Cadweld, Plus rail track connection web bonds – ERICO CADWELD PLUS Rail Track Connection Web Bonds User Manual

Page 4

4

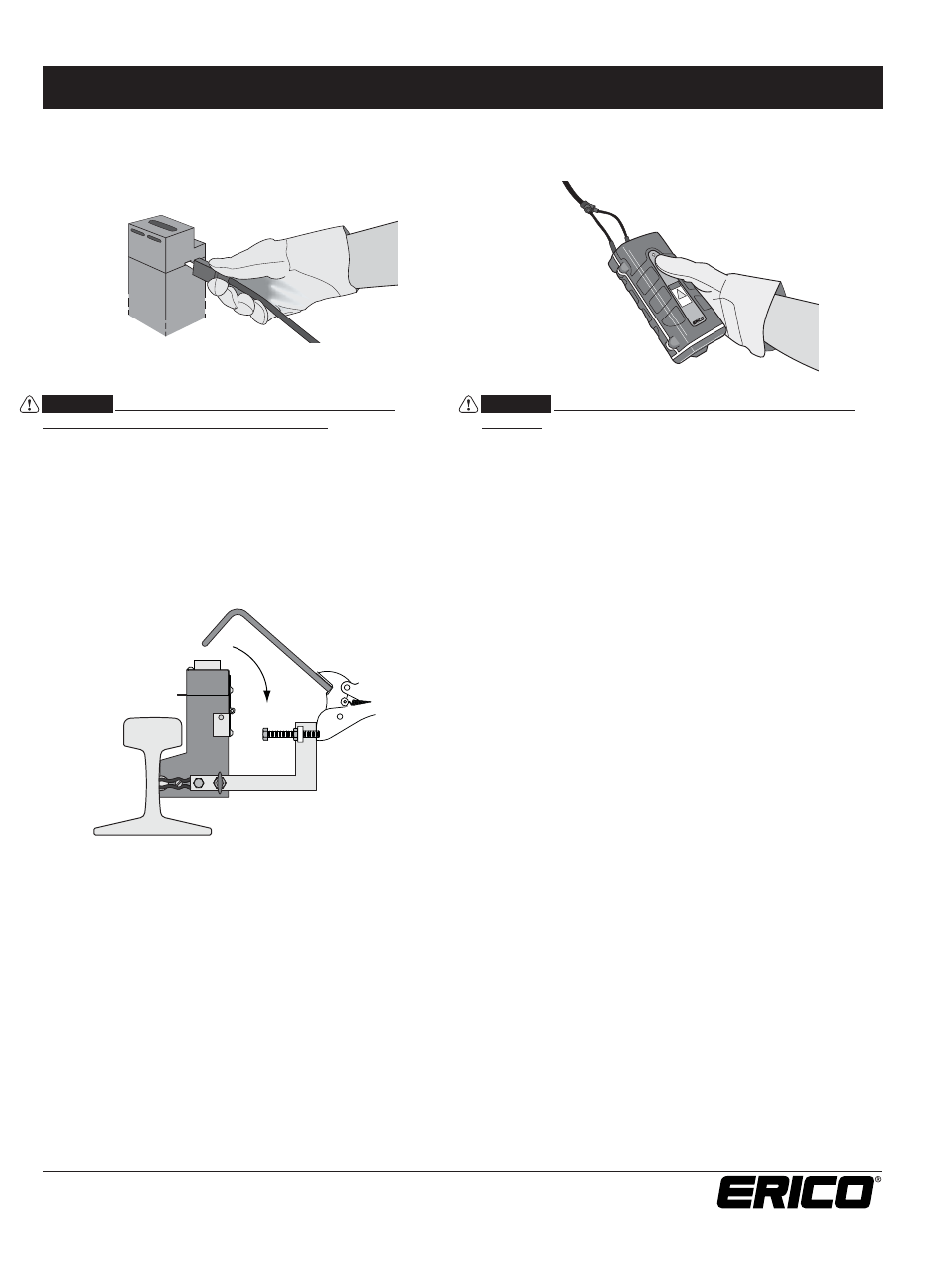

4. Attach Control Unit termination clip to ignition strip, align the

strip and close the cover. See Figure 12.

6. Press and hold Control Unit operator button until the ready

light turns off and wait for ignition. See Figure 14.

CAUTION:

Allow 15 seconds for mold cooling after the

reaction. This will permit the molten metal to solidify. Then

carefully disengage the welder device and pull the mold straight

back from the rail. Failure to observe this may result in mold

damage and its premature scrapping. Molds can generally be

re-used up to 50 times.

7. Carefully open the mold and remove the expended steel cup

— no special disposal required.

8. Break up the slag in the crucible using the blade of the mold

cleaning tool. Dump the slag from the crucible and remove

slag from the taphole using the curved end of the mold

cleaner. Dump slag in the ballast, not onto the ties.

9. Check the molds for breakage or residual slag before

proceeding with the next weld.

Note: If you have any questions or require further instructions,

or would like training, contact ERICO at 1-800-447-7245.

CAUTION:

Install only the specifi ed CADWELD PLUS

welding material cup in the mold crucible. Use only the

welding material size that is specifi ed on the mold. ERICO

brand of welding material (F80) is formulated specifi cally for

use with rail steels.

5. Place welder against rail. Hold fi rmly if TB5 style or clamp if

T21 style. Clamp is adjustable for rail sizes. Check that mold

face

fi ts against rail and bond terminal is held against rail.

NOTE: Clamp on T21 style can be swung out of way to

make hand held welder. See Figure 13.

IPRSWCP_B R1058IS12WWEN PUR1013

www.erico.com

Copyright ©2008, 2010, 2012, 2013 ERICO International Corporation. All rights reserved.

CADDY, CADWELD, CRITEC, ERICO, ERIFLEX, ERITECH, and LENTON are registered trademarks of ERICO International Corporation.

FIGURE

12

FIGURE

13

CADWELD

®

PLUS Rail Track Connection Web Bonds

Refer to the mold tag for applicable instruction sheets.

IPRSWCP_B

FIGURE

14