Dakota Ultrasonics PVX User Manual

Page 72

68

CHAPTER EIGHT

THRU PAINT MEASUREMENT TECHNIQUE

8.1 Introduction to Thru Paint Measurement

The principle behind thru paint measurement is by measuring the time between two

backwall echoes returning from the test material. Since both of these backwall

echoes travel the same path through the paint or coating, the thickness of the coating

is subtracted out of the measurement so that only the actual material thickness can

be measured. This feature saves the user a great deal o f time scraping and

removing the coating from various test materials during the inspection process. The

primary purpose of thru paint measurement is to determine actual or overall material

thickness by eliminating the coating thickness.

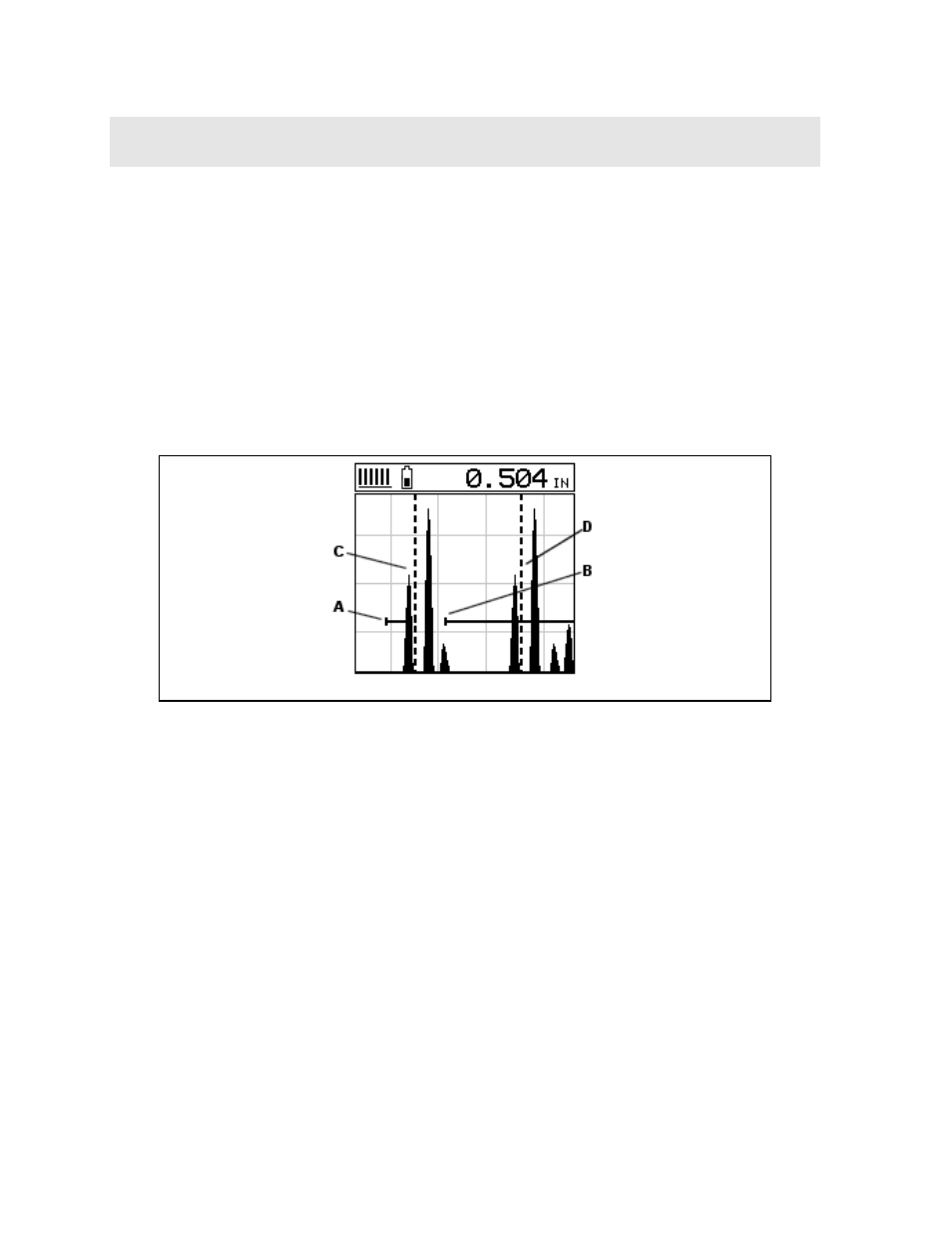

ECHO – ECHO MODE (THRU PAINT ) – TWO GATES

Refer to the diagram above. This is a typical example of an echo-echo mode setup

commonly used for a through paint or coatings application. Once again, the

definition of an echo -echo measurement, is a measurement taken between to return

echoes, rather than from the initial pulse to a single echo. Therefore, the

measurement is taken between the first and second echo reflections. Point (C)

represents the detection on the back wall of the first reflection. Notice that GATE1

has been has been set up so that the PVX can only see the first back wall reflection

(C), and cannot see anything before the first reflection. Remember that the PVX can

only see those signals inside the dimensions of the gate.

GATE2 (hold-off) has been set at point (B), so that the transducer ring down noise

following the first detection (C) can’t interfere with the second back wall reflection (D).

The distance from point (C), which is the end of the first gate (A), to the start of

GATE2 (B), is the hold-off time or delay. This type of setup allows the user to

eliminate the paint or coating, and measure only metal the thickness of the metal.

8.2 Setting Up Thru Paint Mode