Enerpac ZA4T-Series User Manual

Page 4

4

5.0 OPERATION

IMPORTANT: When possible, a single user should operate the

torque wrench and pump. This can prevent accidental activation

of the pump while the operator is positioning the wrench.

1. Check all system fi ttings and connections to be sure they are

tight and leak free.

2. Check oil level in reservoir and add oil

if necessary. (see section 4.4)

3. Make sure the shipping plug has

been removed and the breather cap is

installed. (see section 4.1)

WARNING: In the following

step, the pump motor will start

and the valve will shift

automatically, retracting the torque

wrench. Verify torque wrench is positioned

to avoid injury or equipment damage

before starting motor.

4. To start the pump, press the green

"ON/ADV" button (F) on the pendant (handset). The wrench

will advance as long as the green button is held down.

5. Release the green button to retract the wrench. The motor will

remain "ON".

6. Press the red "OFF" button (G) on the pendant to stop the

pump motor.

7.

To release hydraulic pressure on the wrench and hoses, press

and hold the red "OFF" button. Press and release the green

"ON/ADV" button 3 or more times until the pressure gauge

reads 0 pressure. The hoses can now be removed.

CAUTION: MAKE SURE THE MOTOR IS TURNED

OFF AND IS NOT RUNNING BY PRESSING THE RED

"OFF" BUTTON, BEFORE THE AIR SUPPLY SOURCE

IS TURNED OFF OR DISCONNECTED.

5.1 Air Removal

When the wrench is fi rst connected to the pump, air will be trapped

in the components. To ensure smooth and safe operation, remove

air by cycling wrench several times without load. Cycle until

wrench advances and retracts without hesitation.

Check oil level before operation.

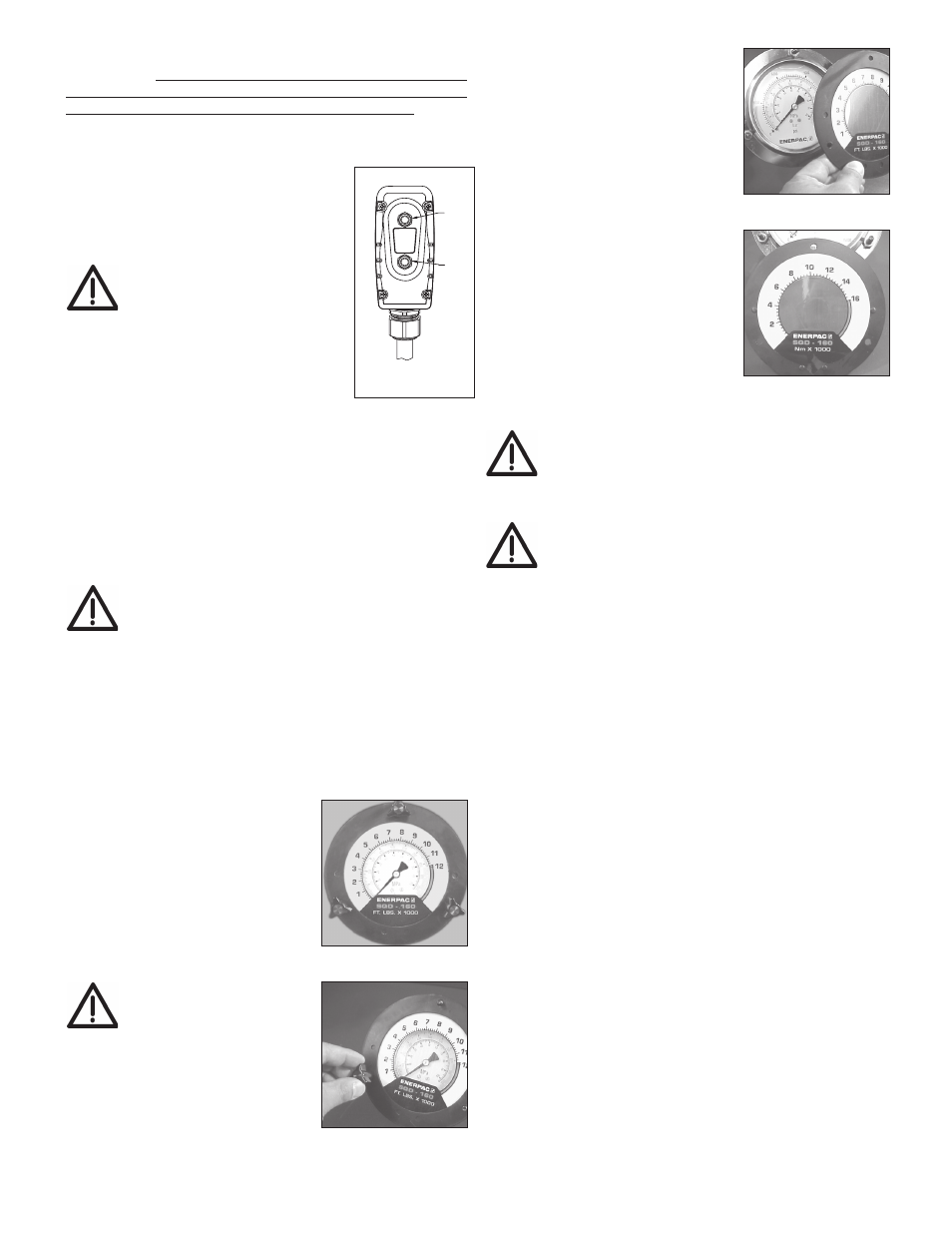

5.2 Gauge and Overlay Operation Procedure

The pump is supplied with a

pressure gauge installed. For your

convenience, torque overlays are

provided with each pump. A torque

overlay fi ts over the pressure gauge

dial face and easily converts pressure

readings to torque readings (see Fig.

8). The overlay has imperial units (Ft-

Lbs.) on one side and metric units

(Nm) on the other. To change scales

simply slip overlay over.

WARNING: Each overlay

is sized for a specifi c

Enerpac torque wrench

ONLY. Do not use with other

wrenches.

5.3 Changing the Overlay

1. Remove the three black wing

knobs which hold the front

gauge fl ange in place (see Fig. 9).

2. Remove the front fl ange and

overlay (see Fig. 10.)

3. Insert new overlay (remember to

verify correct overlay to the Enerpac

torque wrench being used) onto the

fl ange, aligning the overlay with the

dimples on the back of the fl ange

(see Fig. 11).

4.

While holding the overlay behind the

fl ange (see Fig. 10.) insert the fl ange

onto the knob studs, repositioning

the overlay as needed, and secure

knobs fi nger tight (see Fig. 9).

The fl ange will press the overlay

onto the gauge and secure it

in place. See torque wrench

instructions for amount of pressure

required to produce desired torque.

Note that the maximum pressure

varies for diff erent wrenches and

accessories.

CAUTION: Refer to torque wrench instructions for

wrench operating procedure.

5.4 Pressure (Torque) Setting

WARNING: Make these adjustments BEFORE putting

torque wrench on nut or bolt head. The pump pressure

setting may not be above the pressure needed to

provide the required torque for your application. Exceeding

required torque will cause equipment damage and may lead to

serious personal injury.

To limit the advance pressure to the torque wrench, adjust the

relief valve as described in the following procedure. See Figure 12.

1. Loosen the relief valve locking nut.

2. Rotate relief valve handle counter-clockwise as required, until

there is little or no resistance when turning. When this occurs,

the valve is at its lowest setting.

Note: Relief valve handle will rotate only about two thirds of a full

turn. When rotation stops, pull up on handle to disengage. Then,

reposition and re-engage handle to allow additional adjustment

(as required).

3.

Press and hold the pendant “ON/ADV” button. Motor will start

and pressure will begin building in the A-Port advance circuit.

4.

While continuing to hold down the “ON/ADV” button, SLOWLY

rotate relief valve handle clockwise, until pressure increases

to the desired setting.

Note: To obtain an accurate setting, always decrease the pressure

to a point below the fi nal setting and then slowly increase the

pressure until the fi nal setting is reached.

5.

Release the “ON/ADV” button to allow the system pressure to

return to the B-port retract setting. The motor will continue to

run.

6. Press and hold the “ON/ADV” button again to recheck the

advance circuit pressure setting. Verify that the desired

pressure is indicated on the pressure gauge.

7. After the desired pressure setting has been obtained, tighten

the relief valve locking nut.

F

G

OFF

ON/ADV

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11