0 clamp arm machining specifications – Enerpac SU7-Series User Manual

Page 11

11

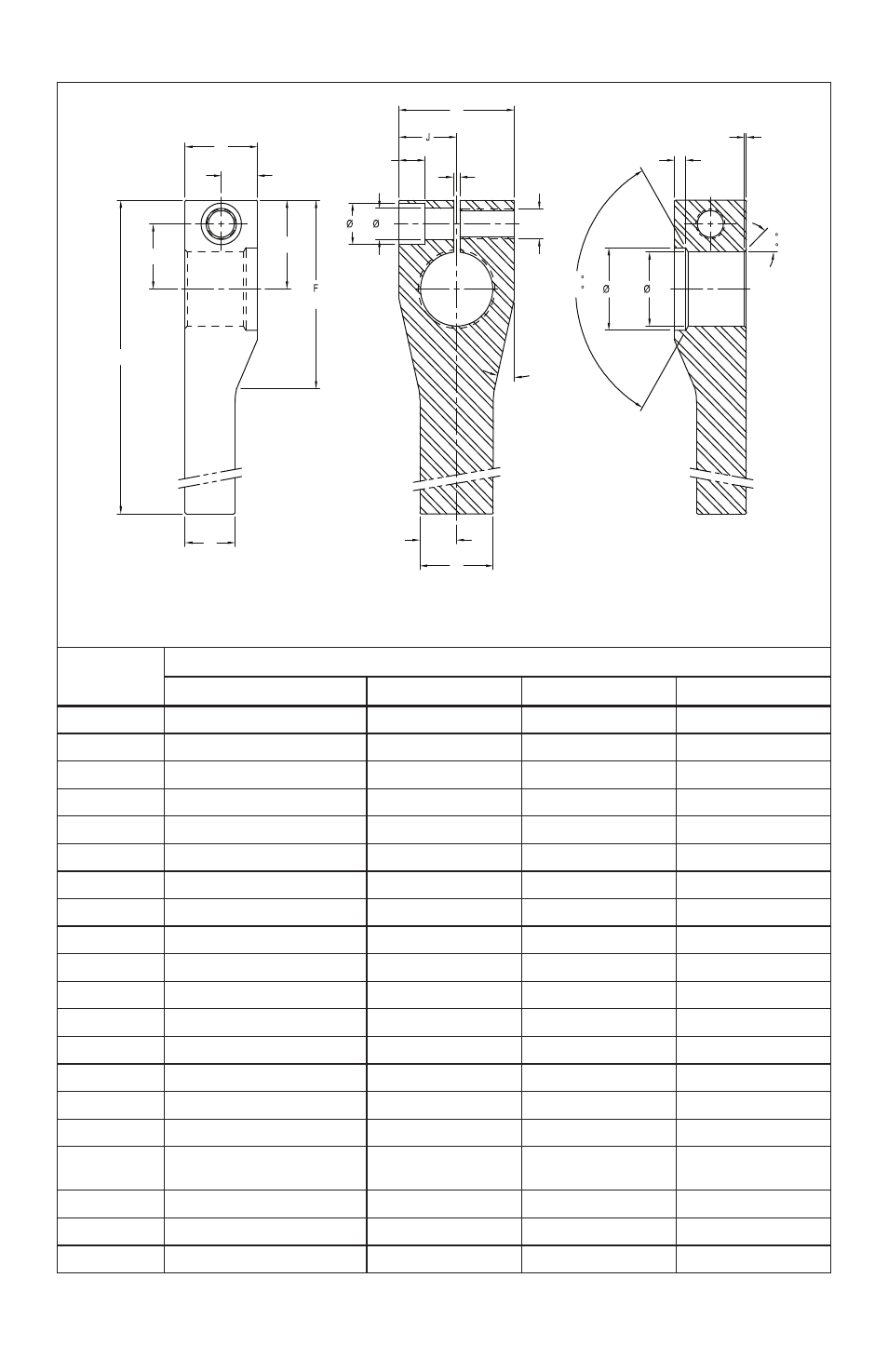

10.0 CLAMP ARM MACHINING SPECIFICATIONS

F

G

K

M

N

R

C

J

L

2.3

125

115

S

T

50

40

V

U

A

H

B

E

D

P

Q

Item

Dimensions in millimeters [inches] unless otherwise noted

2,0 kN

3,5 kN and 5,0 kN

7,0 kN and 9,0 kN

20,0 kN

A

25 [0.99]

27 [1.06]

30 [1.18]

38 [1.49]

B (Max.)

150 [5.90]

190 [7.48]

190 [7.48]

210 [8.26]

C

30 [1.18]

34 [1.34]

40 [1.57]

48 [1.89]

D

16 [0.63]

16 [0.63]

18 [0.70]

21 [0.82]

E

19,5 [0.77]

20 [0.79]

22 [0.87]

26 [1.02]

F (3 places)

67 [0.26]

84 [3.30]

86 [3.39]

100 [3.94]

G

29 [1.14]

31 [1.22]

34 [1.34]

40 [1.58]

H

12,5 [0.49]

13,5 [0.53]

15 [0.59]

19 [0.74]

J

15 [0.59]

17 [0.67]

20 [0.79]

24 [0.94]

K (Dia.)

ш 13,5 [0.53]

ш 13,5 [0.53]

ш 16,5 [0.65]

ш 18,5 [0.73]

L

9 [0.35]

11 [0.43]

11 [0.43]

13 [0.51]

M (Dia.)

ш 8,5 [0.33]

ш 8,5 [0.33]

ш 10,5 [0.41]

ш 12,5 [0.49]

N (thread)

M8 x 1,25

M8 x 1,25

M10 x 1,5

M12 x 1,25

P

6 [0.23]

8 [0.31]

9 [0.35]

12,75 [0.50]

Q

12 [0.47]

16 [0.63]

18 [0.71]

25,5 [1.00]

R (2 places)

21º - 23º

21º - 23º

21º - 23º

21º - 23º

S (Dia.)

ш 22,75 - 23,00

[0.895 - 0.905]

ш 24,75 - 25,00

[0.974 - 0.984]

ш 27,75 - 28,00

[1.092 - 1.102]

ш 35,50 - 36,00

[1.397 - 1.417]

T (Dia.)

ø 20 H8

ø 22 H8

ø 25 H8

ø 32 H8

U

3,8 - 4,3 [0.15 - 0.17]

3,8 - 4,3 [0.15 - 0.17]

3,8 - 4,3 [0.15 - 0.17]

4,7 - 5,3 [0.19 - 0.21]

V

1,0 - 2,0 [0.04 - 0.09]

1,0 - 2,0 [0.04 - 0.09]

1,0 - 2,0 [0.04 - 0.09]

1,0 - 2,0 [0.04 - 0.09]

IMPORTANT: Refer to Section 3.1 to

determine the maximum clamp arm

length and pressure for the desired

clamping force.

3 PLACES

2 PLACES