Not recommended, 0 description, 1 preliminary information – Enerpac SU7-Series User Manual

Page 6

6

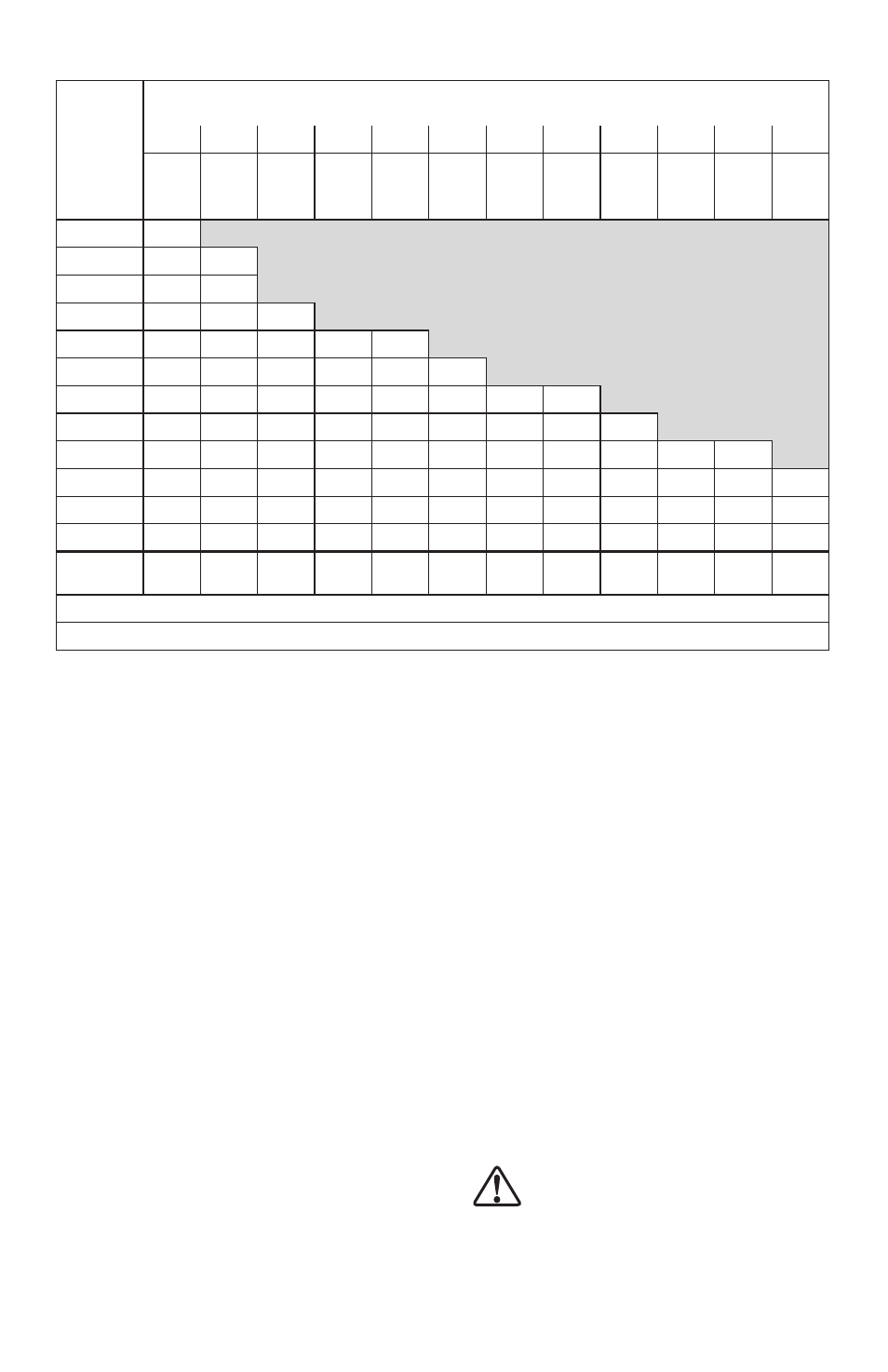

Table 9 - Clamping Force vs. Arm Length - 20 kN Models

Pressure

(bar)

Dimension “M” (See Graphic in Table 3)

Flange Face to Clamping Point - In Millimeters

19*

20

20

20

20

60

70

80

90

100

120

125**

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

Clamp

Force

(kN)

70

19,97

65

18,64

19,79

60

17,21

18,24

55

15,79

16,72

16,41

NOT RECOMMENDED

45

12,90

13,70

13,30

13,30

13,26

40

11,48

12,19

11,70

11,70

11,70

11,65

35

10,05

10,63

10,10

10,10

10,05

10,05

10,01

10,01

30

8,58

9,12

8,67

8,67

8,67

8,67

8,63

8,63

8,63

25

7,16

7,61

7,16

7,16

7,12

7,12

7,12

7,07

7,03

6,98

6,98

20

5,74

6,09

5,74

5,74

5,74

5,74

5,74

5,69

5,65

5,60

5,60

5,56

15

4,31

4,58

4,27

4,27

4,27

4,23

4,23

4,23

4,23

4,18

4,18

4,14

10

2,85

3,02

2,8

2,80

2,80

2,78

2,76

2,76

2,76

2,76

2,76

2,71

Maximum

Flow (lpm)

4,10

4,05

3,71

3,42

3,17

2,96

2,77

2,61

2,47

2,33

2,22

2,16

Notes: * CAS-7202 standard arm ** CAL-7202 long arm

Conversion Information: 1 mm = 0.039 in. 1 kN = 224.82 lbs. 1 bar = 14.5 psi 1 lpm = 61.02 in³/min

4.0 DESCRIPTION

Enerpac 70 Bar swing cylinders are designed to

swing 90° in a clockwise or counter-clockwise

direction. Single-acting and double-acting models are

available. Clamp arms are not supplied with cylinders.

Clamp arms can be purchased separately or may be

fabricated according to the specifications in Section

10.0 of this manual.

4.1 Preliminary Information

IMPORTANT: Failure to read and follow these

instructions may lead to system malfunction or

product failure, and could invalidate your warranty.

1. High flow rates can lead to excessive cylinder

speed which can damage the index mechanism.

Hydraulic pressure and cylinder speed must be

adjusted to match the length of clamp arm. The

clamping force also varies with the length of the

clamp arm. Refer to sections 3.0 and 3.1 of this

manual for operating specifications and clamp arm

length information.

2. Flow controls with return checks should be used to

reduce swing cylinder speed to the recommended

rate. The return checks help minimize back pressure

that could lead to an unclamp malfunction on single-

acting systems.

3. When using single-acting swing cylinders, limit

the return flow back pressure to 3,5 bar [50 psi]

maximum. Large diameter tubing (10 mm [3/8 in.]

O.D. or larger) and flow controls with free flow

return checks help minimize back pressure. Consult

Enerpac for proper system design.

4. An excessive retract flow rate can cause damage

to the index mechanism. Double acting systems

should be set up with a metered-in flow control, with

a reverse check used in the clamp port.

5. Clamping of the part should occur at the midpoint

of the vertical travel. No clamping of part shall occur

while the swing cylinder clamp is turning. Clamp arm

should freely travel during the 90° rotation (avoid

contact with cutter heads, tools, etc.).

6. Attaching clamp arm to cylinder plunger must be

done according to the instructions in Section 6.4.

5.0 MOUNTING SPECIFICATIONS

5.1 Mounting Upper Flange Cylinders

The Enerpac 70 bar swing cylinders feature an upper

flange design. The cylinder can be mounted to the fixture

using the supplied mounting bolts. Oil can be supplied

to the cylinder using either the BSPP hydraulic ports on

the flange or the O-Ring manifold ports on the underside

of the flange. The sections that follow provide detailed

mounting instructions and should be reviewed before

attempting to install the cylinders on the fixture.

WARNING: The fixture must be capable of

withstanding 70 bar [1000 psi] hydraulic

working pressure when the cylinders are

manifold mounted.