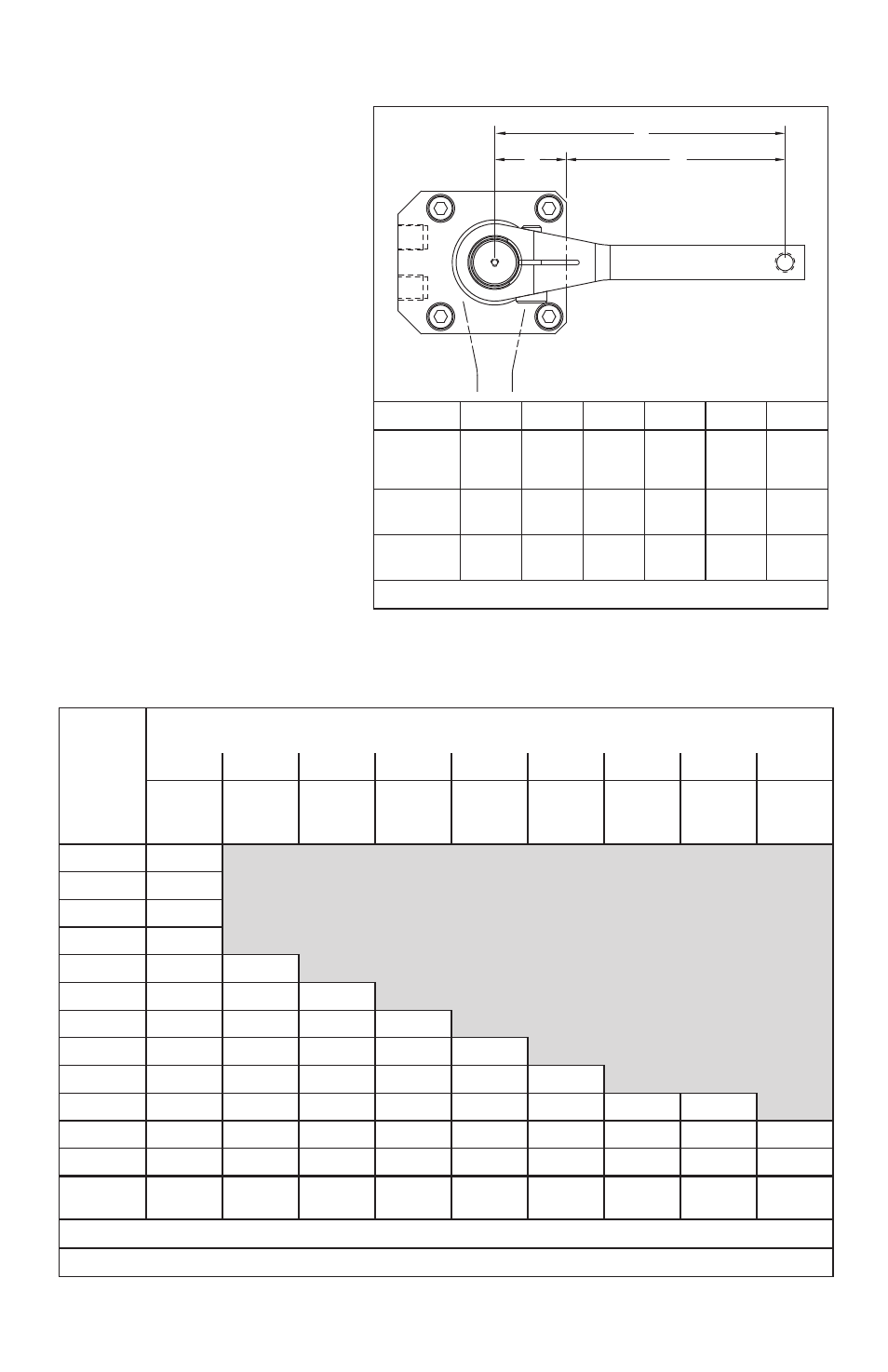

Not recommended, Table 3 - clamp arm dimensions “m”, “n” and “p, 1 clamping force vs. arm length – Enerpac SU7-Series User Manual

Page 3

3

Table 4 - Clamping Force vs. Arm Length - 2 kN Models

Pressure

(bar)

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

10*

20

30

40

50

60

70

80

95**

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

70

1,96

65

1,82

60

1,69

55

1,56

NOT RECOMMENDED

45

1,25

1,33

40

1,11

1,20

1,18

35

0,98

1,07

1,02

1,02

30

0,85

0,89

0,85

0,85

0,85

25

0,71

0,76

0,71

0,71

0,71

0,71

20

0,56

0,62

0,58

0,58

0,58

0,58

0,58

0,56

15

0,42

0,44

0,40

0,40

0,40

0,40

0,40

0,40

0,38

10

0,29

0,31

0,27

0,27

0,27

0,27

0,27

0,27

0,27

Maximum

Flow (lpm)

0,41

0,31

0,25

0,21

0,18

0,15

0,14

0,12

0,11

Notes: * CAS-722 standard arm ** CAL-722 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

Table 3 - Clamp Arm Dimensions “M”, “N” and “P”

M

P

N

Size

2 kN

3,5 kN

5 kN

7 kN

9 kN

20 kN

Dimension

“M”

See

Table

4

See

Table

5

See

Table

6

See

Table

7

See

Table

8

See

Table

9

Dimension

“N”

25 mm

27 mm

30 mm

37 mm

38 mm

49 mm

Dimension

“P”

M + N

M + N

M + N

M + N

M + N

M + N

Conversion Information: 1 mm = 0.039 in.

3.1 Clamping Force vs.

Arm Length

Refer to the tables in this section when

selecting the swing cylinder model and

arm length for your application.

IMPORTANT: As the arm length

increases, the maximum allowable

pressure and flow rate decreases.

Exceeding these limits may cause

damage to the product. If the pressure

required for a desired clamping force

and arm length exceeds the specified

limits, select a higher capacity swing

cylinder model.

(REF)