Ii 2 gd ck t4 – Enerpac ZA4T-Series User Manual

Page 2

2

CAUTION: Keep hydraulic equipment away from

fl ames and heat. Excessive heat will soften packings

and seals, resulting in fl uid leaks. Heat also weakens

hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C [150°F] or higher.

Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

WARNING: Only use hydraulic cylinders in a coupled

system. Never use a cylinder with unconnected couplers. If

the cylinder becomes extremely overloaded, components

can fail catastrophically causing severe personal injury.

WARNING: BE SURE SETUP IS STABLE BEFORE

LIFTING LOAD. Cylinders should be placed on a fl at

surface that can support the load. Where applicable, use

a cylinder base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Avoid situations where loads are not directly centered

on the cylinder plunger. Off -center loads produce

considerable strain on cylinders and plungers. In

addition, the load may slip or fall, causing potentially dangerous

results.

Distribute the load evenly across the entire saddle

surface. Always use a saddle to protect the plunger.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualifi ed hydraulic technician. For repair

service, contact the Authorized ENERPAC Service

Center in your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fi t properly and withstand high

loads.

WARNING: Start the pump with the valve in the

neutral position to prevent accidental cylinder

operation. Keep hands clear of moving parts and

pressurized hoses.

WARNING: These pumps have internal factory

adjusted relief valves, which must not be repaired or

adjusted except by an Authorized Enerpac Service

Center.

3.0 SPECIFICATIONS

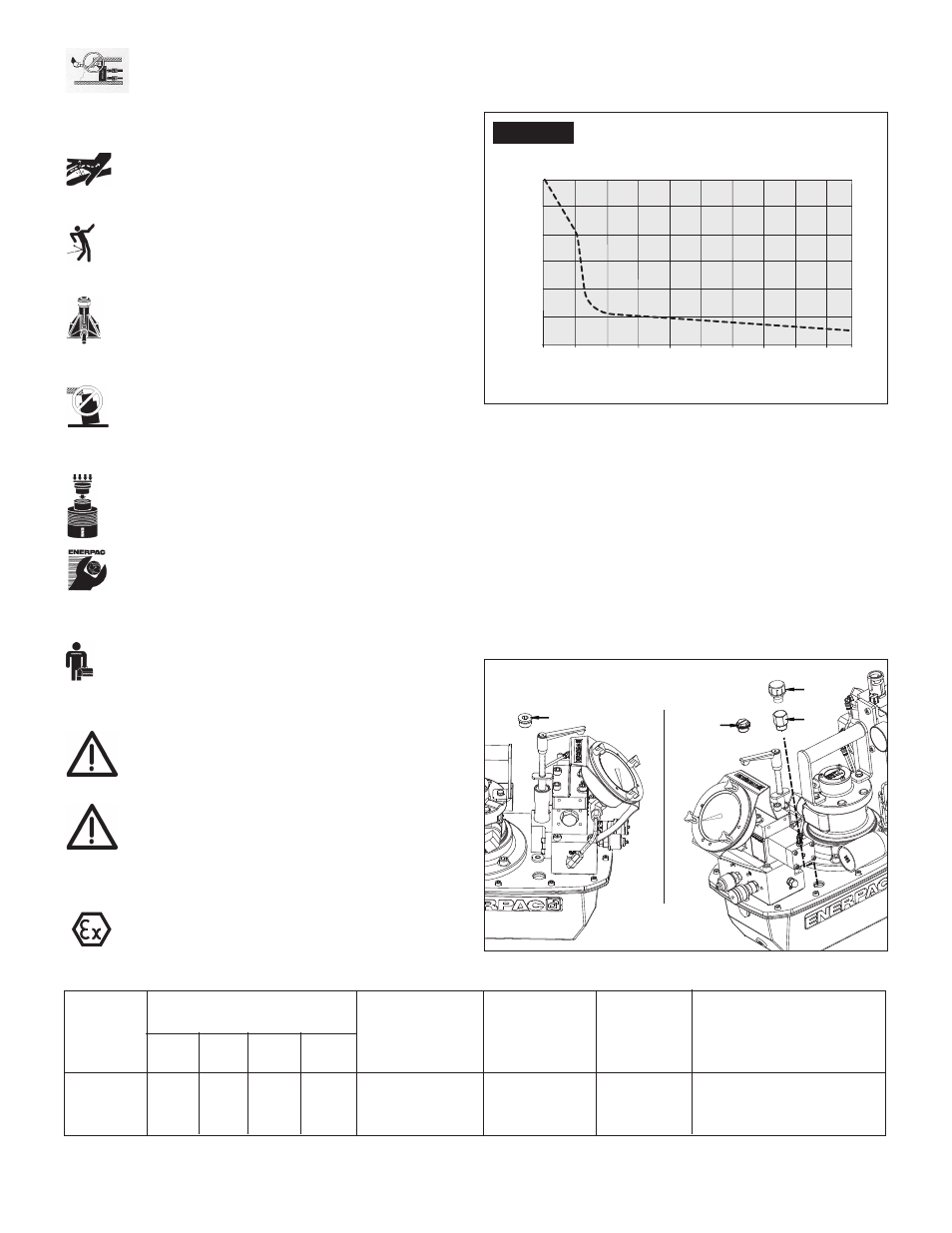

3.1 Performance Chart (see Performance Chart below)

3.2 Flow Chart

Pressure (psi)

Flow vs. Pressure

100 psi dynamic air pressure

@ 70 scfm air consumption standard muffl

er

Figure 1

Flow (in

3

/min)

Figure 1

4.0 INSTALLATION

Install or position the pump to ensure that air fl ow around the

motor and pump is unobstructed. Keep the motor clean to ensure

maximum cooling during operation.

4.1 Breather Cap and Oil Fill Plug (See Figure 2)

A shipping plug (A) is installed in the breather port on the top of

the reservoir. Before using the pump, replace the shipping plug

(A) with the breather cap (B) and adapter fi tting (C). Note: The oil

fi ll port is located on the opposite side of the pump. The oil fi ll

port uses an SAE #10 plug (D).

Figure 2, Oil Fill Plug and Breather Cap

D

A

B

C

II 2 GD ck T4

600

500

400

300

200

100

0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Motor

Size

(hp)

4*

Output Flow Rate

in3/min

100

700

5,000 10,000

psi psi psi psi

600

500

80

60

Dynamic Air

Pressure Range

(psi)

60-100

Air

Consumption

(scfm)

20-100

Sound Level

@ 100 psi

dynamic

(dBA)

80-95

Relief Valve

Adjustment

Range

(psi)

1,400-10,000 for "Q" version

1,400-11,600 for "E" version

*Actual power consumption depends on the application. See Figure 1.

▼ ZA4T PERFORMANCE CHART