General information, Technical data, General safety regulations – COATS CDH-9551 Electric-Hydraulic Tire Changer User Manual

Page 3: Safety devices, Transport

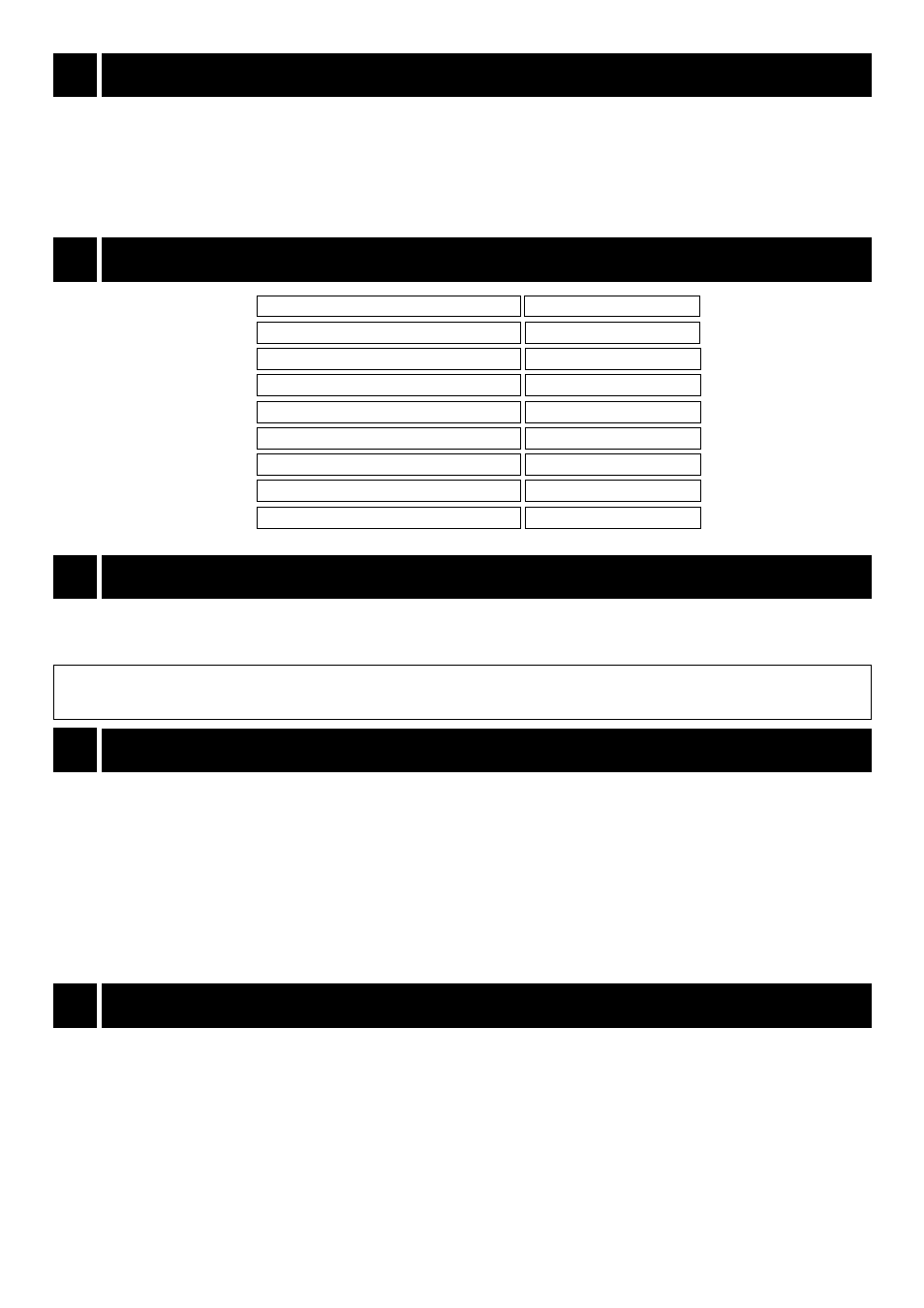

Pump motor

Gear-box motor

Handles rim from

Max. wheel diameter

Max. wheel width

Max. wheel weight

Weight (with standard accessories)

Acoustic pressure level (at work)

1,1 kw

1,8 / 1,85 kw

14" - 56"

2.400 mm

1.300 mm

1800 kg

1025 Kg

LpA <70 dB (A)

GENERAL INFORMATION

1

This tyre changer has been specifically designed to demount and mount truck, bus and commercial van tyres, with rims from

14" to 56"

and a

maximum 2.400 mm diameter.

Any other use is improper and therefore not authorized. Before beginning any kind of work on or with this machine, carefully read and

understand the contents of these operating instructions.

The manufacturer shall not liable for any injury to persons or damage to things caused by improper use of this machine.

KEEP THIS MANUAL NEAR THE MACHINE AND CONSULT IT AS NEEDED DURING OPERATIONS.

Any work, however minor, on the electric system must be done exclusively by professionally qualified personnel.

2

TECHNICAL DATA

3

GENERAL SAFETY REGULATIONS

The use of this machine is reserved to specially trained and authorized personnel.

Any unauthorized changes or modifications to the machine, in particular to its electric system, relieve the manifacturer from all liability.

Removing or tampering with the safety devices installed on this machine is in violation of European Safety Regulations.

4

SAFETY DEVICES

The tire changer has a number of safety devices designed to guarantee the utmost operator safety:

1. Check valve on the spindle opening hydraulic line (inside the swivel connector, see fig. B/1). This prevents the wheel from falling from

the spindle if the hydraulic line is accidentally broken.

2. Pressure relief valve factory set at 1.885 PSI (130 bar ±10%) (See Fig. B/2).

This limits the pressure in the hydraulic circuit and ensure correct operation of the plant.

3. Pump motor overload shut-out (inside the electric enclosure).

This provides automatic shut-off for the motor to prevent damage from overheating.

TRANSPORT

5

The machine is delivered in a wooden crate with pallet

The machine must be handled with a fork-lift truck with the forks positioned as shown in the figure A/2.

Shipping weight for the machine is 2.745 lbs (1245 kg.)

Electric Power requirement

220V - 3 PH - 60Hz 15 Amp