Enerpac SU7-Series User Manual

Page 8

6.2 Hydraulic Connections

To make port connections, install fittings rated for 70

bar [1000 psi].

DO NOT use thread sealant. Sealing is accomplished

by using an O-Ring on the fitting boss. Lubricate the

O-Ring prior to assembly.

When designing your hydraulic circuit, consider

the factors listed in Section 4.1 of this manual.

For additional information about plumbing hydraulic

circuits, refer to the Enerpac Workholding product

catalog.

Table 11 - Cylinder Ports

Cylinder Capacity

BSPP Port Size

2,0 kN [441 lbs]

G ¹⁄

8

3,5 kN [769 lbs]

G ¹⁄

8

5,0 kN [1111 lbs]

G ¹⁄

8

7,0 kN [1570 lbs]

G ¼

9,0 kN [2019 lbs]

G ¼

20,0 kN [4490 lbs]

G ¼

6.3 Vent Plug

Single-acting cylinders have a vented plug on the left

side of the cylinder when you are facing the hydraulic

ports. To prevent entry of chips and coolant, the vent

plug must not be removed. If the vent plug is subjected

to a continuous coolant flood condition, attach tubing

to the port using a BSPP fitting, and run the tubing to a

non-contaminated area of the fixture.

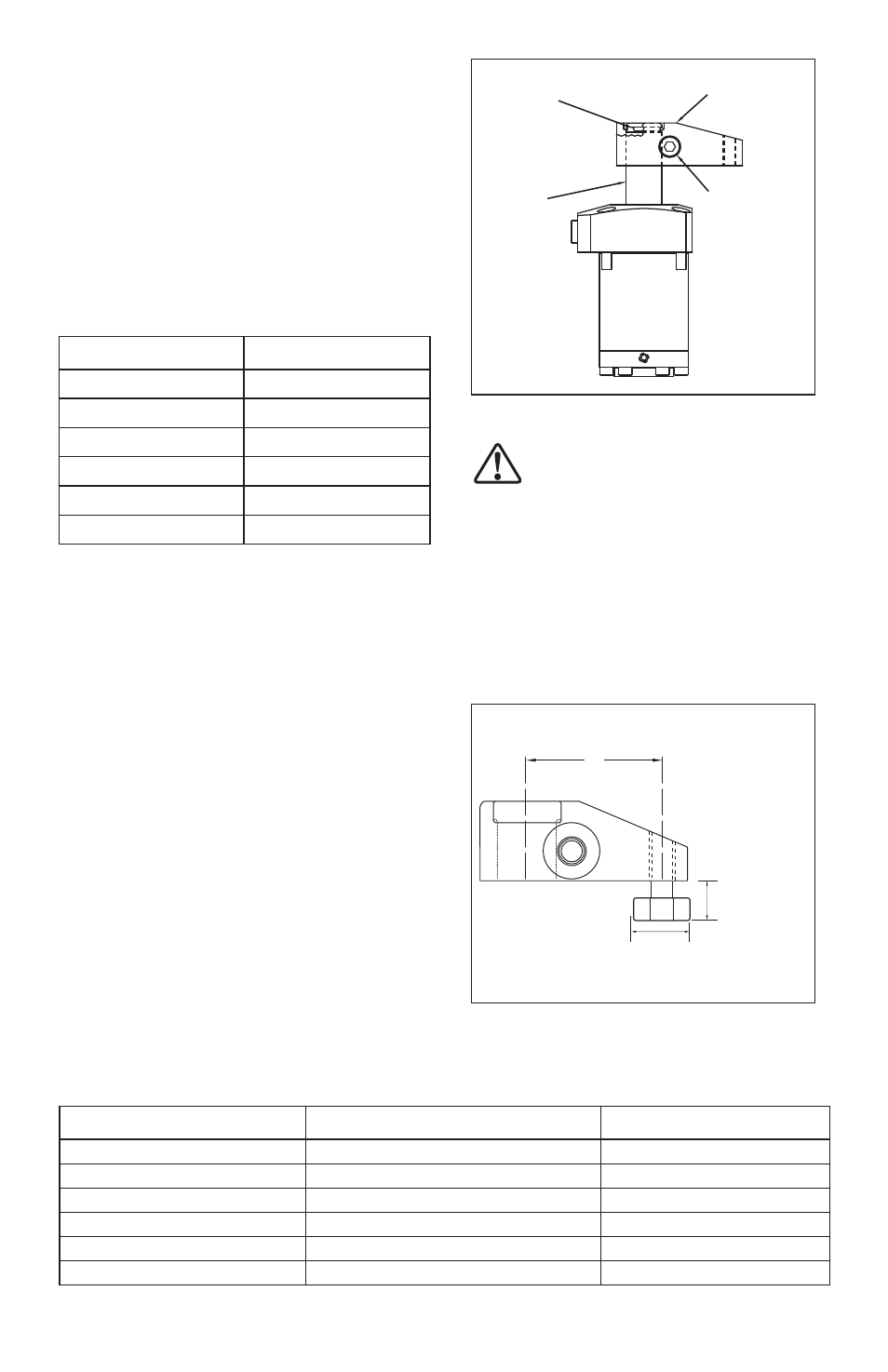

6.4 Attaching Clamp Arm

1. Remove the retaining ring from the top of the

plunger.

2. Slide the clamp arm down over the plunger and

use a pliers to push the retaining ring back onto

the plunger groove. Orient the retaining ring so the

retaining ring gap will face the back of the clamp

arm. See Figure 4.

3. Move the clamp arm up until it is firmly against the

retaining ring and in the desired position. While

maintaining this position, torque the clamp arm bolt

to specification shown in Table 12.

Retaining

Ring

Plunger

Clamp Arm

Clamp Arm

Bolt

Figure 4, Attaching Clamp Arm

CAUTION: Inadequate torquing of the

clamp arm bolt could cause the arm to slip

during operation. BE SURE TO USE

QUALITY 12.9 DIN 912 (GRADE 8) SOCKET HEAD CAP

SCREWS (supplied with standard clamp arms).

6.5 Contact Bolt Clearance

When using a contact bolt with upper flange body style

cylinders, you must be certain that the bolt head will

clear the cylinder upper flange during operation. The

clamp arm must be long enough for the bolt head to

clear the upper flange as the arm swings down. Refer to

Figure 5 and Table 13.

P

Note: Bolt head diameter

must not be larger than

16 mm [0.63 in.]

Max. Bolt Length

(see Table 13)

Figure 5, Contact Bolt Clearance

8

Table 12 - Clamp Arm Bolt Torque

Cylinder Capacity

Bolt Type

Torque

2,0 kN [441 lbs]

M8 x 1,0 x 20 mm long

32,5-39,0 Nm [24-29 ft-lbs]

3,5 kN [769 lbs]

M8 x 1,0 x 25 mm long

32,5-39,0 Nm [24-29 ft-lbs]

5,0 kN [1111 lbs]

M8 x 1,0 x 25 mm long

32,5-39,0 Nm [24-29 ft-lbs]

7,0 kN [1570 lbs]

M10 x 1,25 x 25 mm long

60,0-72,0 Nm [44-53 ft-lbs]

9,0 kN [2019 lbs]

M10 x 1,25 x 25 mm long

60,0-72,0 Nm [44-53 ft-lbs]

20,0 kN [4490 lbs]

M12 x 1.25 x 35 mm long

95,5-108,0 Nm [70-80 ft-lbs]

“P” Dimension - CAS Series Arm

(see Table 13)