Integrating the hornet or bee on a pcb, Traces, Grounds and returns – ElmoMC ExtrIQ Digital Servo Drives-Hornet User Manual

Page 23: Traces 3.5.2. grounds and returns

Hornet and Bee Installation Guide

Installation

MAN-HRBEIG (Ver. 1.304)

23

3.5. Integrating the Hornet or Bee on a PCB

The Hornet and Bee are designed to be mounted on a PCB, either by soldering the pins directly

to the PCB or by using suitable socket connectors. In both cases the following rules apply:

3.5.1.

Traces

1.

The size of the traces on the PCB (thickness and width) is determined by the current

carrying capacity required by the application.

The rated continuous current limit (Ic) of the Hornet and Bee is the current used for

sizing the motor traces (M1, M2, M3 and PE) and power traces (VP+, PR and PE).

For control, feedbacks and Input/output conductors the actual current is very small but

“generous” thickness and width of the conductors will contribute to a better

performance and lower interference.

2.

The traces should be as short as possible to minimize EMI and to minimize the heat

generated by the conductors.

3.

The spacing between the high voltage conductors (VP+, PR, M1, M2, M3, VL) must be at

least:

Surface layer: 1.5

mm

Internal layer: 0.10 mm

Complying with the rules above will help satisfy UL safety standards, MIL-STD-275 and the IPC-

D-275 standard for non-coated conductors, operating at voltages lower than 100 VDC.

3.5.2.

Grounds and Returns

The “Returns” of the Hornet and Bee are structured internally in a star configuration. The

returns in each functional block are listed below:

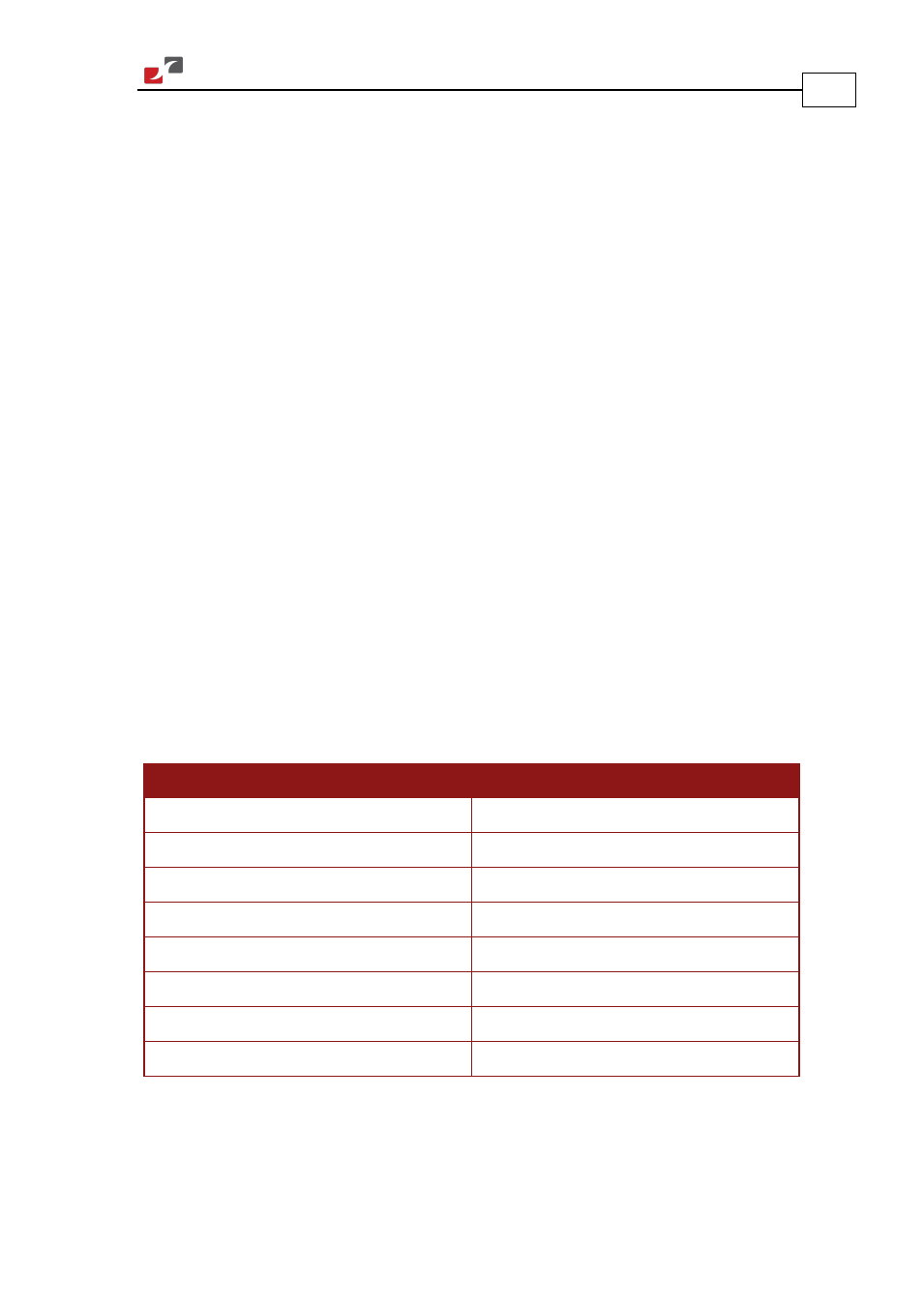

Functional Block

Return Pin

Power

PR (Power Return)

Internal Switch Mode P.S.

PR (Power Return)

RS232 Communications

RS232_COMRET (J1/3)

CAN Communications

CAN_COMRET (J1/20)

Control section

Internal, not accessible

Main Feedback

SUPRET (J2/2)

Aux. Feedback

SUPRET (J1/4)

Analog input

ANLRET (J2/2)

The returns above are all shorted within the Hornet or Bee in a topology that results in

optimum performance.