

Repeat procedure for other end of the sleeve.

Transition Splices:

LENTON

LOCK is designed for use as a one-step transition/reducer splice on all type of rebar.

Contact ERICO for details.

Closure Pour Splices:

Refer to instruction sheet PDF113 for details. Additional copies of instructions and application

information are available at www.erico.com