Enerpac SU7-Series User Manual

Page 7

7

J

63

J2

0.004

Manifold

O-Rings

(included)

Mounting Bolts

(included)

0,5mm x 45º

ø 4,8mm

ø D3

Mtg. Hole

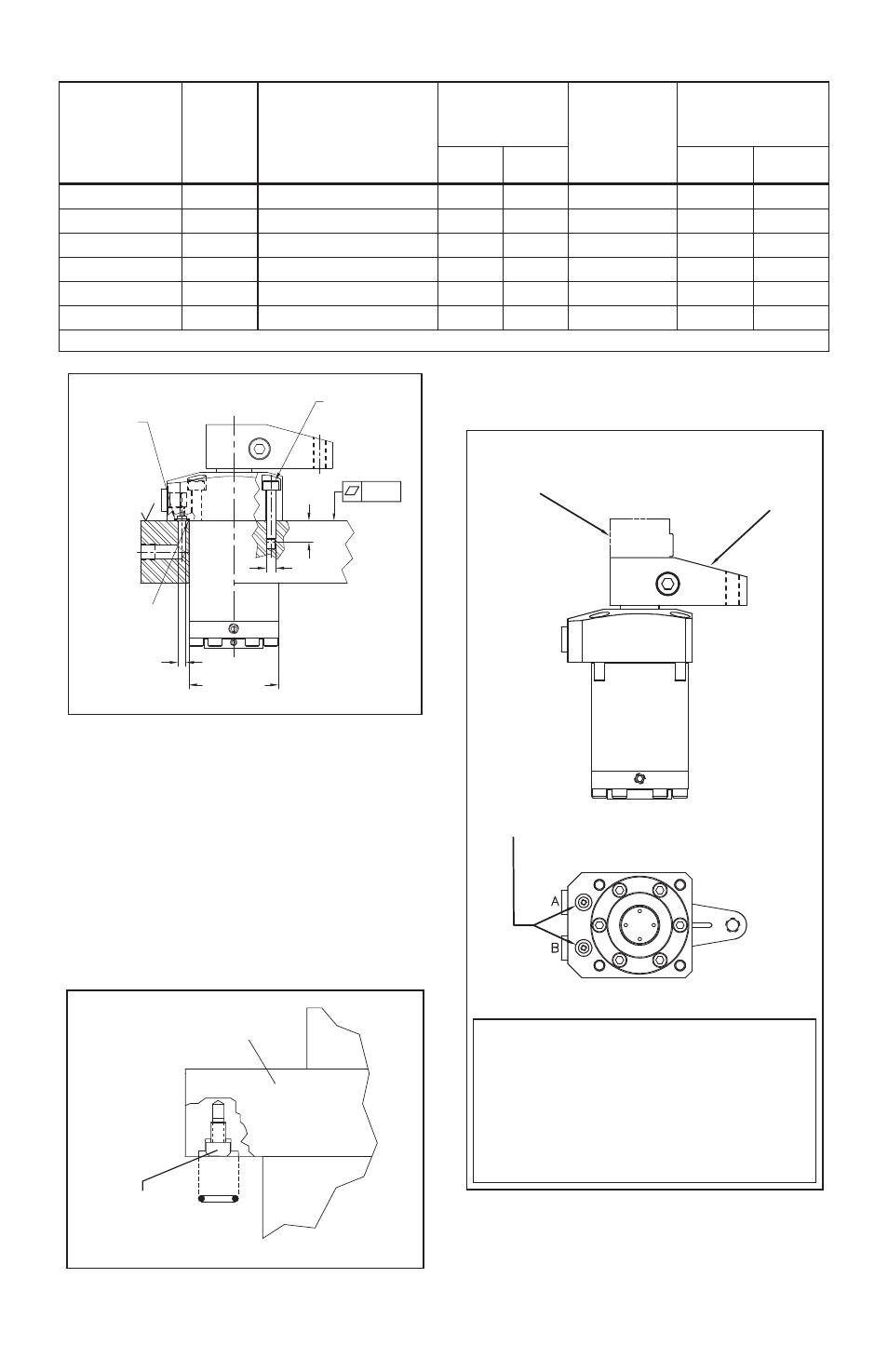

Figure 1, Cylinder Mounting Details

Before a swing cylinder can be manifold mounted,

the port screw plugs must be removed. The O-Rings

provided should be lubricated and installed in the

counter-bore around the port prior to mounting and

bolting down the swing cylinder.

Be sure that the O-Ring does not get pinched or

damaged during mounting as leakage could result. To

prevent leakage from the manifold mounting, provide

a fixture mounting surface with latness within 0,08 mm

[0.003 inch] and a surface roughness not to exceed

Ra 1,6.

Port Screw Plug

(remove)

O-Ring

Upper Flange

Figure 2, Port Screw Plug Removal

6.0 INSTALLATION

6.1 Port Identification

KEY:

A Port: Plunger rotates 90 ° and clamps

B Port: Double-acting -- Plunger unclamps and

rotates -90 °

Single-acting -- Vent Port

Do not remove vent plug except to attach tubing.

(see Section 6.3 for additional information)

SIDE VIEW

BOTTOM VIEW

Manifold

Ports

“Unclamp”

Position

“Clamp”

Position

Figure 3, Cylinder Port Locations

Table 10 - Mounting Dimensions (Refer to Figure 1)

Cylinder

Capacity

Fixture

Thread

Ø D3

mm

Mounting Bolt

Thread (J)

Minimum

Mounting

Depth (J2)

Manifold

O-ring

ARP No.

Lubricated Bolt

Torque

mm

inch

Nm

ft-lbs

2,0 kN [441 lbs]

44,5

M5 x 0,8 x 30 mm long

10

0.39

568-010

8,0-9,0

5.9-6.6

3,5 kN [769 lbs]

50,5

M5 x 0,8 x 30 mm long

11

0.43

568-010

8,0-9,0

5.9-6.6

5,0 kN [1111 lbs]

55,5

M6 x 1,0 x 30 mm long

12

0.47

568-011

13,5-15,0

10.0-11.0

7,0 kN [1570 lbs]

65,5

M6 x 1,0 x 30 mm long

15

0.59

568-011

13,5-15,0

10.0-28.0

9,0 kN [2019 lbs]

88,5

M8 x 1,25 x 30 mm long

15

0.59

568-011

32,0-38,0

23.6-28.0

20,0 kN [4490 lbs]

90,5

M10 x 1,5 x 35 mm long

20

0.79

568-011

47,9-53,1

65.0-72.0

Note: O-rings and mounting bolts included with cylinder.