Enerpac ZA4T-Series User Manual

Page 5

5

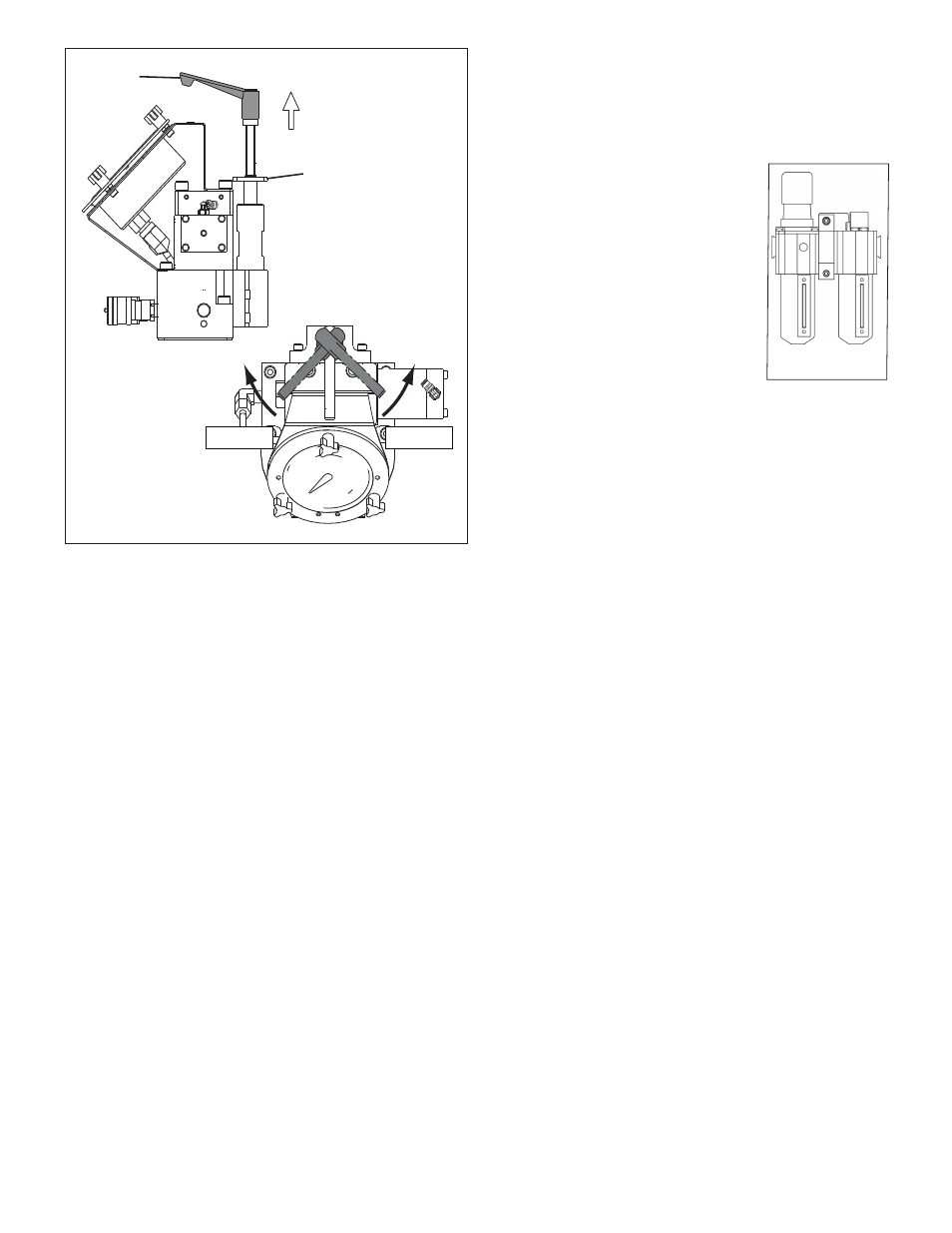

Increase

Locking Nut

Pull up to

disengage

Decrease

Figure 12, Relief Valve Adjustment

6.0 MAINTENANCE

Frequently inspect all system components for leaks or damage.

Repair or replace damaged components.

6.1 Check Oil Level

Check the oil level of the pump prior to start-up, and add oil, if

necessary, by removing the fi ll port cap. Always be sure hydraulic

wrenches are fully retracted before adding fl uid to the reservoir.

See Figure 2.

6.2 Change Oil and Clean Reservoir

Enerpac HF oil is a crisp blue color. Frequently check oil condition

for contamination by comparing pump oil to new Enerpac oil. As

a general rule, completely drain and clean the reservoir every 250

hours, or more frequently if used in dirty environments.

NOTE: This procedure requires that you remove the pump from

the reservoir. Work on a clean bench and dispose of used oil

according to local codes.

1. Unscrew the 13 bolts holding the coverplate to the reservoir

and lift the pump unit out of the reservoir. Be careful not to

damage the fi lter screen.

2. Pour all oil out of the reservoir.

3. Thoroughly clean the reservoir and reservoir magnet with a

suitable cleaning agent.

4. Remove the pick-up fi lter screen for cleaning. (Do not pull

on the screen or the bottom of the intake to avoid possible

damage.) Clean the screen with solvent and a soft brush.

Reinstall.

5.

Reassemble the pump and reservoir, installing a new reservoir

gasket.

6. Fill the reservoir with clean Enerpac hydraulic oil. The reservoir is

full when oil level is in middle of the sight gauge (see fi gure 4).

6.3 Cleaning the Muffl

er

When the pump is run for long periods of time, ice may form on

the muffl

er element and must be removed. To clean the muffl

er,

unscrew and remove any debris.

6.4 Cleaning the Air-Filter Lubricator

Inspect the air-fi lter lubricator frequently to detect for damage.

Replace damaged bowls.

Keep the fi lter bowl clean to maintain

fi ltering effi

ciency. The unit is equipped

with an automatic drain, which

opens around 3 psig and closes at

approximately 5 psig. (See Figure 13.)

A visible coating of dirt or condensate

on the fi lter element or an excessive air

pressure drop indicates that cleaning

is necessary. Depressurize the unit

before removing bowl for cleaning.

CAUTION: Clean fi

lter bowl with

household soap only.

7.0 TROUBLESHOOTING (SEE TROUBLE-SHOOTING

GUIDE)

Only qualifi ed hydraulic technicians should service the pump or

system components. A system failure may or may not be the result

of a pump malfunction. To determine the cause of the problem, the

complete system must be included in any diagnostic procedure.

The following information is intended to be used only as an aid in

determining if a problem exists. For repair service, contact your

local Authorized Enerpac Service Center.

Figure 13

Handle