Enerpac W35000 User Manual

Page 10

10

5 Maintenance and troubleshooting

Preventative maintenance can be

carried out by the user. Full

maintenance must be carried out

by an approved and authorized

technician appointed by Enerpac.

Recommended service intervals

are:

a) 3 months – Heavy Duty use

b) 6 months – Normal use

c) 12 months – Infrequent use

- Non destructive testing must be

carried out if the tool has been used

under severe conditions.

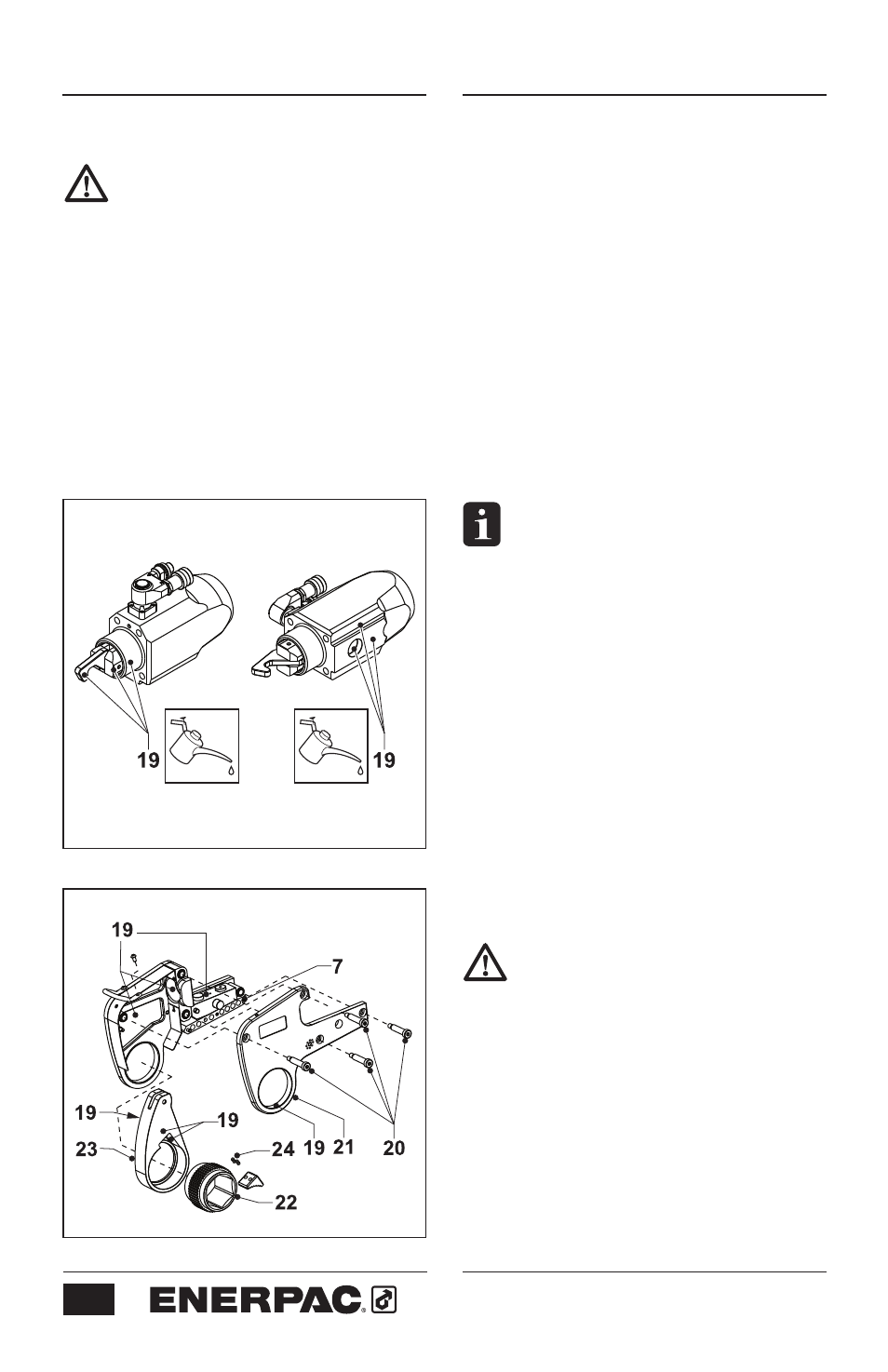

5.1 Preventative

maintenance

(fig. K & L)

5.1.1 The hydraulic drive unit

• Check tightness of swivel post

retaining screws (see 5.2.1) and

gland.

• Pressurize the drive unit to maximum

pressure (Advance and Retract), and

check for any signs of leakage.

• Any damaged components or seals

must be replaced.

• Dry all components and apply a thin

coat of molybdenum disulphide as

indicated (19).

Molybdenum disulphide is

available from Enerpac.

5.1.2 The cassette

• Remove the cassette from the drive

unit.

• Remove the screws (20). Lift and

remove the sideplates (21).

• Remove the hex ratchet (22),

spring loaded drive shoe (23), and

compression springs (24).

• Clean all exposed components with a

mild solvent.

• Inspect all parts for damage.

• Dry all components. Apply a thin

coat of molybdenum disulphide as

indicated (19).

Do not apply any lubricant to the

ratchet or drive shoe teeth.

Fig. K

Fig. L