Cadweld, Rail grounding connections – joint head bonds – ERICO CADWELD Rail Grounding Connections – Joint Head Bonds User Manual

Page 2

!

WARNING:

The area of the rail where the head bond will be applied

and the bond terminals must be clean and dry. Failure to comply

can cause poor bonding, excessive weld porosity, and/or spewing molten

welding material with the potential for serious burns to the worker.

2. Use abrasive cloth or wire brush on the bond terminals if needed to

remove surface oxidation.

!

CADWELD

®

Rail Grounding Connections – Joint Head Bonds

Refer to the mold tag for applicable instruction sheets.

IPRGJ_B

IPRGJ_B R1074IS10WWEN PUR0312

!

!

!

!

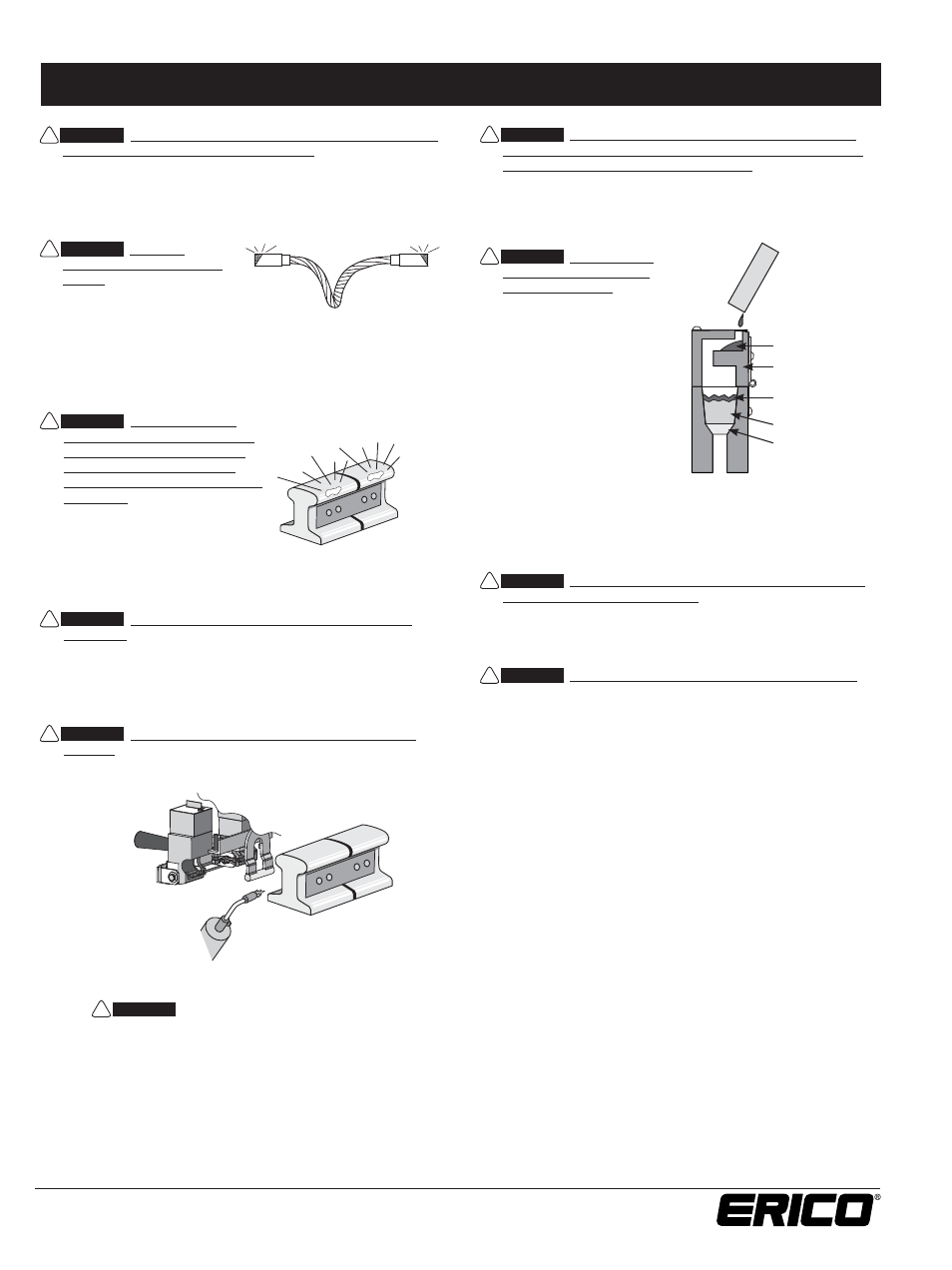

FIGURE 4

CAUTION:

The bond

terminals must have a bright

surface. Failure to comply with

this may result in a less than

optimal weld. See Figure 4.

WARNING:

The area of the rail

head to be bonded must be lightly

ground to a bright fi nish with no

visible scratch marks or gouges

(normal uniform fi nishing marks are

acceptable). Failure to observe this may

result in visible scratches or gouges due

to overly aggressive grinding that are

potential crack initiators and that may

lead to rail breaks causing derailment

accidents with property damage, injury

and death to others. See Figure 5.

3. Lightly grind the rail surface using an ERICO approved grinding wheel

that is self-cleaning or a CADWELD

®

brand Rail Head and Web Cleaner

(Part SBB394C). Grinding wheels with resin binders tend to leave a

surface

fi lm that may contaminate the surface, interfering with the

achievement of an optimum bond and causing weld porosity.

FIGURE 5

FIGURE 6

CAUTION:

Grinding must not be done more than 4 hours prior

to bonding. If the time lapse is longer, suffi cient contaminating rust may

re-form requiring additional grinding. Failure to observe this may result in

a less than optimum bond.

4. Dry the mold and rail by heating them to about 250°F (120°C) with

a small propane torch.

WARNING:

The rail and mold must both be warmed to drive off

moisture. Failure to observe this may result in weld spatter with the

potential for serious burn injury, and a less than optimum bond with

excessive porosity. See Figure 6.

!

!

!

!

WARNING:

Rebonding over the application of an earlier bond is

only permissible in areas of minimal stress such as the head of the

rail within the confi nes of the joint/splice bar! Remove the original

bond by grinding down to a smooth layer of parent rail steel. The new bond

can then be made in the same location as the previous bond. Failure to

observe this may result in a rail break leading to property damage, injury

or death to others.

FIGURE 7

Disk

Welding Material

1/2 Starting Material

Crucible Cover

1/2 Starting Material

CAUTION:

Install only the

specifi ed welding material

in the mold crucible. Use

only the welding material

size that is specifi ed on the

mold. ERICO brand of welding

material (F80) is formulated

specifi cally for use with rail

steels; it is packaged in a blue

tube with a yellow cap. Dump

all of the welding material into

the crucible, then carefully tap

the tube on a hard surface to

loosen the starting material

from the bottom of the tube

and distribute half on top of

the welding material, close

the mold cover, and pour the remainder in the opening of the mold cover.

See Figure 7. Failure to comply may result in diffi culty getting the reaction

started and/or an unacceptable weld.

CAUTION:

Avoid direct eye contact with the “fl ash” of light from

the ignition of the starting material.

5. Position yourself upwind of the mold, on the fi eld side of the rail.

Place the tip of the fl int igniter at the cover opening and ignite.

Remove the igniter quickly to prevent fouling.

CAUTION:

Allow 15 seconds for mold cooling after the reaction.

This will permit the molten metal to solidify. Then carefully disengage

the welder device and pull the mold straight back from the rail. Failure

to observe this may result in mold damage and its premature scrapping.

Molds can generally be re-used up to 50 times.

6. Carefully open the mold cover and break up the slag in the crucible

using the blade of the mold cleaning tool. Dump the slag from the

crucible and remove slag from the taphole using the curved end of

the mold cleaner. Dump slag in the ballast, not onto the ties.

7. Check the molds for breakage or residual slag before proceeding

with the next weld.

Note: If you have any questions or require further instructions, or would

like training, contact ERICO at 1-800-447-7245.

WARNING:

1. Connections should not be made to load bearing rail steel other than at the neutral axis of the rail or at the head of the rail within

the

confi nes of the joint/splice bar.

2. All connections to rail steel should only be made where the rails are fully supported, or to rail that is non-load bearing in its use.

3. The welding material size for the connection to rail steel should not be greater than 250 grams (which, in general, corresponds

to a maximum cable size of 500 kcmil (240 mm

2

).

Copyright ©2010, 2012 ERICO International Corporation. All rights reserved.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

www.erico.com

2