Warning, Danger – COATS 6060 AX/EX Tire Changer User Manual

Page 10

T. If tire and wheel are properly lubricated and

operator cannot achieve bead seal after 3 or 4

attempts, the valve core may be removed from the

valve stem to allow more air flow into the tire to

assist with bead seal. After bead seal is achieved,

remove the chuck and reinstall the valve core.

Bead Seating

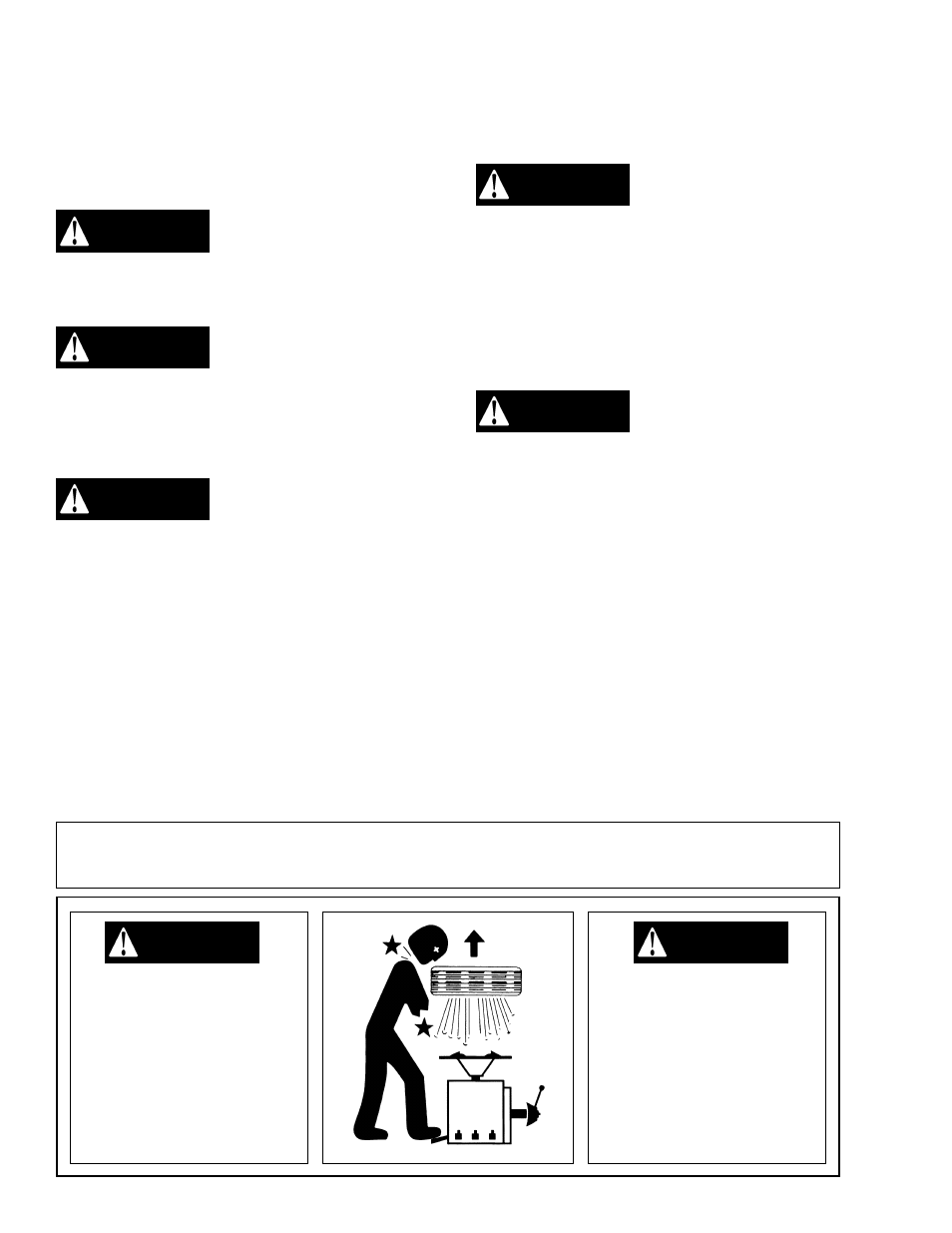

Operator should always stand

behind Inflation Guard and keep

hands, arms, and entire body

away from the tire during the remaining bead seat and

inflation procedures. Do not permit anyone to stand over the

tire as personal injury could result.

Operating a tire changer with a

defective, improperly adjusted,

or by-passed pressure limiter

could cause an operator to accidentally over-pressurize a

tire, resulting in a tire explosion with severe injury or death

to the operator or bystanders. Always be sure that the

pressure limiter is present and is operating properly on the

machine at all times.

NEVER increase air pressure to

exceed 40 PSI when attempting

bead seat. If operator is unable

to obtain bead seat, something is wrong. Deflate tire

completely, inspect the tire and wheel for defects and make

sure that the tire and wheel size match. Correct any

problems found, relubricate both tire beads, and reattempt

bead seal and seating procedures.

1.

Once the tire is sealed to the rim, move to the

area behind the Inflation Guard and push the

inflation valves simultaneously. Both valves

must be actuated to inject air into the tire.

Continue to inject air into the tire in short

intervals, checking the pressure frequently.

Stand behind Inflation Gaurd during bead seat.

Keep hands, arms, and entire body away from

tire during this procedure.

Tire beads should move outward and "pop" into

their bead seat position as pressure inside the

tire increases. If this does not happen, a

problem exists. Investigate carefully for defects

and make sure the tire and wheel sizes match.

Check tire pressure frequently.

Never exceed 40 PSI while

seating beads. Once seated,

never exceed tire manufacturer's recommended air pressure.

Tires can explode, especially if they are inflated beyond their

limits. At all pressure levels when inflating through the valve

stem, stay behind the Inflation Guard and keep hands, arms,

and entire body away from inflating tire. An exploding tire,

wheel, or bead sealing equipment may propel upward and

outward with sufficient force to cause serious injury or death

to operator or bystander.

Inflation

NEVER exceed tire

manufacturer's recommended

air pressure. Tires can explode,

especially if inflated beyond these limits. Stay behind

Inflation Guard and keep hands, arms, and entire body back

from inflating tire. Avoid distraction during inflation. Check

tire pressure frequently to avoid over inflation. Excessive

pressure can cause tires to explode, causing serious injury

or death to operator or bystander.

1.

Make sure both beads are seated. When both

beads are seated, the tire is ready for inflation.

2.

Replace the valve core if it was removed.

3.

Depress inflation valves simultaneously and

hold to inflate tire. Pressure limiter will cycle the

air flow as described earlier. On most passenger

car tires, the pressure limiter will cease air flow

at approximately 60 PSI. On smaller volume

tires the pressure may be higher.

U. Release air pressure from tire by pressing the

manual release valve button (inflation hose must be

attached to the valve stem, Figure 18).

8 • COATS 6060AX/EX Rim Clamp Tire Changer

WARNING

WARNING

Explosion Hazard

Never exceed 40 PSI

while seating beads.

Explosion Hazard

Never inflate tire

above manufacturer’s

recommended

pressure after bead is

seated.

DANGER

DANGER

DANGER

DANGER

IMPORTANT: When inflating tires that require more than 60 PSI, always use a safety cage and an air hose with

a clip-on air chuck and an in-line valve. The hose must have enough length between the chuck and the

operator/in-line valve to allow the operator to stand outside the trajectory.

DANGER